Steel pipe mounting base and mounting method

A technology for installing bases and steel pipes, which is applied to building components, building insulation materials, earthquake resistance, etc., can solve problems such as low construction efficiency and damage, and achieve the effect of convenient construction, high efficiency, and strengthened constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

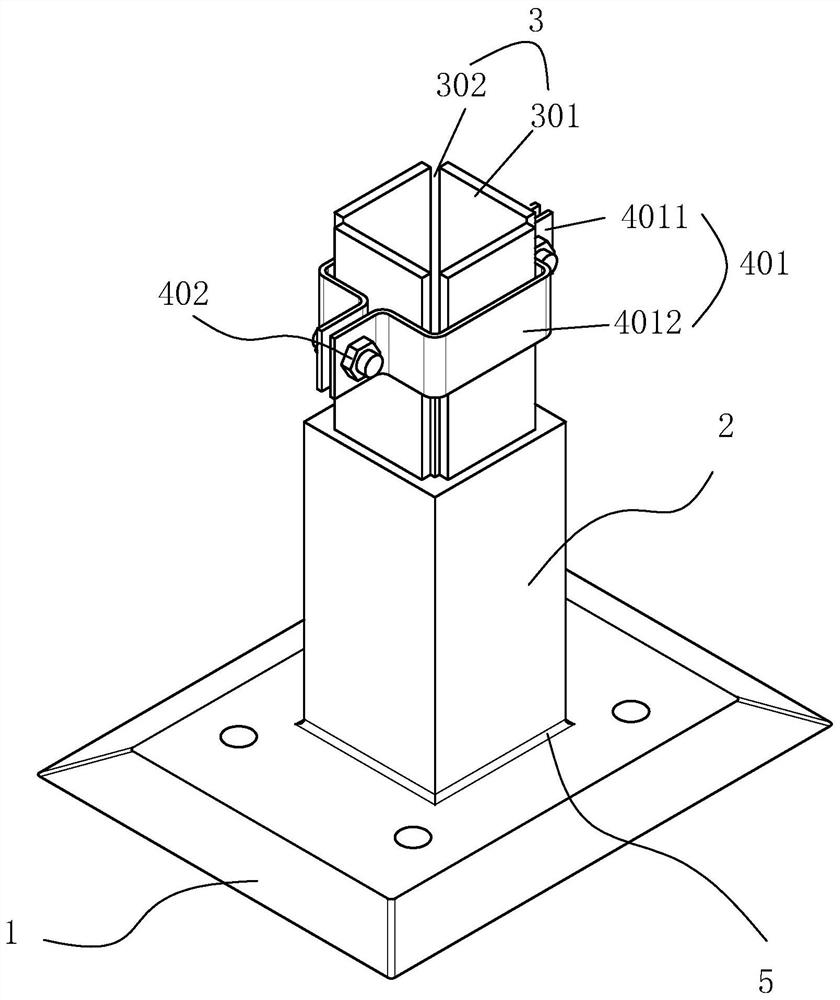

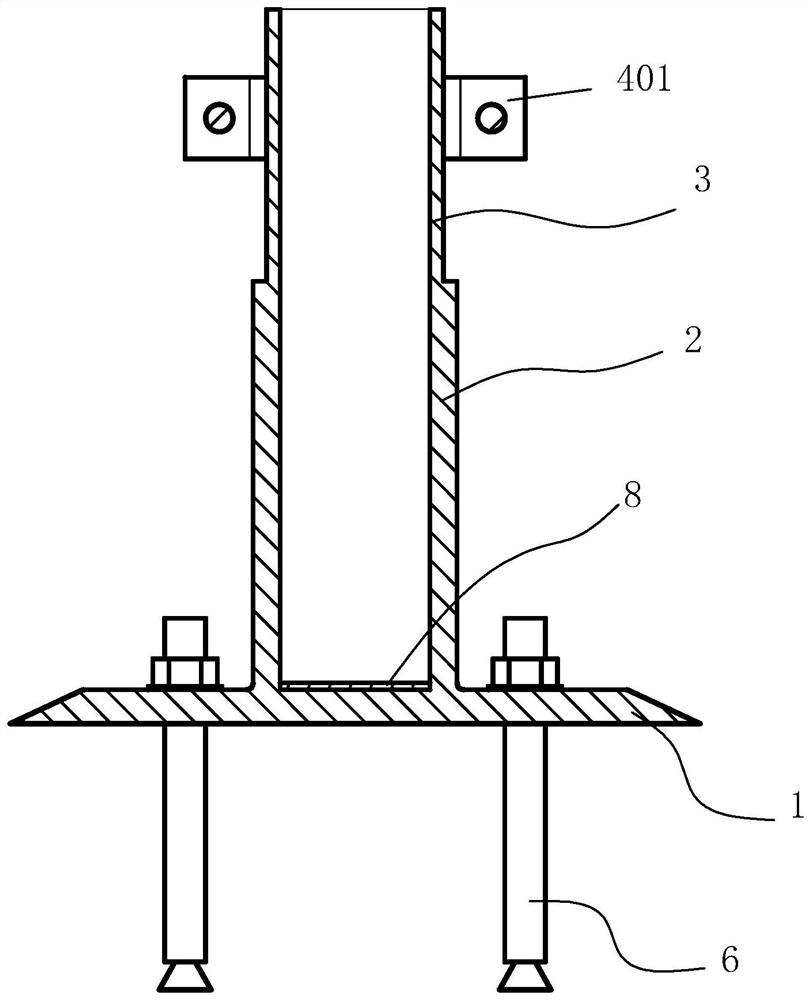

[0035] Such as figure 1 , figure 2 In the shown embodiment 1, a steel pipe installation base includes an integrated chassis 1 and a vertical pipe 2, the vertical pipe 2 is arranged perpendicular to the chassis 1, the steel pipe 7 is inserted into the vertical pipe 2, and the vertical pipe 2 is far away from the The upper end of the chassis 1 is provided with a limit guide structure 3, the limit guide structure 3 includes a number of limit pieces 301 uniformly arranged along the circumferential direction of the upper end surface of the standpipe 2, there are gaps 302 between adjacent limit pieces 301, the limit The guide structure 3 also includes a hoop assembly for reinforcing the steel pipe 7. The hoop assembly includes a pair of reinforcement plates 401 and a fixing piece 402 for fixing the two reinforcement plates 401. Here, the fixing piece 402 is a bolt structure.

[0036] In this technical solution, the chassis 1 is used to fix the ground, and the vertical pipe 2 is us...

Embodiment 2

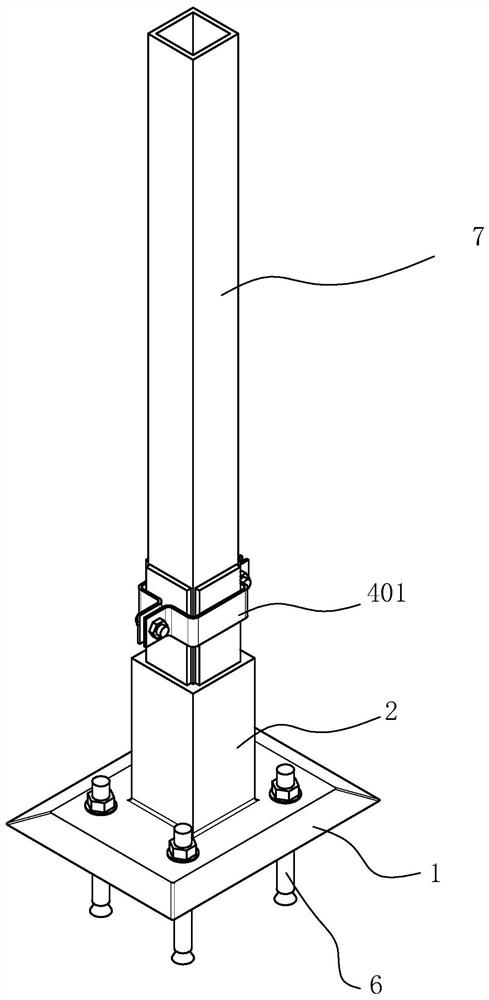

[0043] Such as image 3 As shown, embodiment 2 is a steel pipe installation method in which steel pipes are installed using the steel pipe installation base, comprising the following steps:

[0044] Step 1: Position and set out the chassis 1, and then fix the steel pipe installation base on the ground with expansion screws 6;

[0045] Step 2: Insert the steel pipe into the vertical pipe 2 and fix it once;

[0046] Step 3: Use the hoop assembly to constrain and fix the steel pipe to complete the connection between the steel pipe and the ground.

[0047] In this installation method, the installation base is positioned and laid out and then fixed by Pang Zhang screws, the assembly speed is fast, the steel pipe is directly inserted into the vertical pipe 2 and fixed by the hoop assembly, which will not cause damage to the steel pipe itself, and The fixing is firm to ensure the connection rigidity of the steel pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com