Patents

Literature

141results about How to "Reach the limit effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

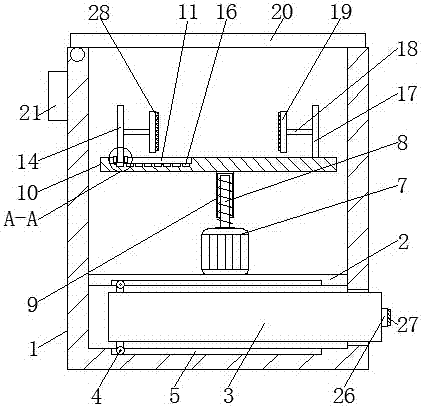

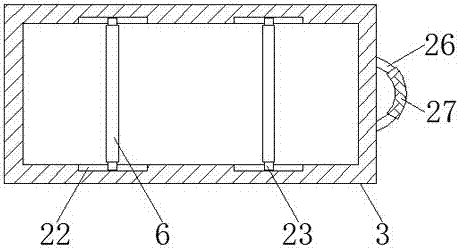

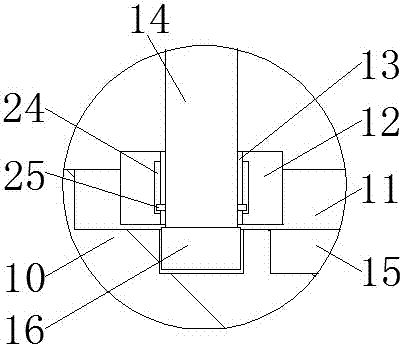

Adjustable charging pile for automobiles, method and application

InactiveCN106740245AEasy to adjustImprove efficiencyCharging stationsMobile unit charging stationsEngineeringSlide plate

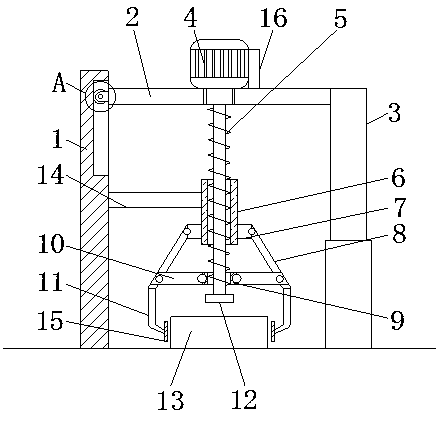

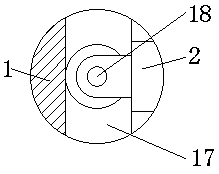

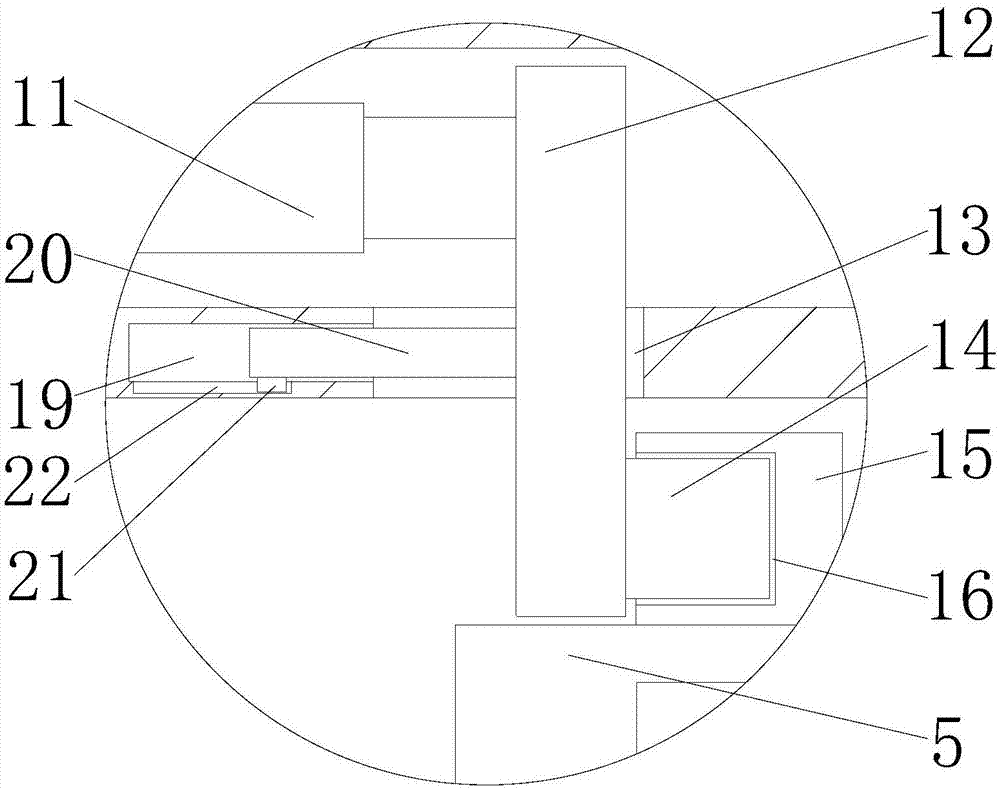

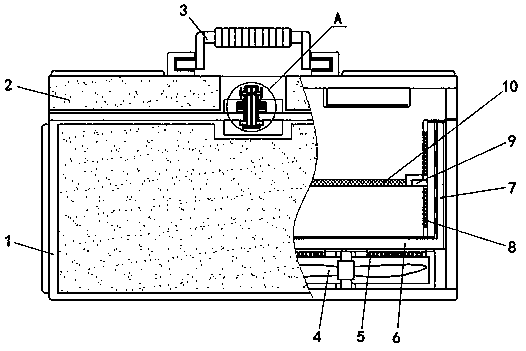

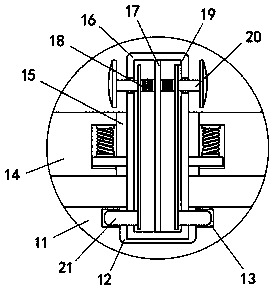

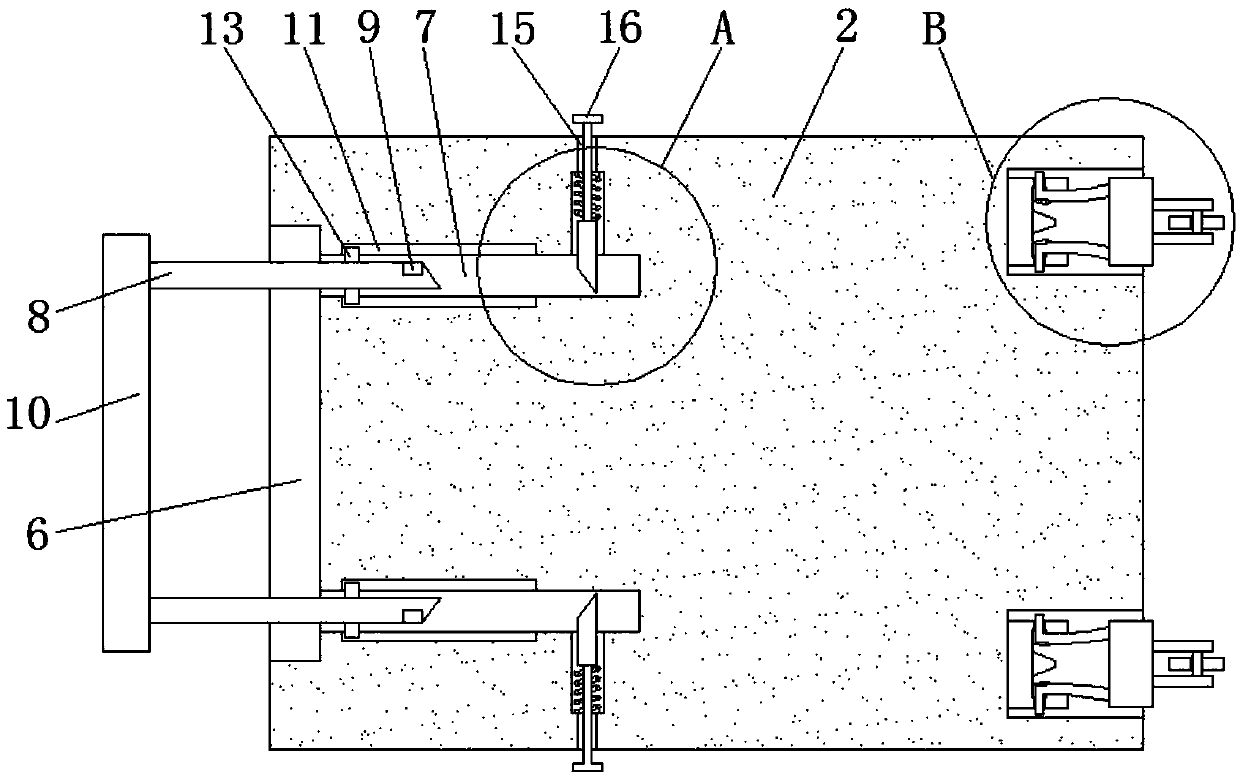

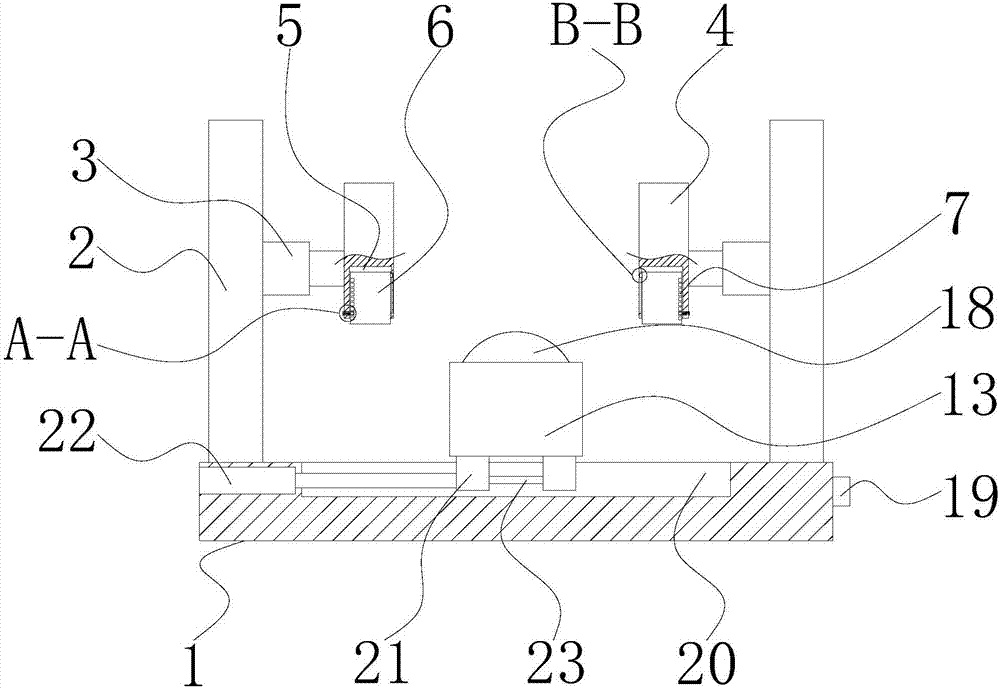

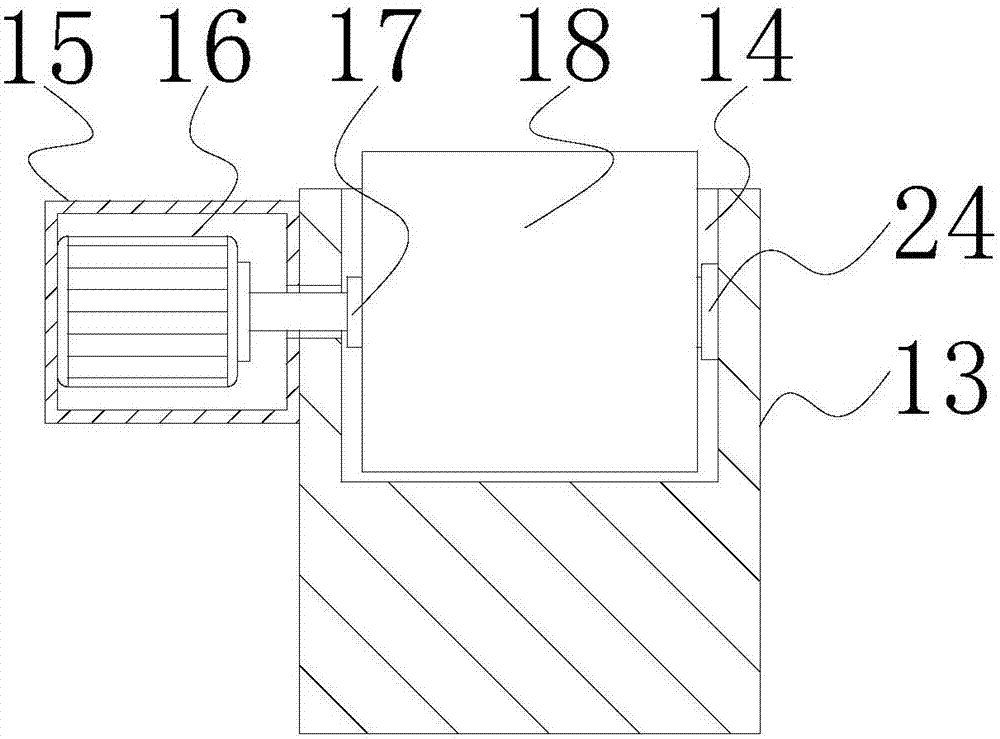

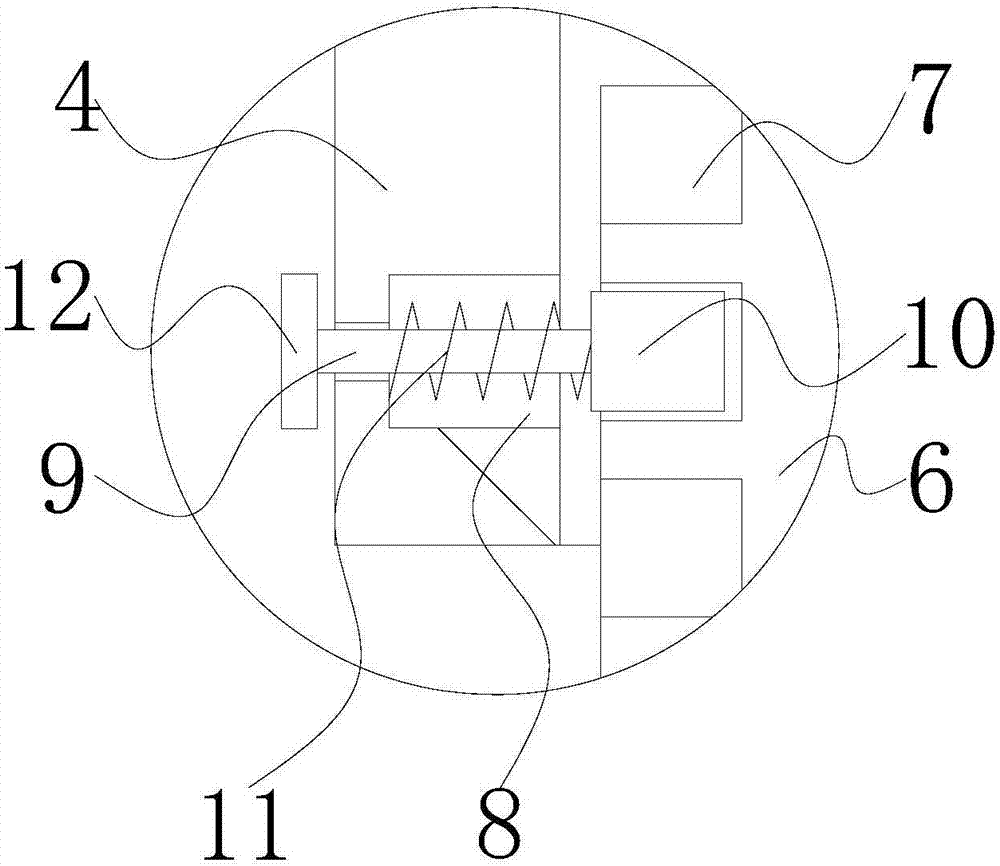

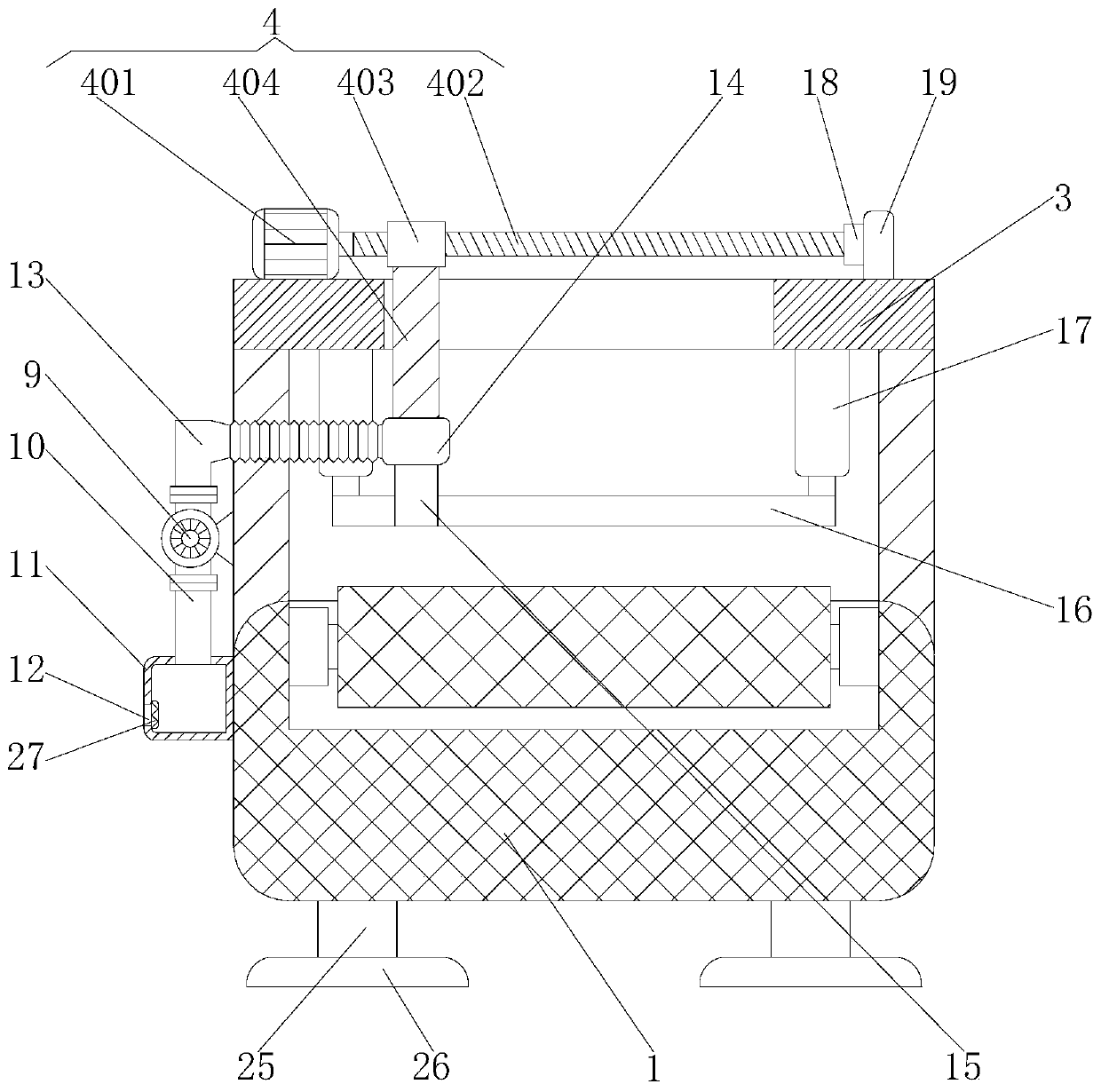

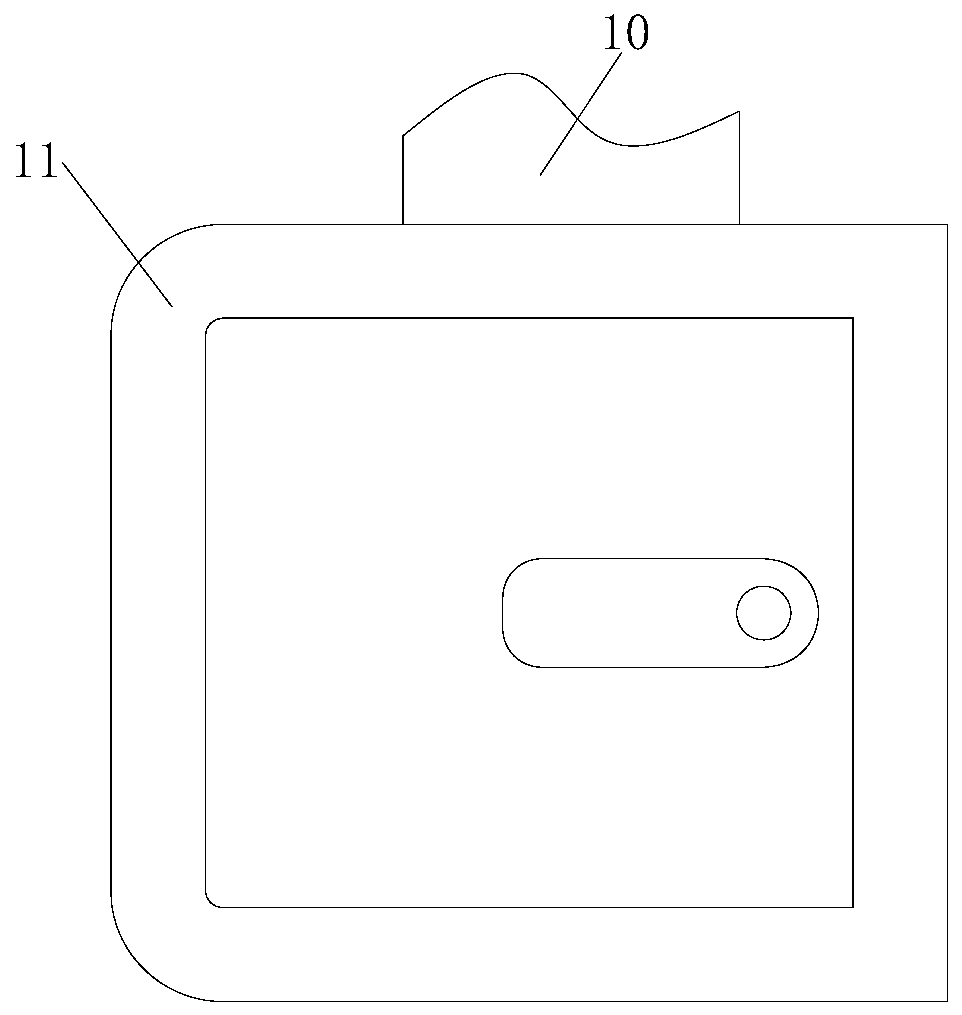

The invention provides an adjustable charging pile for automobiles, a method and application and relates to the field of automobile charging piles. The adjustable charging pile comprises a base. Buffer plates are fixed to the two sides of the top of the base. Supporting rods are fixed at the top of the buffer plates. The top ends of two supporting rods are fixedly connected with each other through a crossbar. A box body is fixed at the bottom of the crossbar and between the two supporting rods. A support stand is fixed at the top of the inner cavity of the box body. The bottom of the support stand is flexibly connected with a connection rod through a rotating shaft. Under the improvement of the box body and the function of the support stand, the connection rod, a vertical rod, a first sliding rail , a sliding plate, an inserting rod, a motor, a screw rod, nuts, a deflector rod , a second sliding rail and a sliding rod, height adjustment of a charging head of the automobile charging pile is achieved to bring convenience to users and improve the usage efficiency of the automobile charging pile.

Owner:北京畅的科技开发有限公司

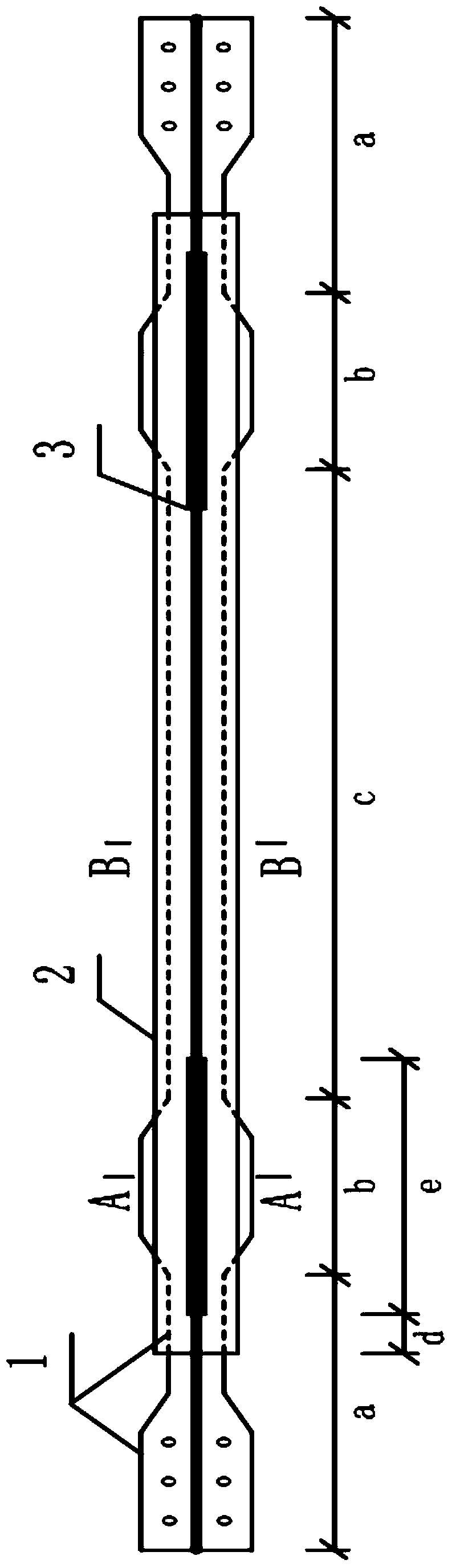

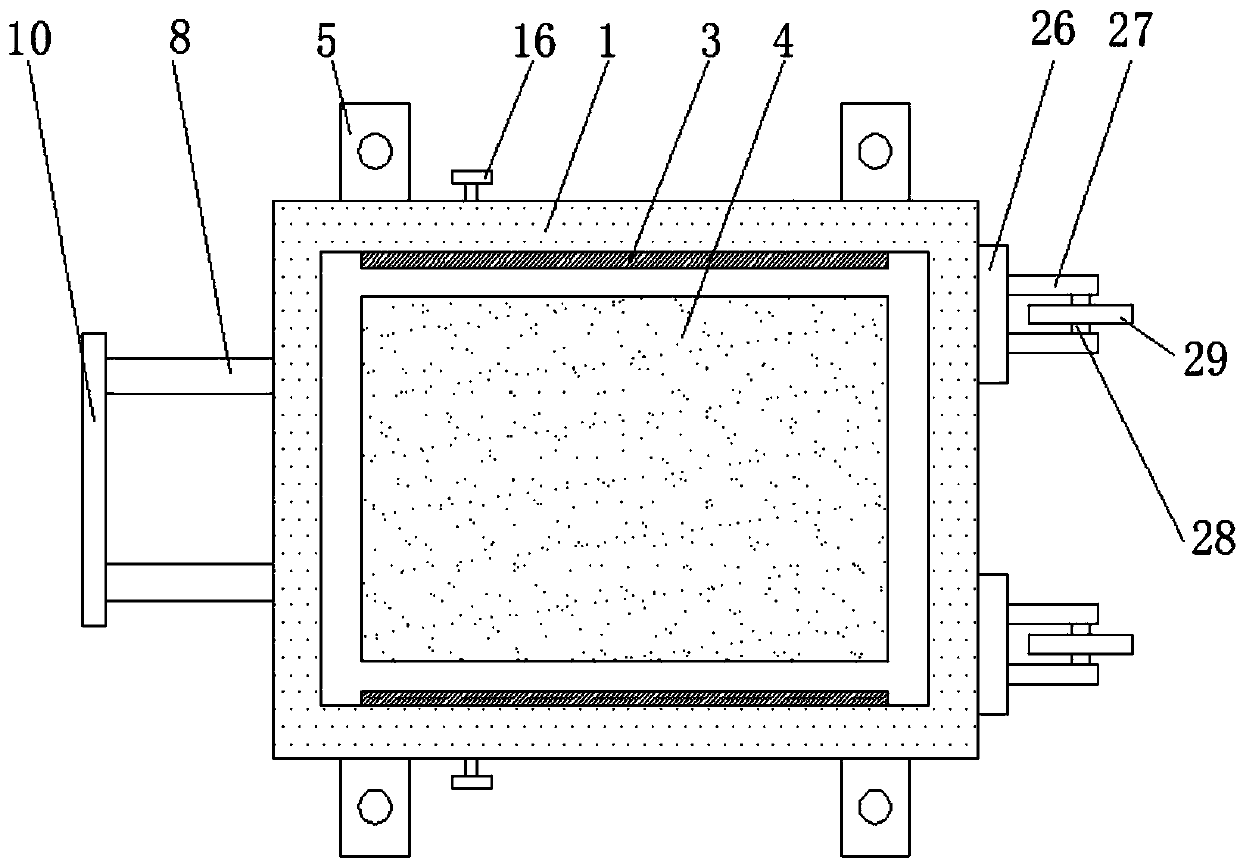

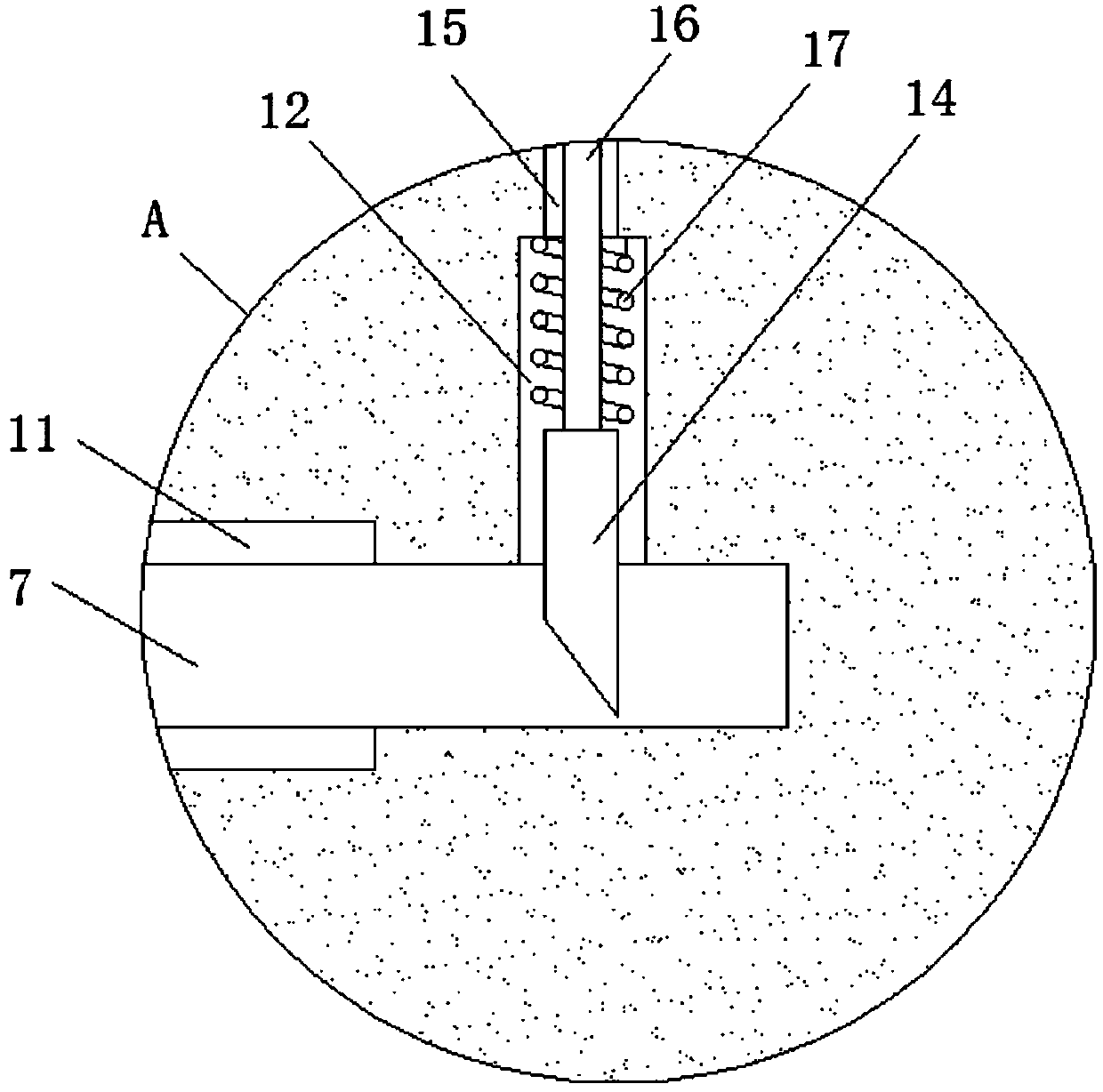

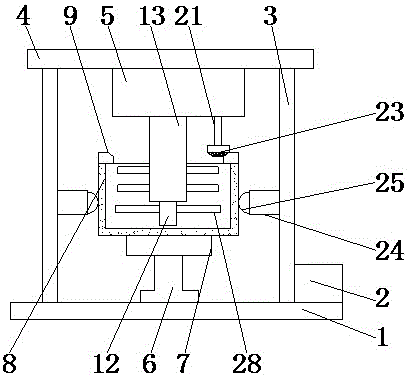

Rectangular steel tube variable-cross-section steel core anti-buckling limiting energy dissipation supporting member assembled with bolt shaped like Chinese character 'tian'

InactiveCN103711216ALimited lateral movementReach the limit effectShock proofingChinese charactersMaterials science

The invention relates to a rectangular steel tube variable-cross-section steel core anti-buckling limiting energy dissipation supporting member assembled with a bolt shaped like a Chinese character 'tian', and belongs to the technical field of anti-buckling supporting. The anti-buckling limiting energy dissipation supporting member comprises a cross-shaped steel core and an outer limiting body, the cross-shaped steel core is located in the outer limiting body, and four spaces defined by the steel core and the outer limiting body are respectively filled with a light-gauge steel section concrete filled steel tube. The anti-buckling limiting energy dissipation supporting member is characterized in that the partial cross section of the steel core becomes large, a limiting groove (3) is formed in the position, corresponding to a partial cross section largened section c, of the outer limiting body, the groove length of the limiting groove (3) is slightly larger than the section length of the corresponding partial cross section largened section, and the portion, located on a partial cross section largened section b, of the cross-shaped steel core outwards extends out of the outer limiting body through a corresponding limiting groove. After the steel core is deformed and buckled, an outer limiting steel tube and the axial stiffness of the buckled steel core are used for limiting the whole displacement of the structure to achieve the limiting target.

Owner:BEIJING UNIV OF TECH

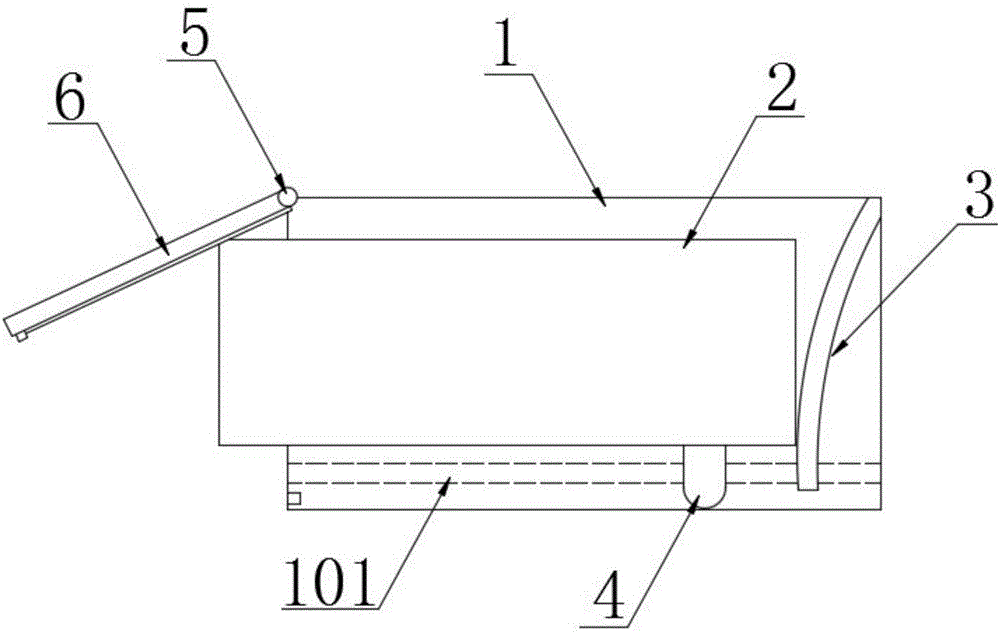

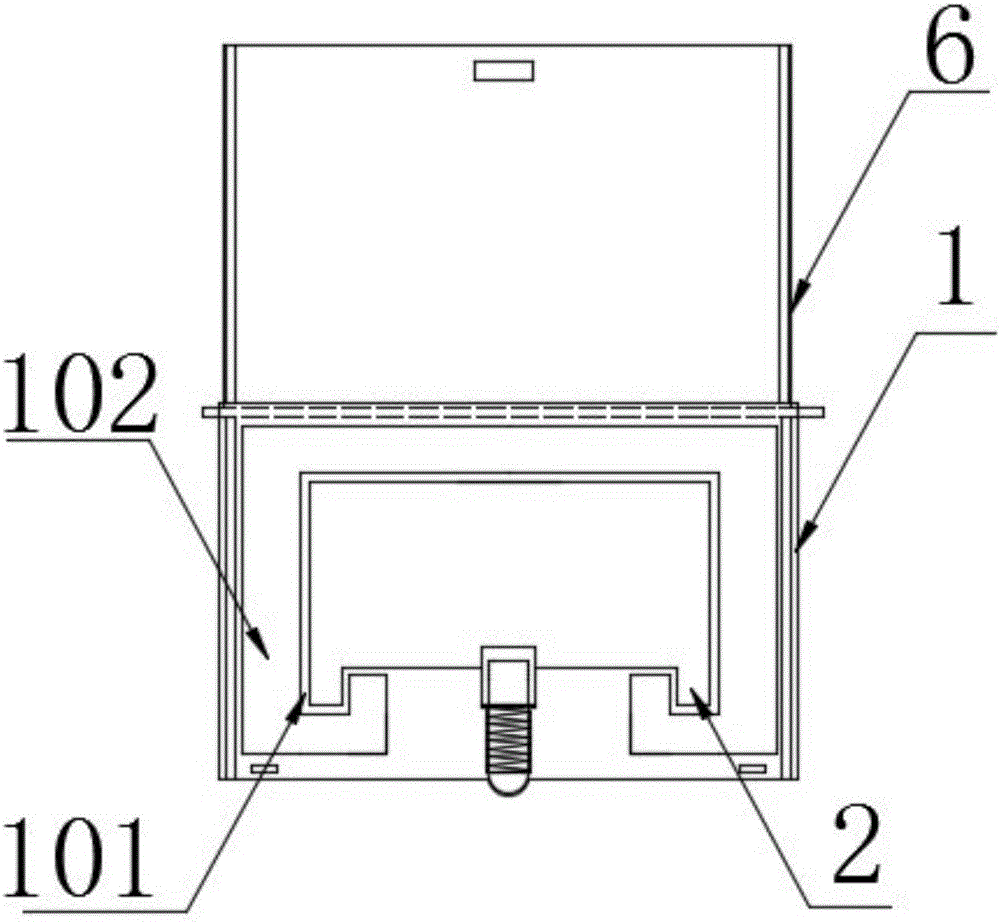

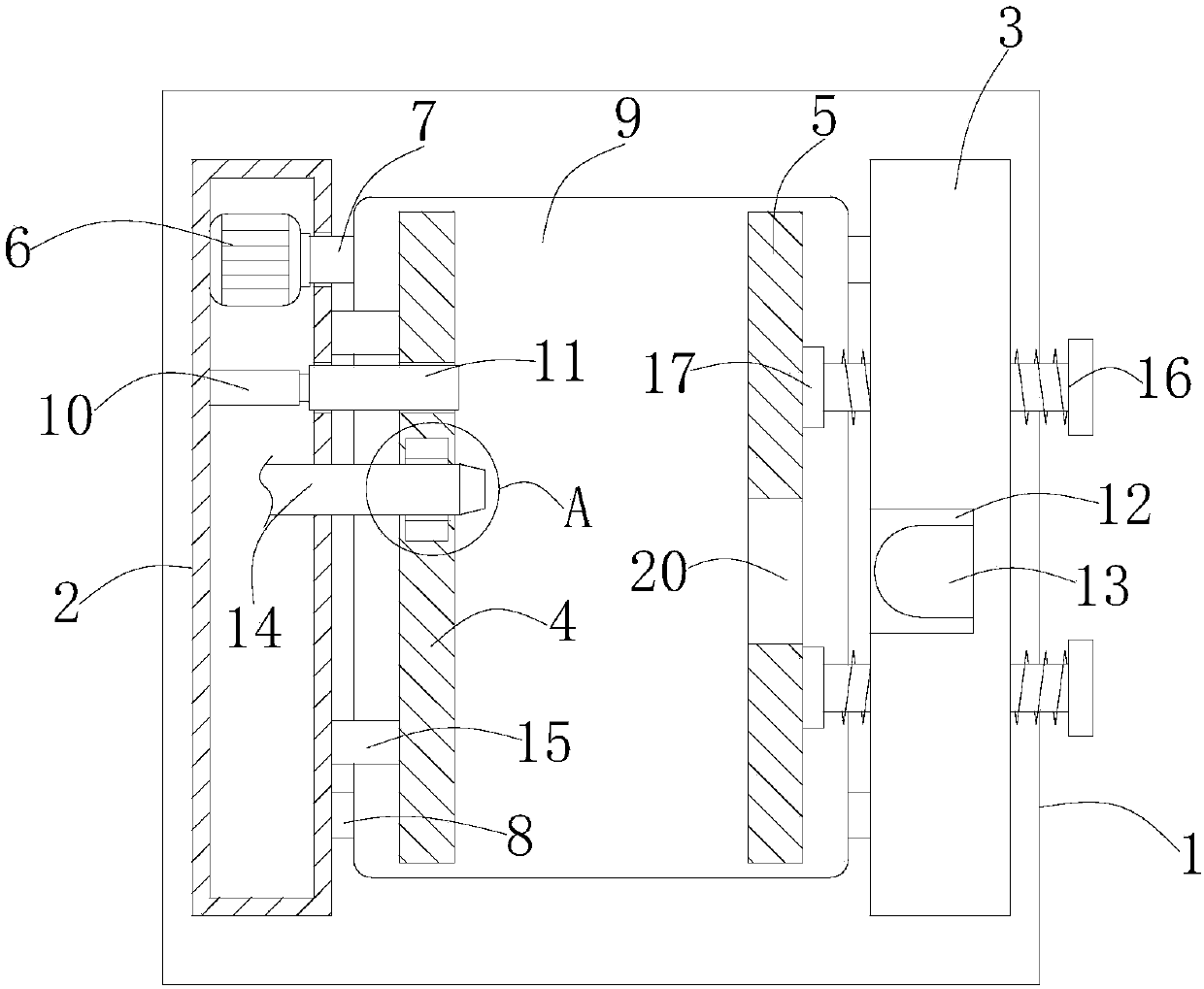

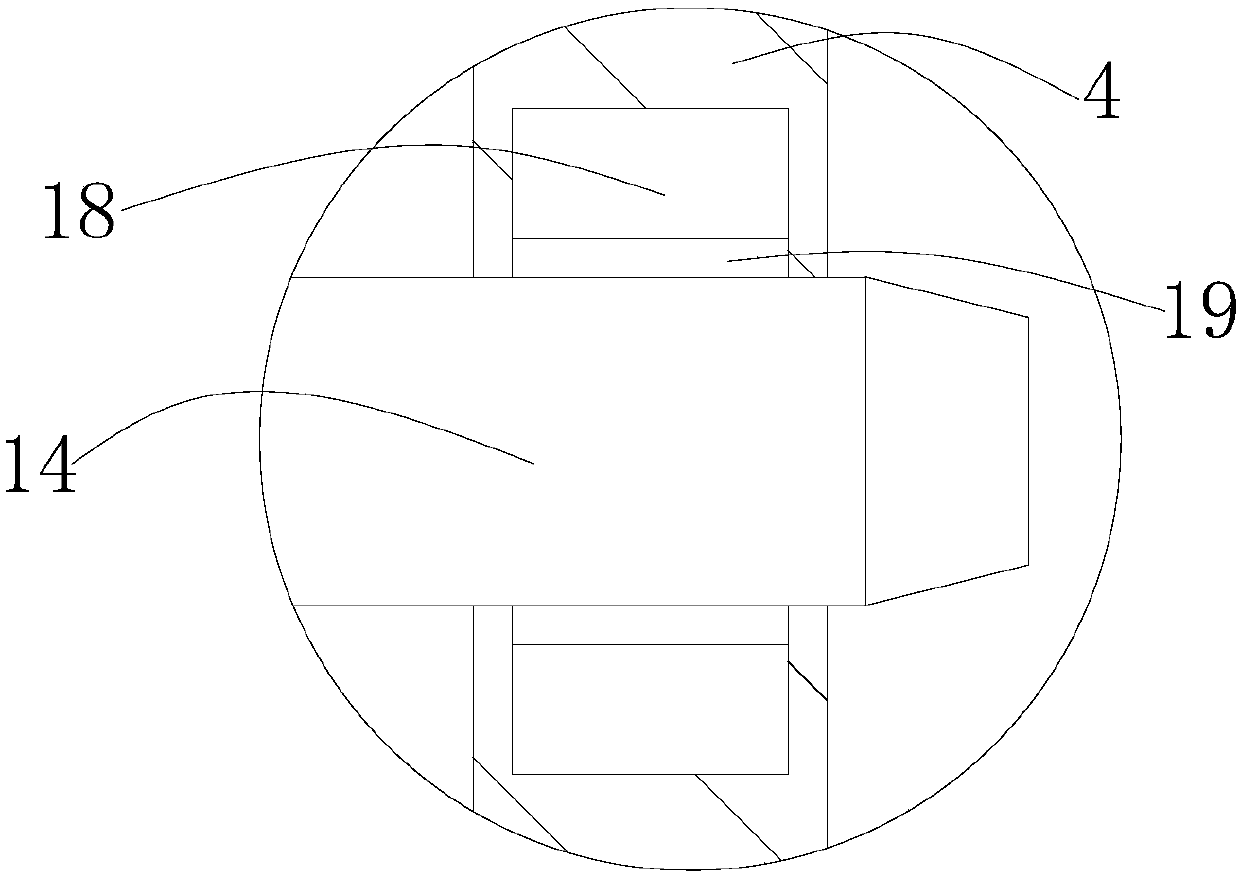

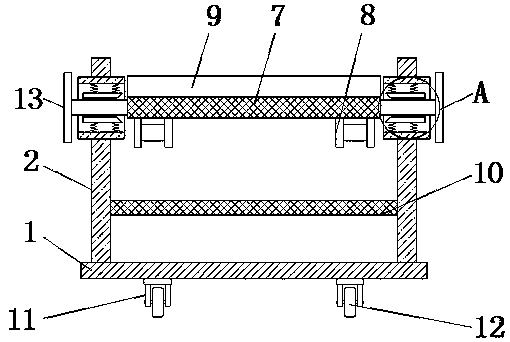

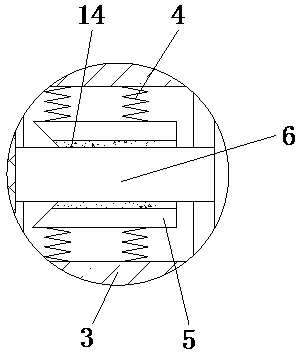

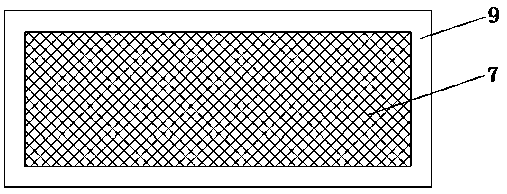

Drawable computer hardware interface with dustproof cover

PendingCN106325393AReach the limit effectReduce entryDigital data processing detailsComputer engineering

The invention relates to the technical field of computer accessories and particularly relates to a drawable computer hardware interface with a dustproof cover. The drawable computer hardware interface comprises a computer shell, wherein a hardware interface shell is mounted in an inner cavity of the computer shell; a built-in sliding accessory is attached on the inner wall of the computer shell; a limit component is mounted at the center of the bottom of the hardware interface shell; the dustproof cover is arranged away from a first spring part on the outer side of the computer shell and is mutually articulated with the computer shell via a rotating shaft. The design of the drawable computer hardware interface with the dustproof cover is capable of effectively preventing dust entering the hardware interface; the hardware interface shell can be extremely and conveniently cleaned even if the dust enters the hardware interface shell.

Owner:CHENGDU SIMAIER TECH

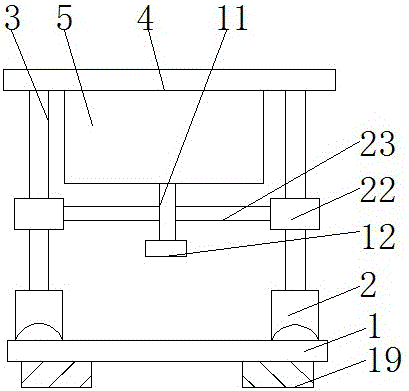

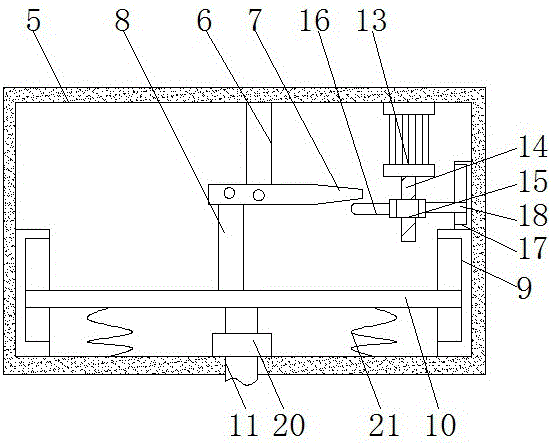

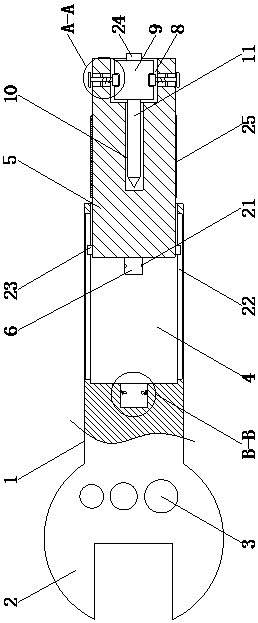

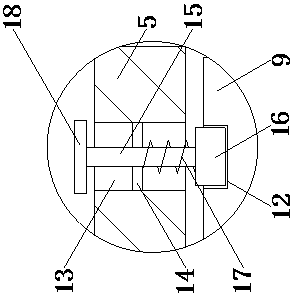

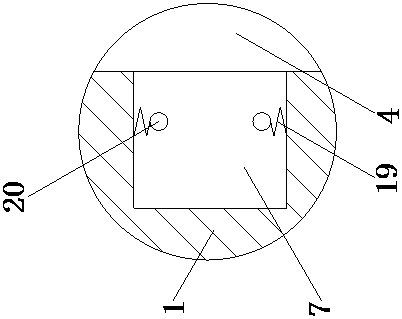

Forged piece manipulator

PendingCN108500974AEliminate bruisesReduce scrap rateProgramme-controlled manipulatorGripping headsElectric machineryManipulator

The invention discloses a forged piece manipulator. The forged piece manipulator comprises a supporting rod. A lifting platform is fixedly connected to the top of the right side of the supporting rod.An electric telescopic rod is fixedly connected to the right side of the lifting plate. The top of the lifting plate is fixedly connected with a motor. The output end of the motor penetrates throughthe lifting plate to extend to the bottom of the lifting plate. The output end of the motor is fixedly connected with a threaded rod. Through arrangement of the motor, the threaded rod, a first threadsleeve, rotary shaft blocks, first connecting rods, a second thread sleeve, second connecting rods and grippers, the forged piece manipulator achieves the effects that a forged piece can be clamped firmly and reliably, the surface quality defects such as impact damage caused by instable clamping of the forged piece are eliminated, and the rejection rate is reduced; accordingly, the problems thata commonly-used clamp only has two fulcrums to make contact with the forged piece and cannot clamp the forged piece unstably, the surface of the forced piece is damaged badly in the transferring process, the labor intensity of workers is large, and the working efficiency is low are solved.

Owner:常州江南万利机械配件有限公司

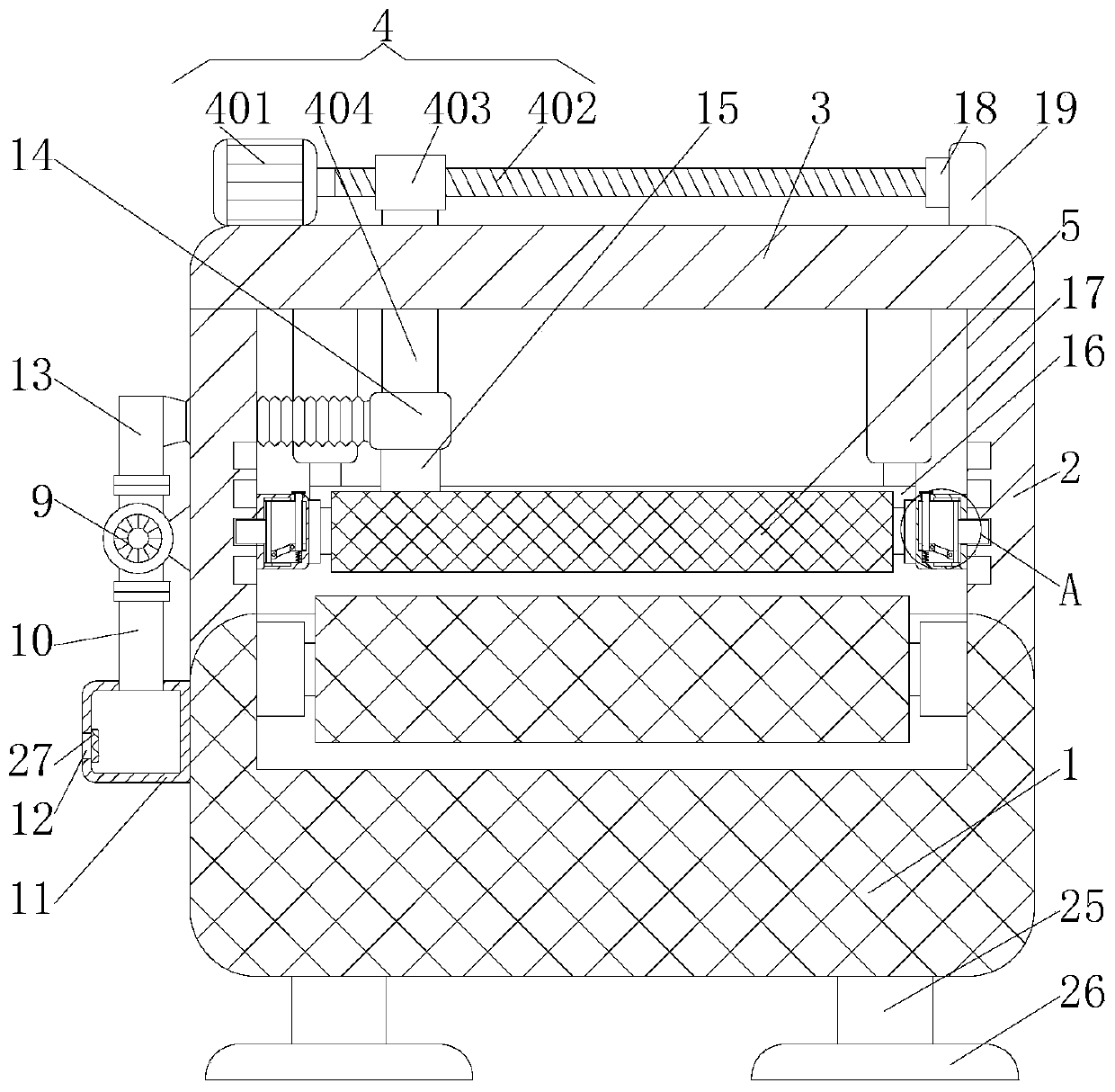

Outdoor hanging type electric cabinet for buildings

InactiveCN107568958AAchieve the effect of rotationAchieve a fixed effectLighting and heating apparatusFurniture partsDrive wheelSoftware engineering

The invention discloses an outdoor hanging type electric cabinet for buildings. The outdoor hanging type electric cabinet comprises a first supporting plate, a second supporting plate is fixedly connected to the left top of the first supporting plate, first fixing plates are fixedly connected to front end and rear end of a top axis position of the second supporting plate, a second fixing plate isfixedly connected to the axis position of the right side of the first supporting plate, a placement box is arranged at bottom of the second supporting plate, and a motor is fixedly connected to the back of an inner cavity of the second fixing plate. By arrangement of a motor, a driving wheel is driven to rotate; by the driving wheel, a driven wheel and a pull rope, the placement box is driven to move; by the placement box, article placement is realized; by electric telescopic rods, first connecting rods are driven to move; by clamping blocks and clamping grooves, fixing of the placement box isrealized. The electric cabinet is convenient for a user to place more articles, so that space saving is realized.

Owner:FOSHAN ZHIDA SIJIA ELECTRICAL & MECHANICAL TECH CO LTD

Clothes storage box

InactiveCN109330322AEasy to carryTo achieve the effect of hot airApparel holdersKitchen equipmentEngineeringAir cavity

The invention relates to the technical field of articles for life, and discloses a clothes storage box. The clothes storage box comprises a storage box body, a box cover is hinged to the top of the storage box body, a portable handle is fixedly mounted on the top of the box cover, a rotary fan is fixedly mounted on the inner bottom wall of the storage box body, a heating resistor is fixedly mounted on the top of the rotary fan, air ducts fixedly connected with an air cavity are formed in the left side and the right side of the inner wall of the storage box body, and limiting plates are fixedlymounted on the opposite sides of the two air ducts. According to the clothes storage box, the box cover is mounted on the storage box body, the effect of sealing the storage box is achieved, the portable handle is mounted on the box cover, the effect of conveniently carrying the storage box is achieved, the rotary fan is mounted on the storage box body, the heating resistor is mounted on the topof the rotary fan, and the effect that hot air is formed in the storage box through the air ducts is achieved.

Owner:应城御尚智能家居设计有限公司

Portable EV battery mounting seat

ActiveCN110165095AEasy to moveSolve the inconvenienceElectric propulsion mountingCell component detailsAutomotive batteryEngineering

The invention discloses a portable EV battery mounting seat. The portable EV battery mounting seat comprises a mounting seat body and a bottom plate, the front surface of the bottom plate is fixedly connected with the back surface of the mounting seat body, the top portion and the bottom portion of the inner wall of the mounting seat body are fixedly connected with rubber pads, the back surface ofthe inner wall of the mounting seat body is fixedly connected with a sponge block, the upper surface and the lower surface of the mounting seat body are both fixedly connected with fixing plates, theleft side of the bottom plate is provided with a groove, the right side of the inner wall of the groove is provided with two circular holes, the inner walls of the two circular holes are movably connected with circular rods, the surfaces of the circular rods are provide with slots, and one ends, far away from the bottom plate, of the two circular rods are fixedly connected with the right side ofa handle. Through arrangement of the bottom plate, the circular rods, plug pins, square rods, pulleys and support rods, the problem that the electric automobile is inconvenient to produce due to the fact that the battery mounting seat of the electric automobile is large in size and not easy to move is solved.

Owner:FUJIAN HUAXIANG POWER TECH

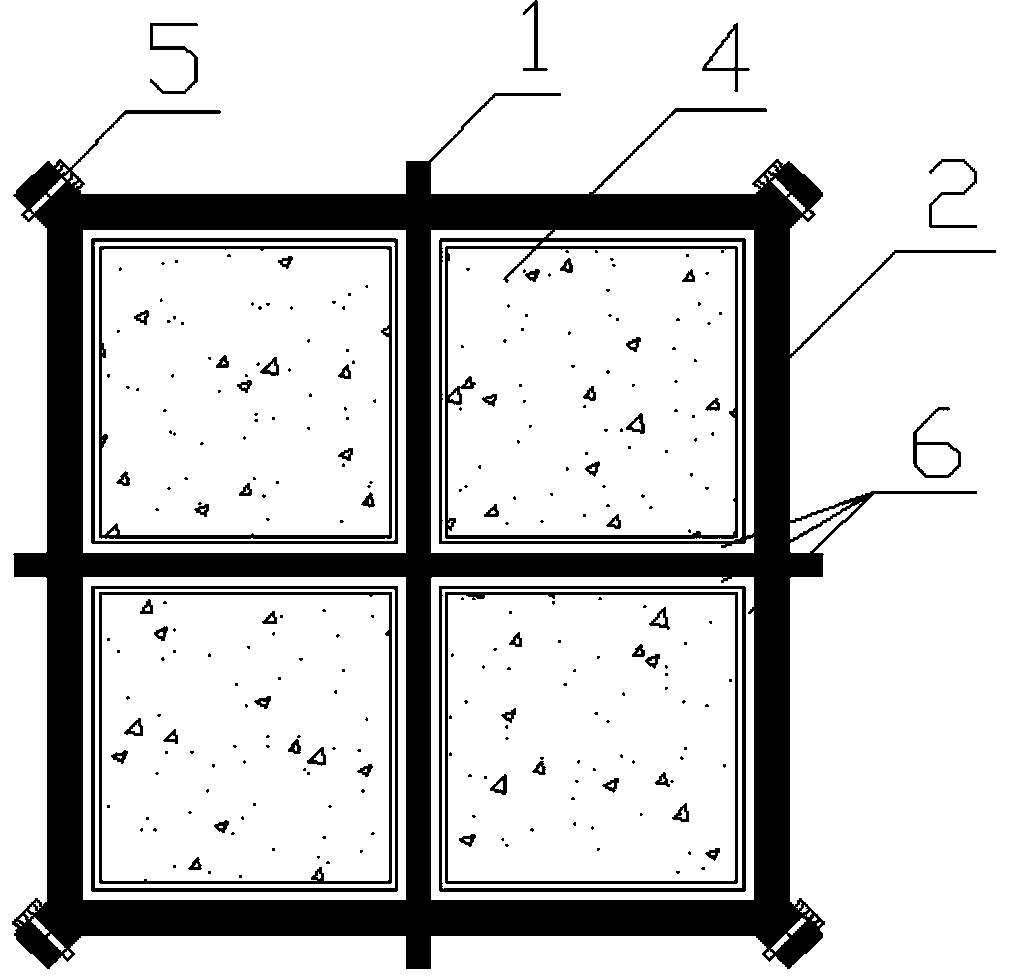

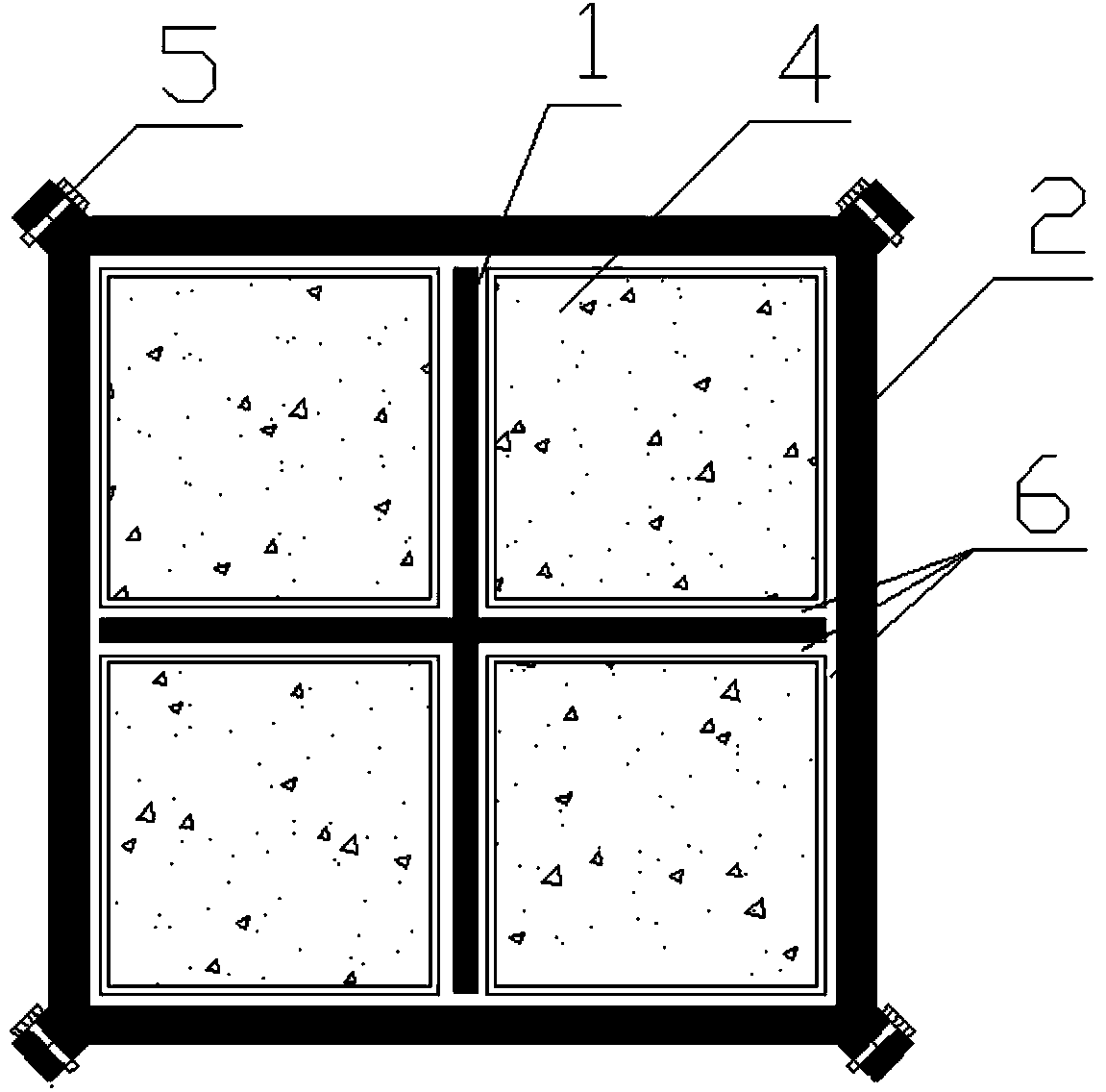

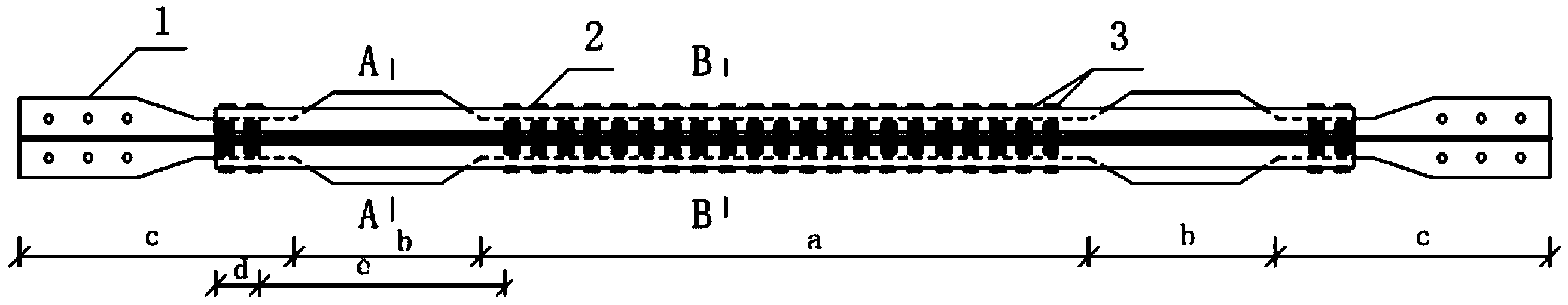

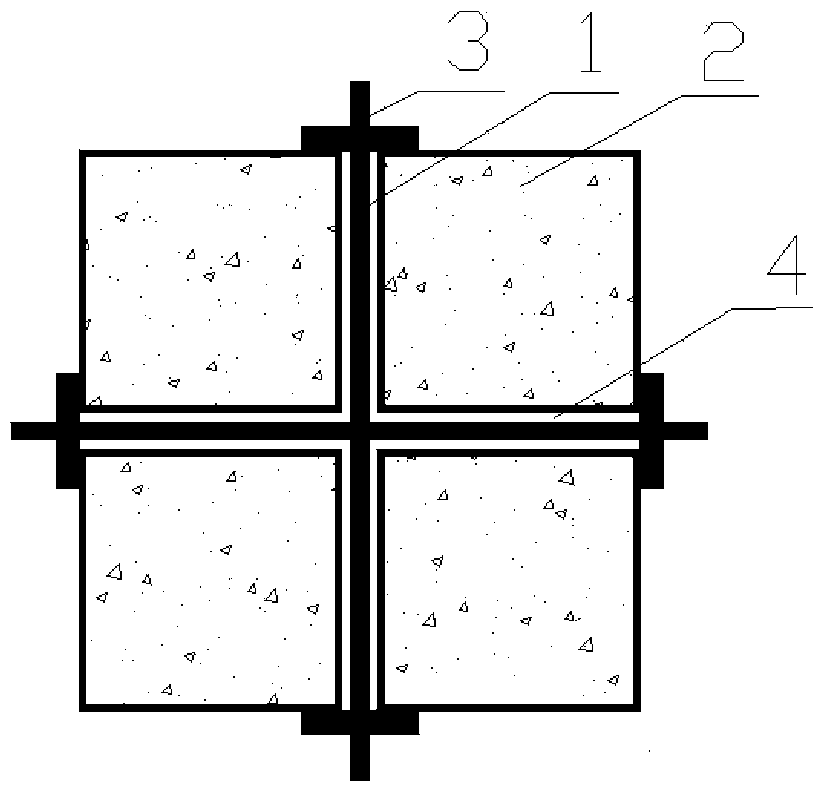

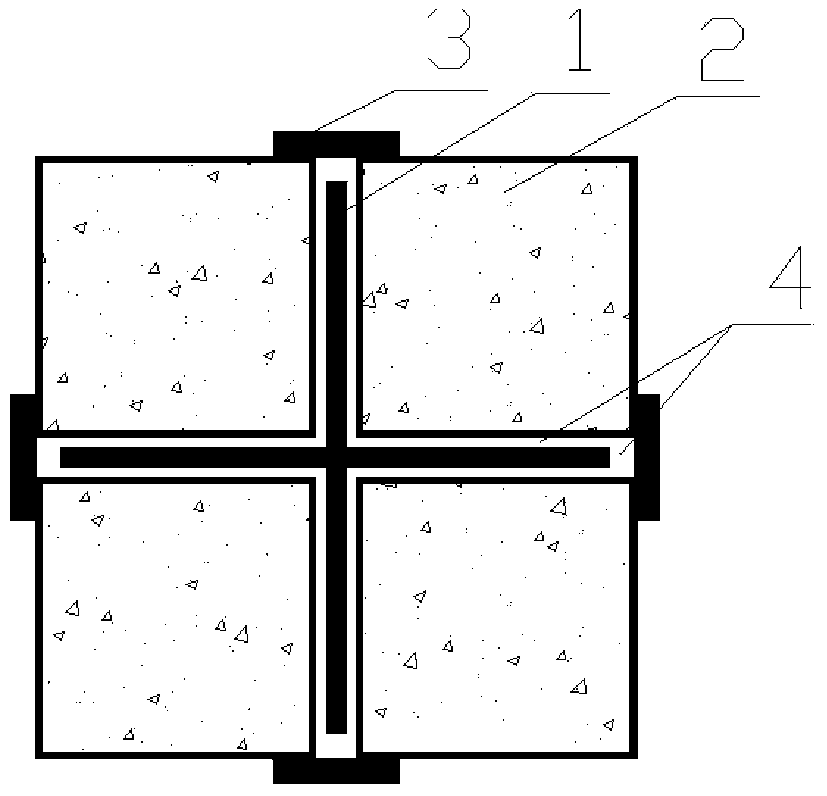

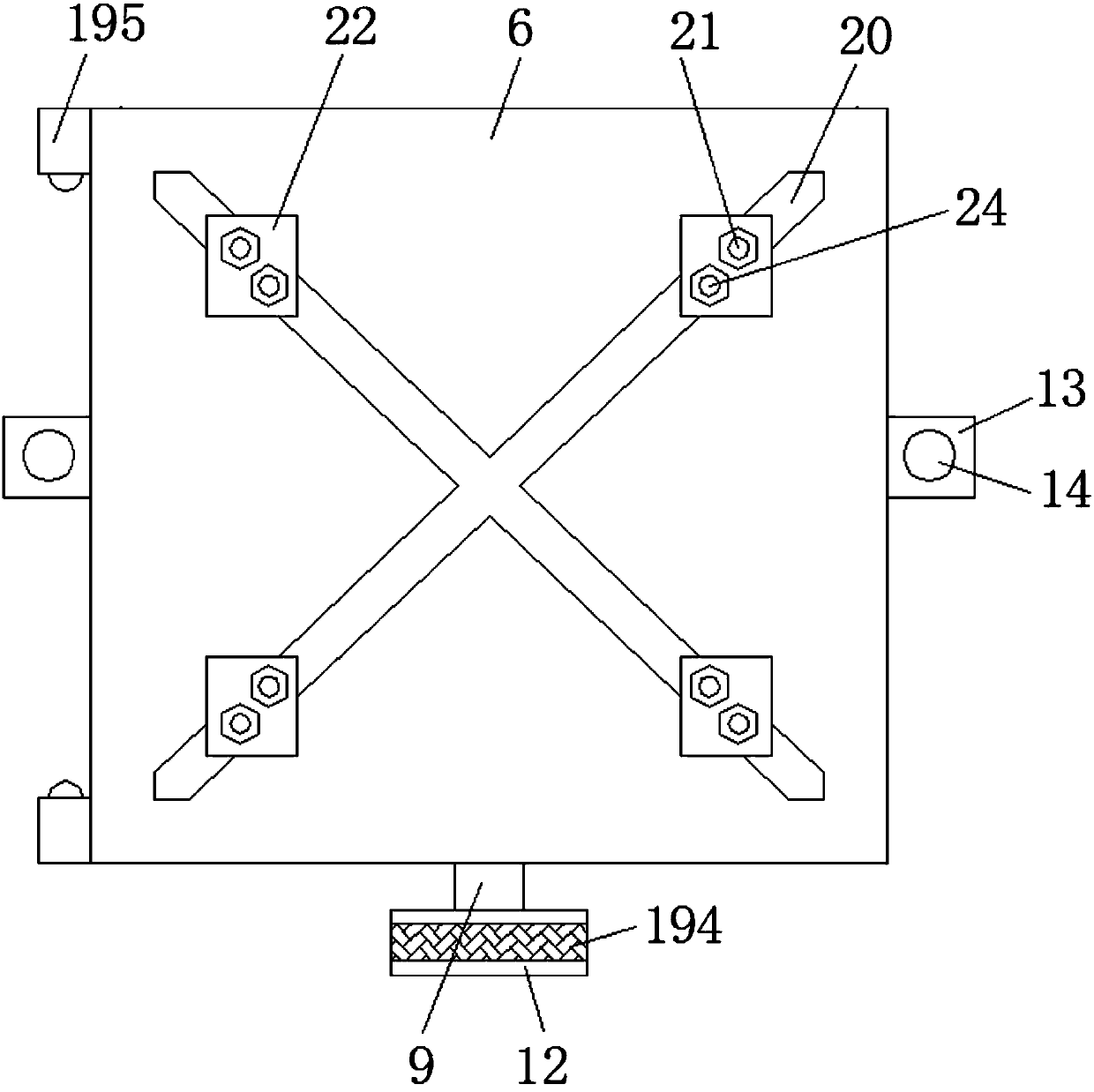

Four-steel-tube externally-attached decoration plate type cross-shaped variable-cross-section steel core energy dissipation limiting anti-buckling supporting member

InactiveCN103711224ALimited lateral movementReach the limit effectShock proofingSupporting systemChinese characters

The invention relates to a four-steel-tube externally-attached decoration plate type cross-shaped variable-cross-section steel core energy dissipation limiting anti-buckling supporting member, and belongs to the field of anti-buckling energy dissipation limiting supporting members. An outer limiting body is mainly formed by four square light-gauge steel section concrete filled steel tubes forming a shape shaped like a Chinese character 'tian', and the outer sides of the four square light-gauge steel section concrete filled steel tubes are limited by partially welding decoration plates; the welding decoration plates are not arranged on the short edge, corresponding to a cross section largened section b, of the outer limiting body, and the welding decoration plates are welded to the other edges. A steel core is located in a gap of a cross-shaped structure in the middles of the four square light-gauge steel section concrete filled steel tubes, the steel core comprises a buckling working section a, the cross section partial largened section b and a connecting section c, the position, where the decoration plates are not welded to an outer steel tube, of the cross section of the steel core is partially expanded with a 60-degree slope angle, the buckled steel core is in good connection with the outer limiting body, sliding dropping is prevented, and the limiting function is achieved through the axial stiffness of the outer limiting body. After the steel core is buckled, the axial stiffness of the outer limiting body serves as the auxiliary stiffness of a supporting system, and therefore the lateral displacement of the structure is easily limited.

Owner:BEIJING UNIV OF TECH

Car part storage box

InactiveCN106881698ATo achieve the effect of storageAchieve a fixed effectWork tools storageThreaded pipeSoftware engineering

The invention discloses a storage box for auto parts, comprising a box body, the bottom of the inner cavity of the box is fixedly connected with a first support plate, and the bottom of the inner cavity of the box is movably connected with a movable bottom at the bottom of the first support plate. One end of the movable box passes through the box and extends to the outside of the box, the top and the left side of the bottom of the movable box are fixedly connected with pulleys, and the inner wall of the box and the bottom of the first support plate are equipped with pulleys The first chute used with it. The present invention achieves the effect of storing parts by setting the movable box, achieves the effect of driving the second support plate to move through the threaded rod and the threaded tube, and achieves the effect of driving the first connecting rod to move through the second chute and the first slider The effect of fixing the first connecting rod is achieved through the clamping slot and the clamping block, and the effect of fixing the components is achieved through the clamping plate. The components of different sizes can be fixed, which is convenient for users to use.

Owner:济源市万荣商贸有限公司

Metal polisher

InactiveCN106975993ATo achieve the mobile effectTo achieve the storage effectEdge grinding machinesGrinding carriagesEngineeringMetal polisher

The invention discloses a metal grinding machine, comprising a base, a support plate is fixedly connected to both sides of the top of the base, a cylinder is fixedly connected to one side of the support plate, and a cylinder is fixedly connected to an end far away from the support plate. The first splint, the bottom of the first splint is provided with a long hole, the inside of the long hole is provided with a second splint, the side of the second splint close to the cylinder is provided with a slot, the bottom of the surface of the first splint and There is a first groove on the side close to the cylinder; the invention achieves the effect of driving the movement of the first splint by setting the cylinder, the effect of storing the second splint through the long hole, and the effect of fixing the clamping block through the spring , through the block and slot, the effect of fixing the second splint can be achieved, and the effect of increasing the area of the splint can be achieved through the first splint and the second splint, which can clamp metals of different sizes, which is convenient for users to adjust the splint of different sizes. metal for grinding.

Owner:长兴达程科技有限公司

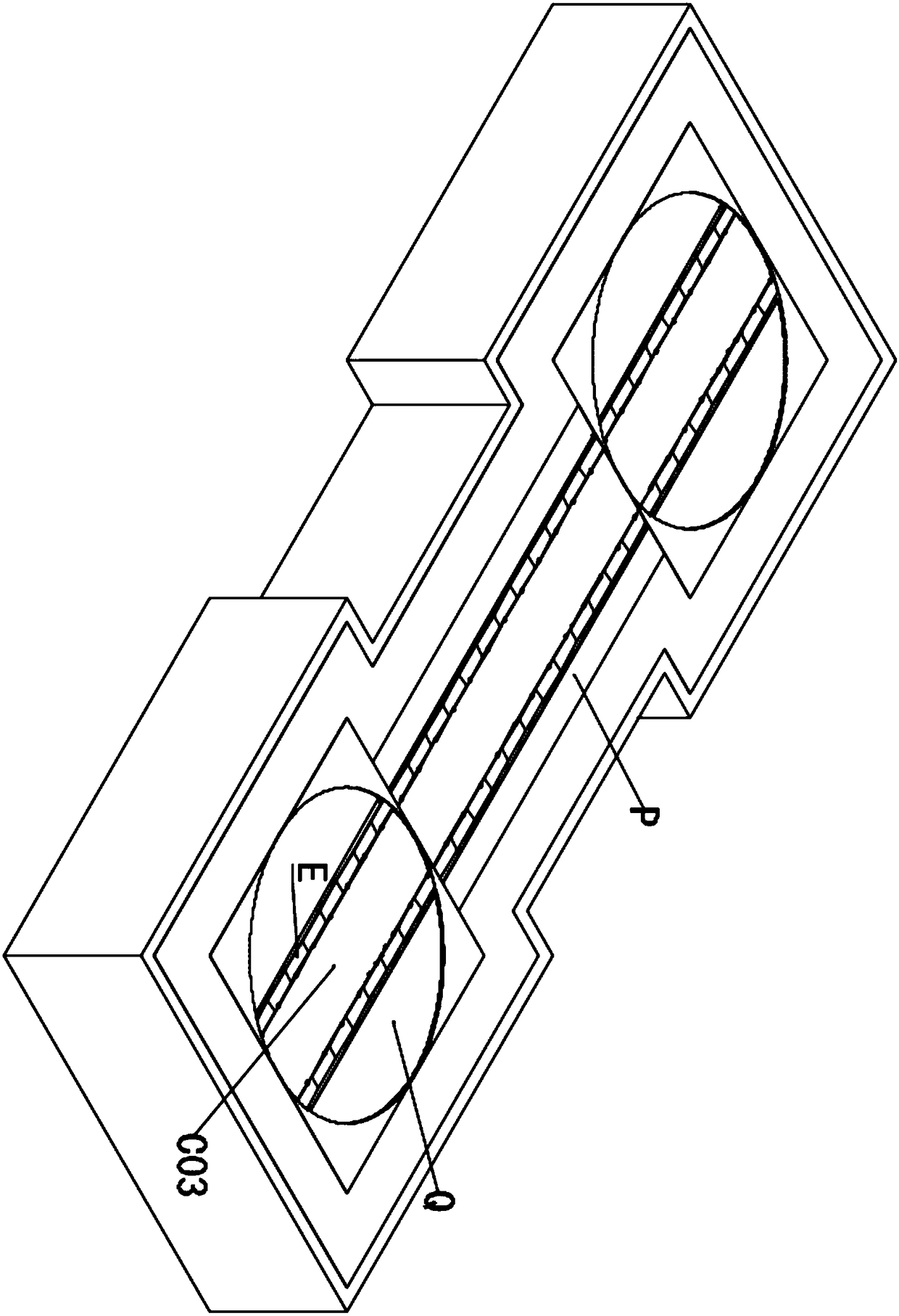

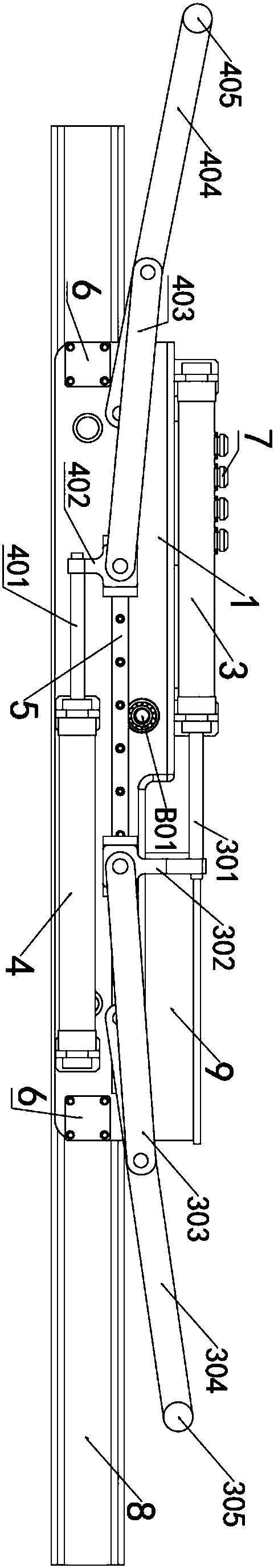

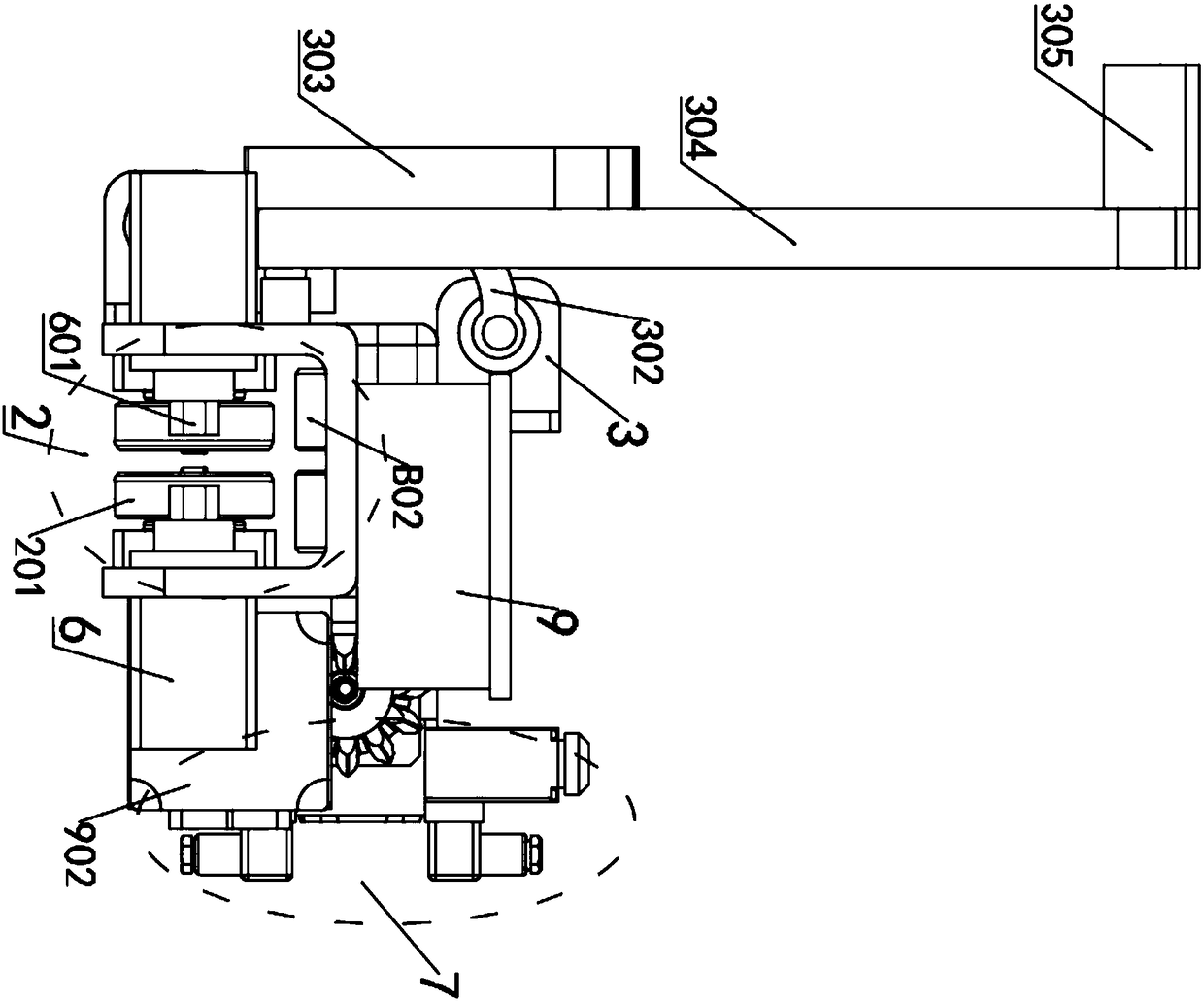

Transfer system for transporting bogies

The invention discloses a transfer system for transporting bogies, and relates to the technical field of bogie transporting devices. The problem that in the existing bogie maintenance process, the bogie transporting efficiency is low is solved. The transfer system comprises rotary tables and straight rails. First rails used for transporting the bogies are arranged on the rotary tables and the straight rails. Transporting rails used in cooperation with the first rails are arranged on one sides of the first rails. Vehicle bodies used for pushing the bogies are mounted on the transporting rails.The transfer system has the advantages of being high in transporting efficiency and simple in operation and saving energy.

Owner:成都岁生科技有限责任公司

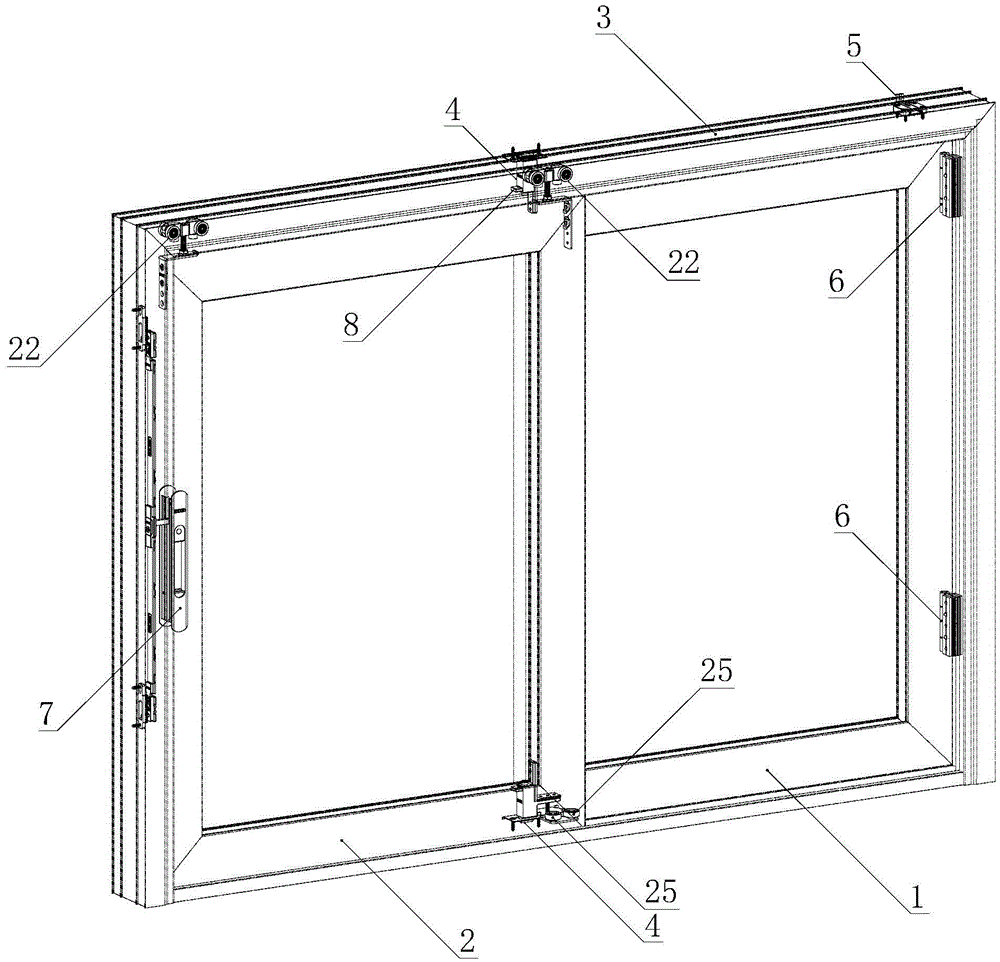

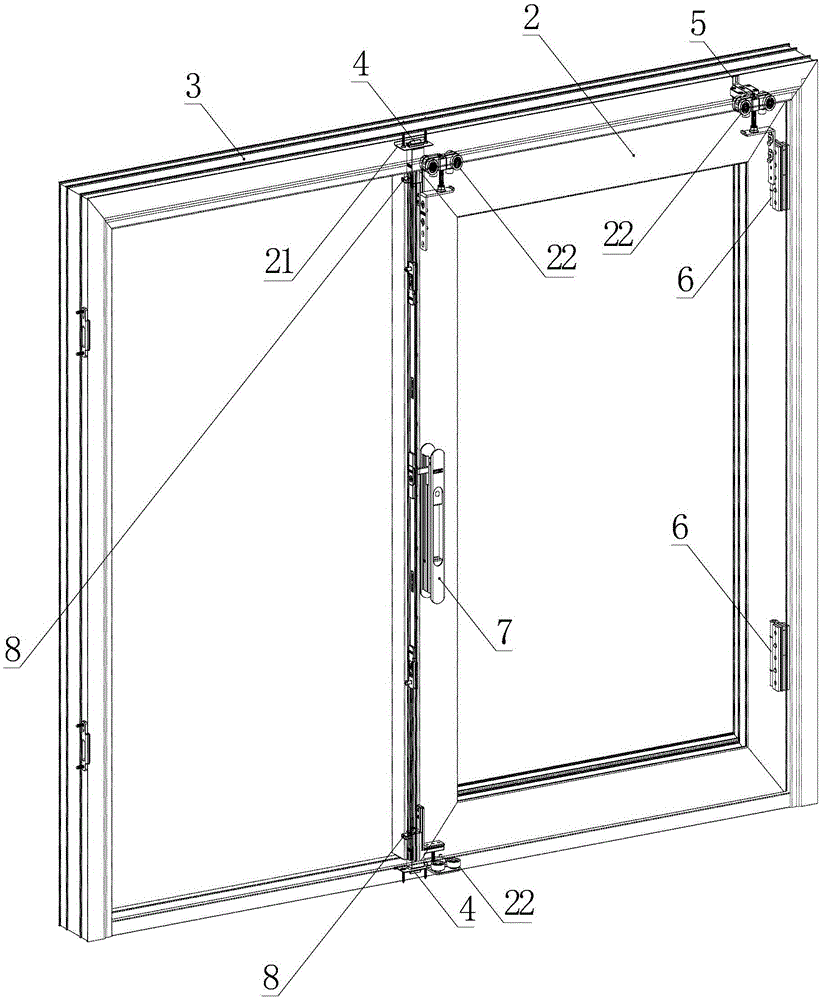

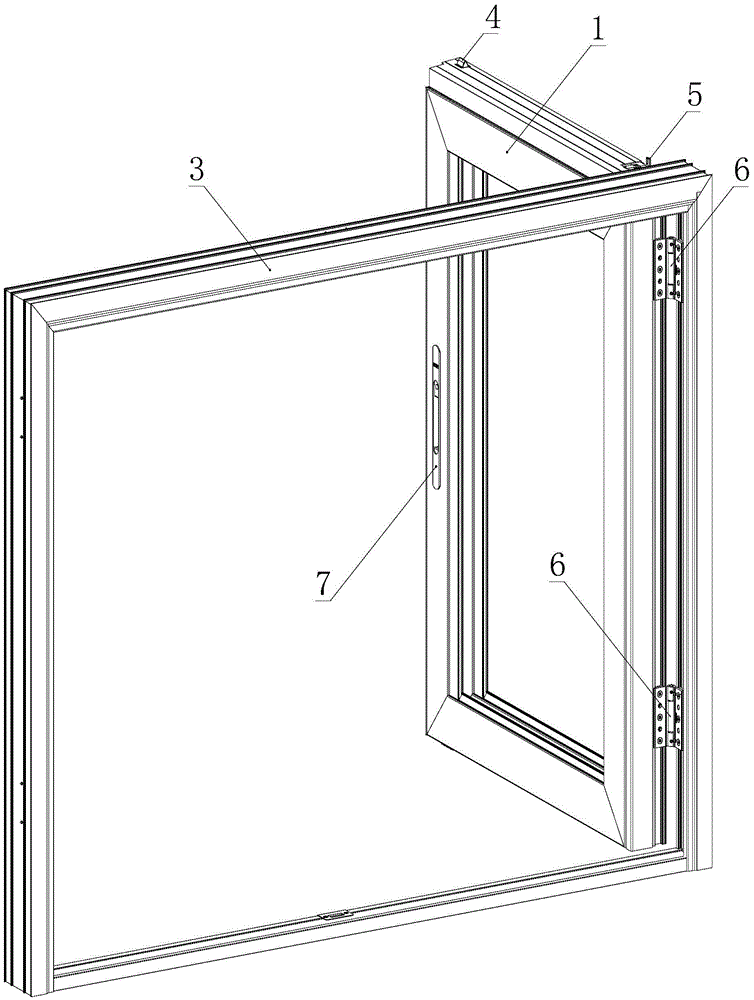

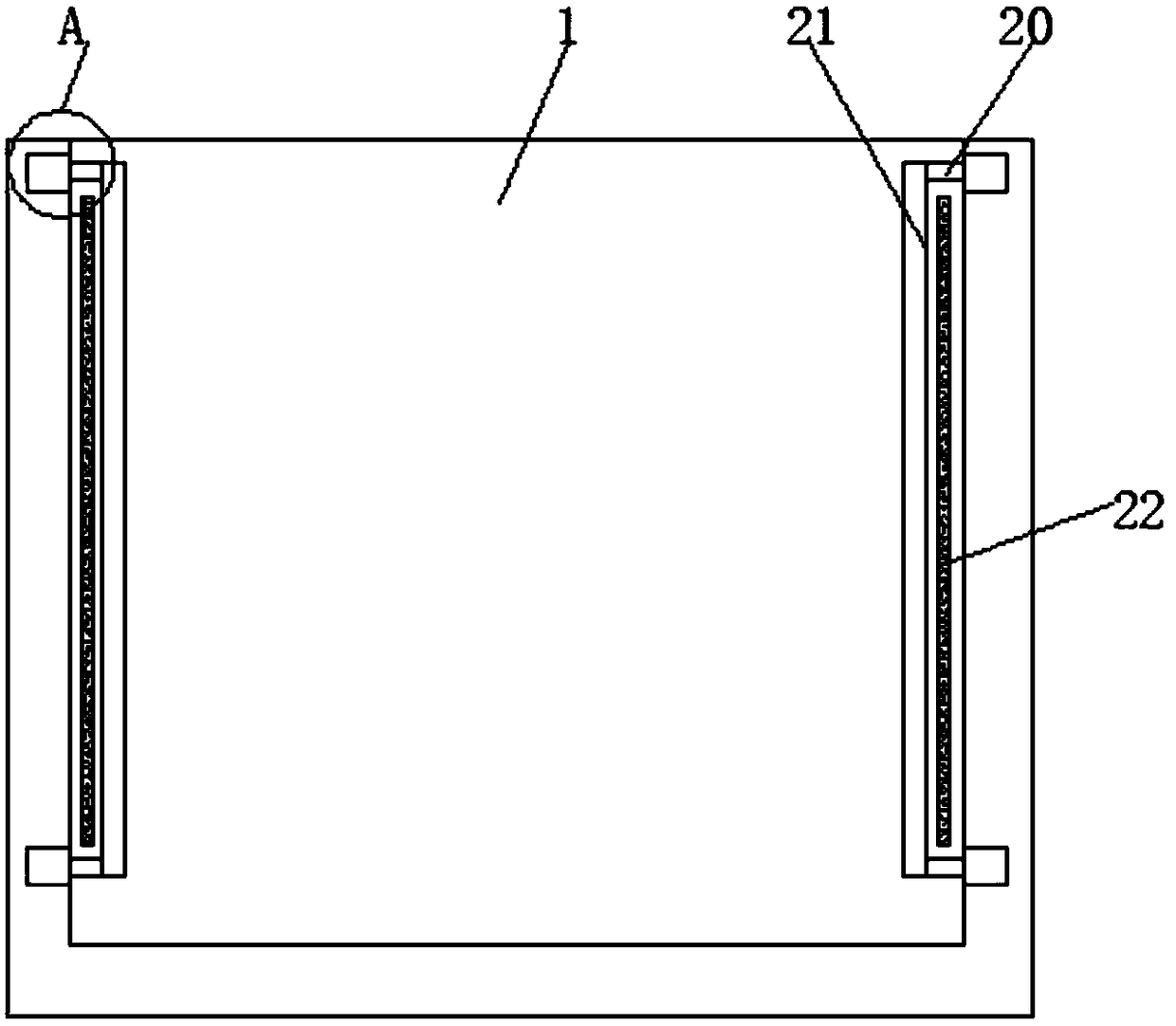

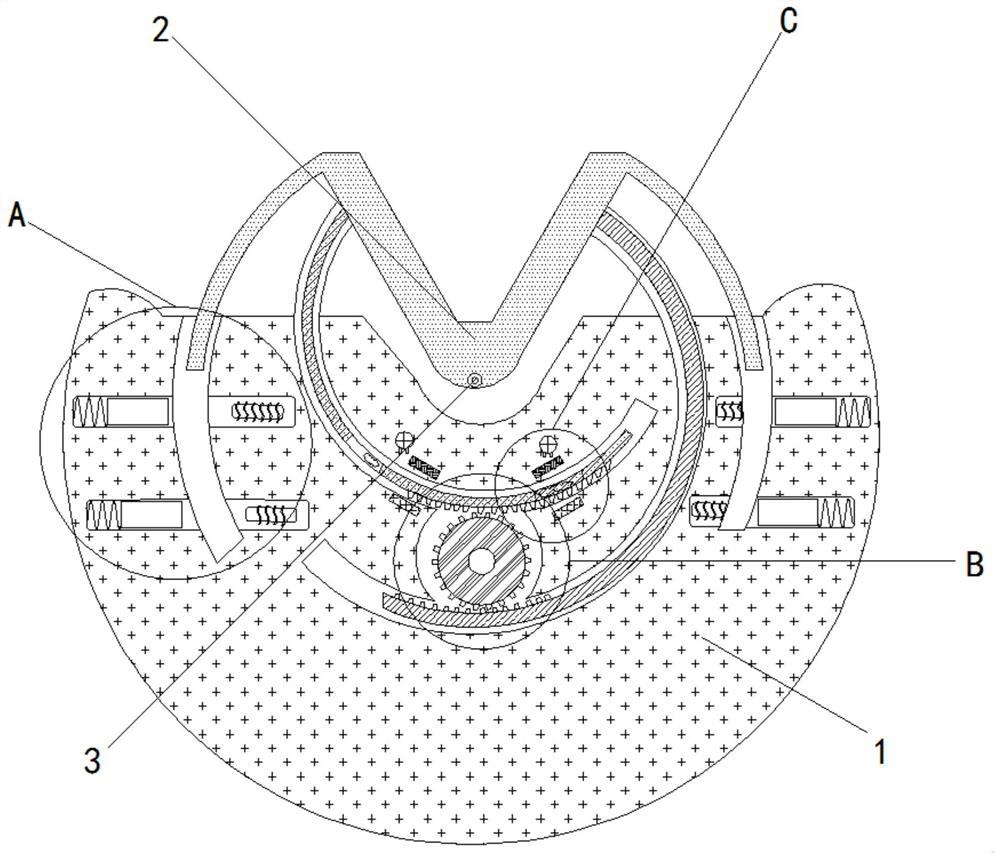

Automatic positioning lock and anti-misoperation sliding casement door and window hardware system and method

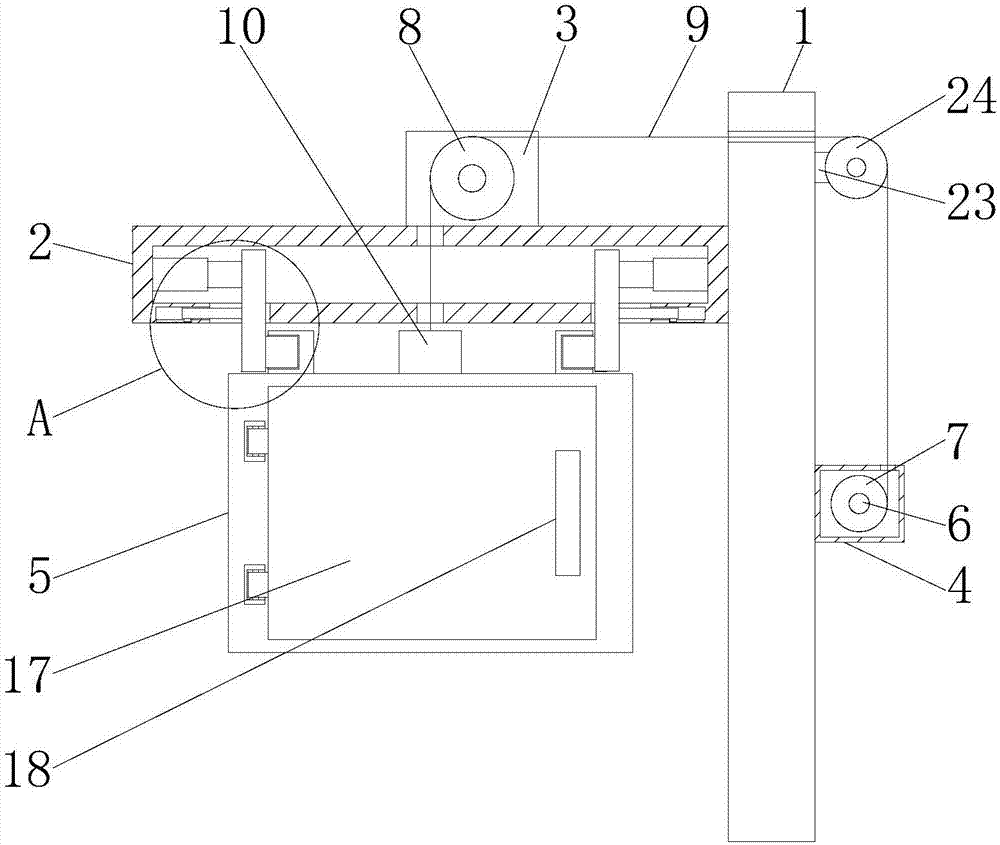

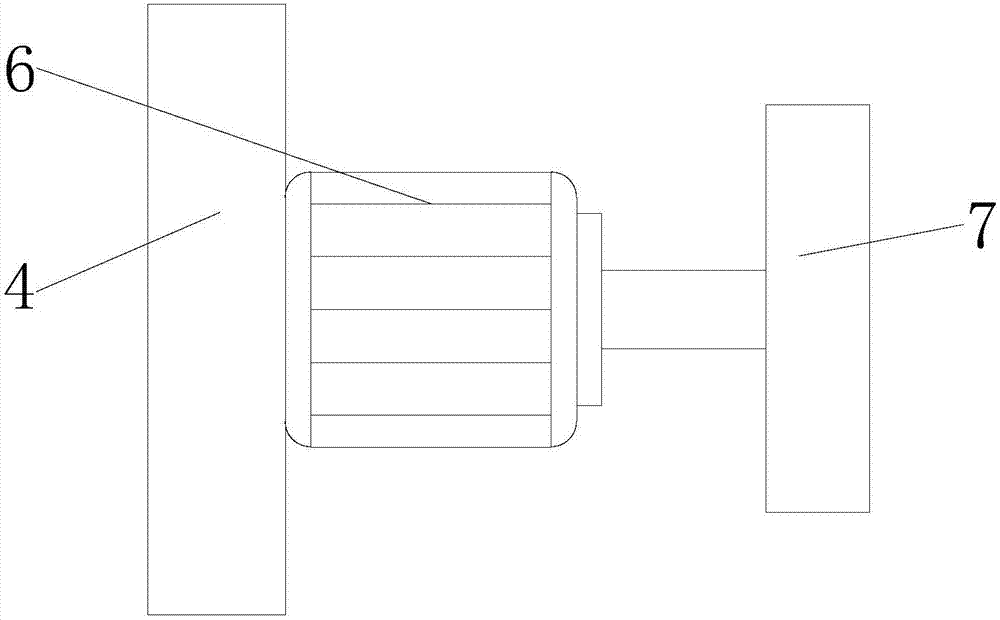

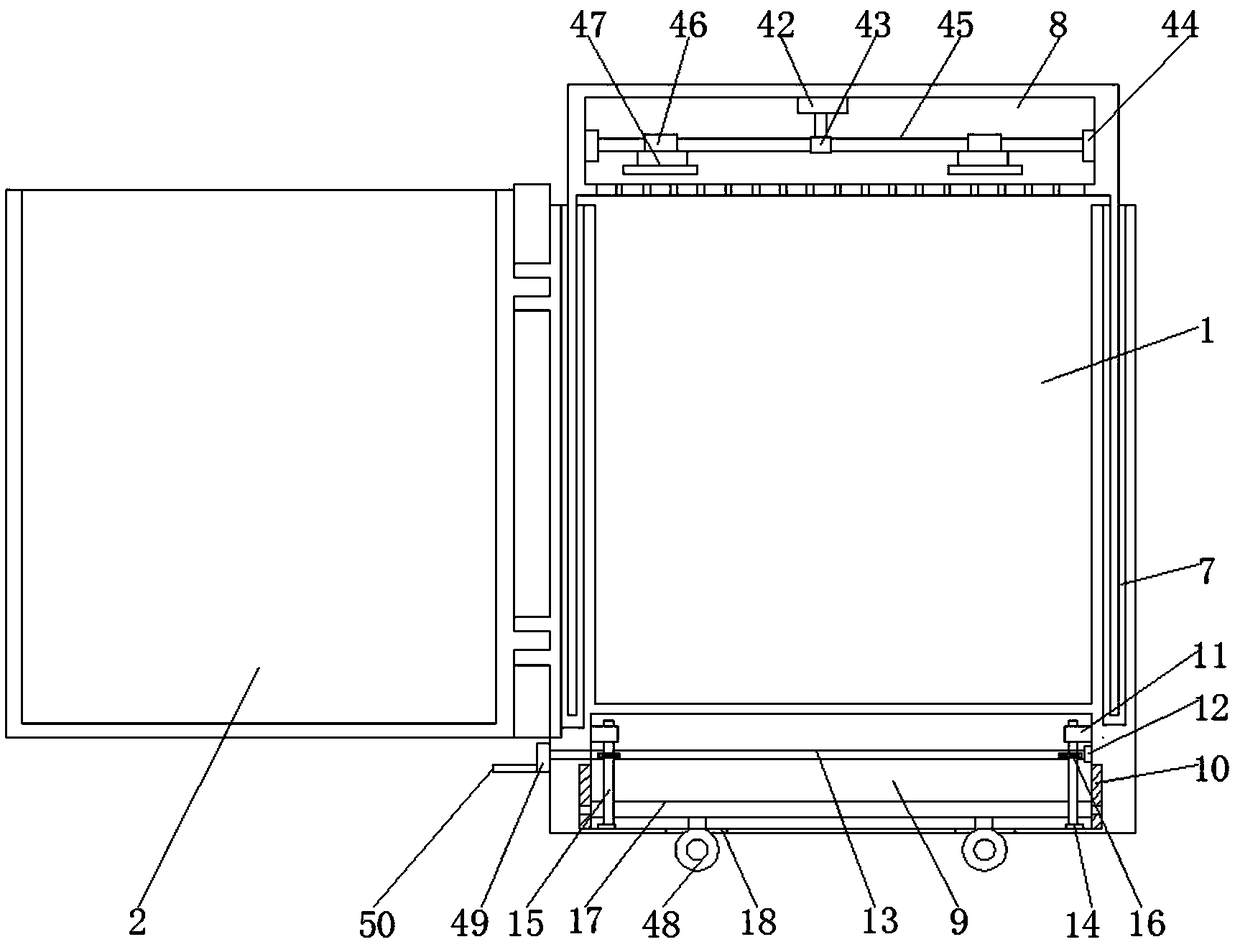

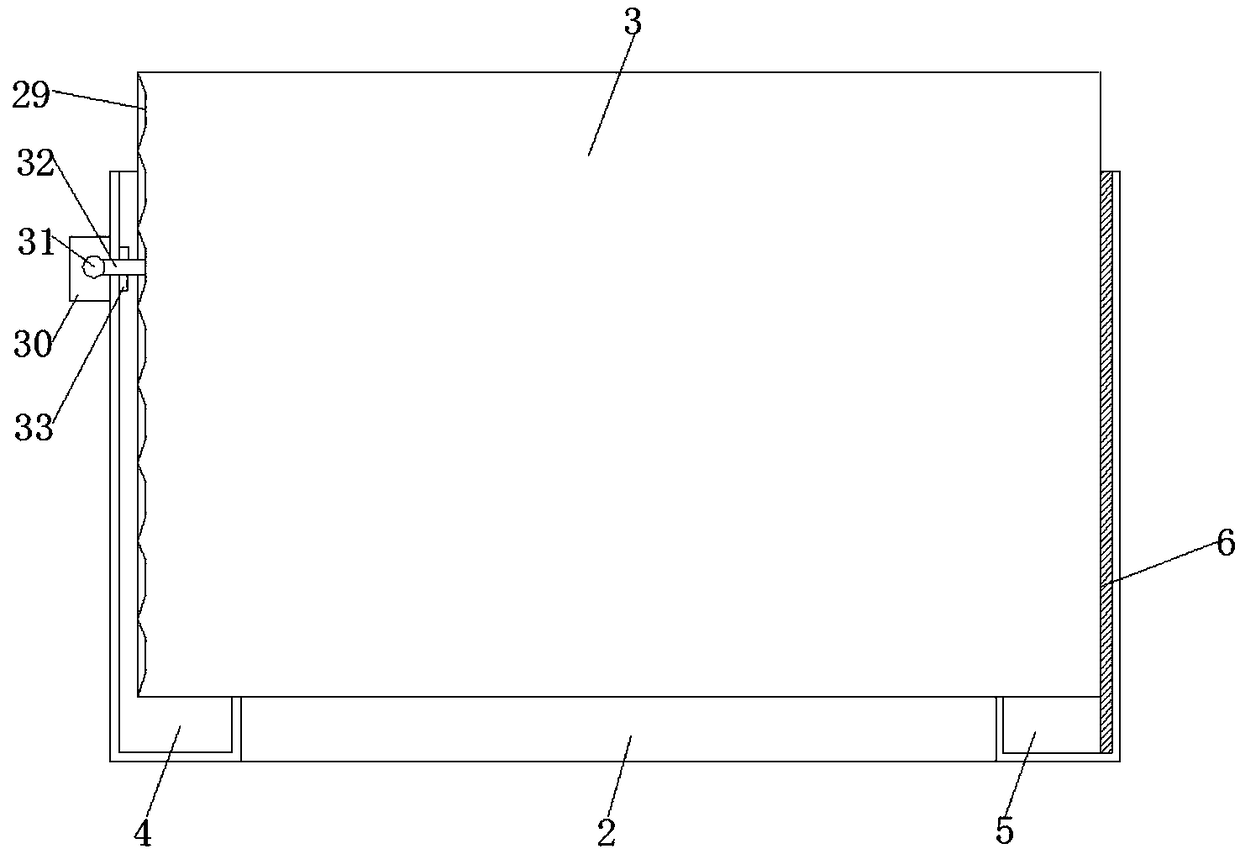

ActiveCN105604393AAvoid misuseEasy to useBuilding locksWing arrangementsSash windowElectrical and Electronics engineering

The invention discloses an automatic positioning lock and anti-misoperation sliding casement door and window hardware system and method. The system comprises a casement door and window sash, a siding door and window sash, a door and window frame, an anti-misoperation automatic lock device and an anti-misoperation limiting device. The casement door and window sash is arranged in the door and window frame through hinges. The sliding door and window sash is arranged in the door and window frame in a sliding mode. The sliding door and window sash has an original locking position and an overlapping position, at the original locking position, the sliding door and window sash slides on the door and window frame, and at the overlapping position, the sliding door and window sash slides on the casement door and window sash. When the sliding door and window sash is at the overlapping position, the casement door and window sash can drive the sliding door and window sash to be opened outwards through the hinges. The casement door and window sash and the door and window frame are automatically locked and / or automatically unlocked through the anti-misoperation automatic lock device. When the casement door and window sash is at the overlapping position, the sliding door and window sash and the casement door and window sash can be automatically limited and / or automatically unlimited through the anti-misoperation limiting device.

Owner:佛山凯森贝格建筑五金有限公司

Control valve with flow limiting function

InactiveCN106224576AGood current limiting effectImprove work efficiencyOperating means/releasing devices for valvesSlide valveEngineeringControl valves

The invention discloses a control valve with a flow limiting function. The control valve comprises a bottom plate. A valve seat and first supporting columns are sequentially arranged on the top of the bottom plate from left to right. A water outlet pipe and a water inlet pipe are clamped and connected to the two side faces of the valve seat correspondingly. Third supporting columns are fixedly connected to the two sides of the top of the valve seat. A sealing ring is arranged on the top of the valve seat. The tops of the third supporting columns are fixedly connected with a baffle. According to the control valve with the flow limiting function, the vertical movement of an adjusting valve is achieved through cooperative usage of connecting rods, a sliding rod, a motor, a gear and a gear rail, and therefore the flow limiting effect is achieved. The effect of connecting rod limiting is achieved through cooperative usage of a connecting plate, a limiting groove and a sliding block, and deflection cannot happen when the connecting rods drive a connecting beam to move up and down. The control valve is ideal in flow limiting effect, and the work efficiency is improved.

Owner:JOHNSTON FLOW TECH WUXI CO LTD

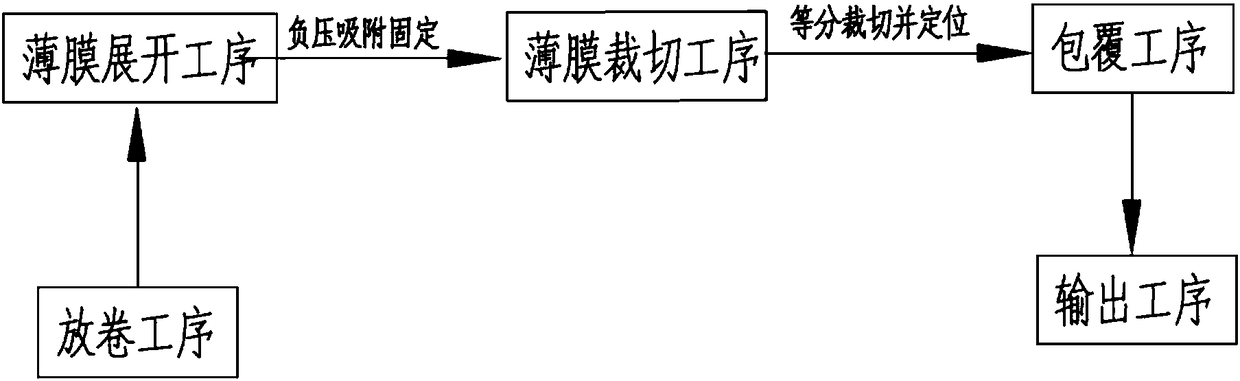

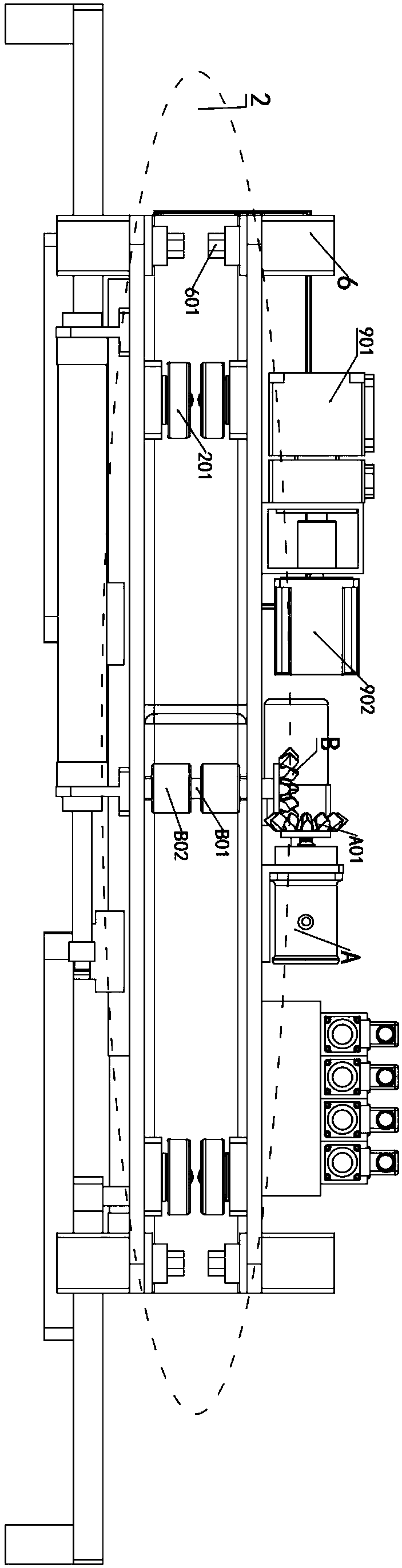

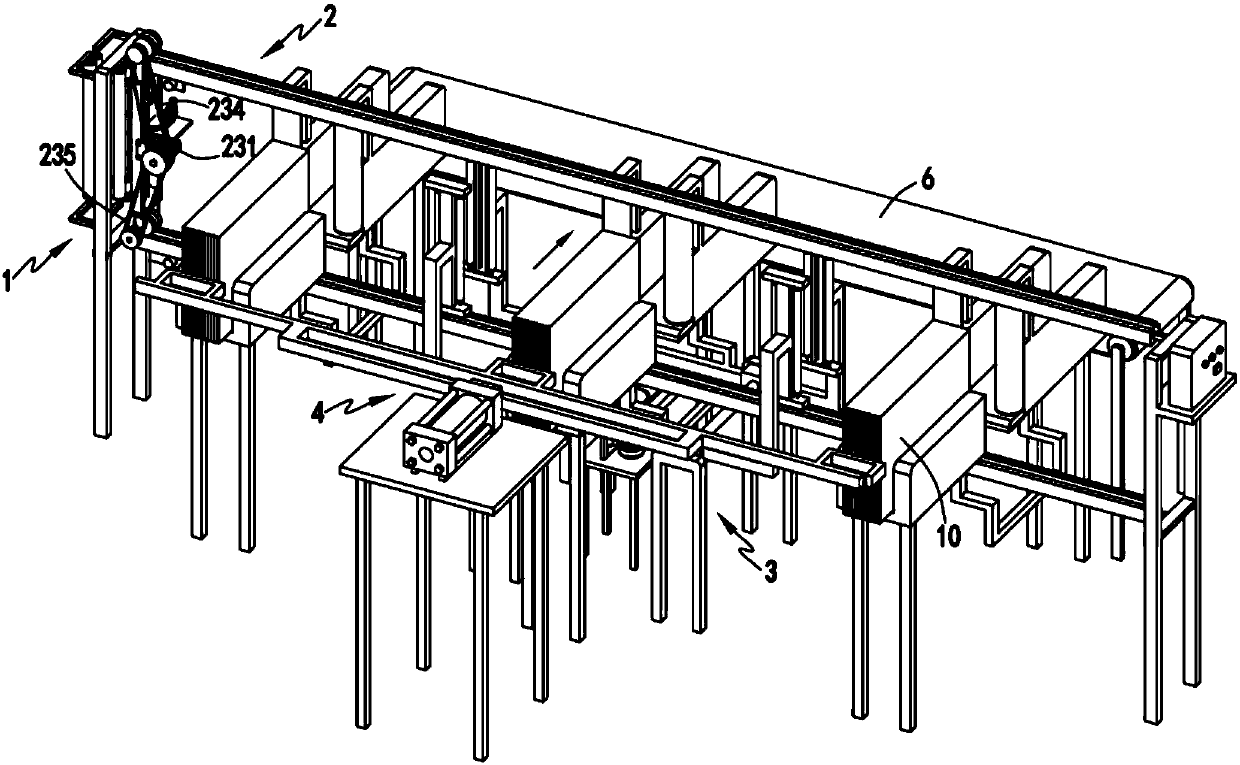

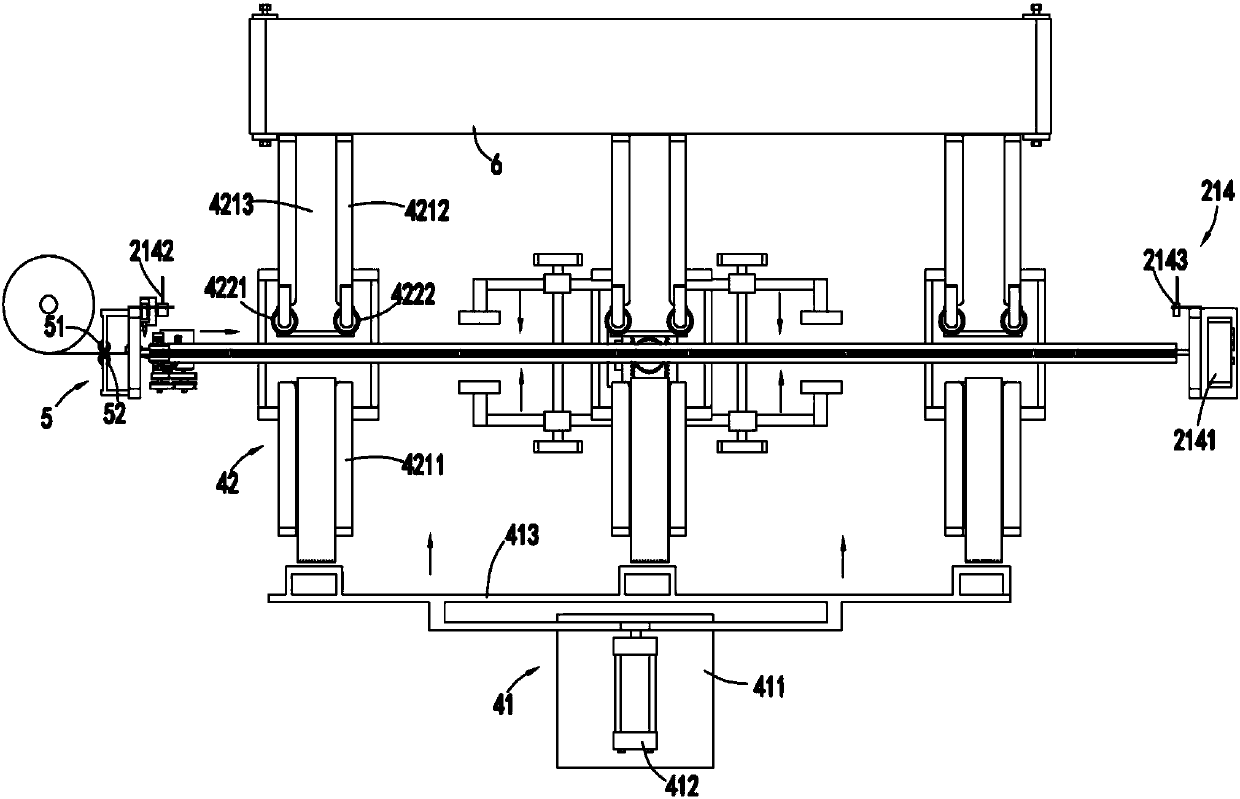

Rapid film coating process for battery pole group

ActiveCN108100336AImprove efficiencySave human effortWrapping material feeding apparatusFinal product manufactureFilm coatingEngineering

The invention relates to a rapid film coating process for a battery pole group. The rapid film coating process comprises the following steps of 1, an unreeling working procedure; 2, a thin film unfolding working procedure; 3, a thin film cutting working procedure; 4, a film coating working procedure; and 5, an output working procedure. In the step 1, a winding drum thin film is placed on an unreeling station, and a positioning mechanism is used for positioning the end part of a winding drum thin film; in the step 2, an adsorption mechanism is used for fixing the end part of a thin film at thepositioning mechanism and unfolding the thin film along a guide mechanism under the driving of a traction mechanism; in the step 3, the tail end of the thin film is cut off by a transverse cutting mechanism located at the unreeling station, cutting and positioning mechanisms positioned on the two sides of the unfolded thin film are used for equally cutting the thin film and positioning the end ofthe thin film; in the step 4, the film coating working procedure and a pole group located at the film coating station move in the direction of the thin film under the pushing of a material pushing mechanism, and the film coating mechanism is used for coating the thin film on the two sides of the polar group; and in the step 5, the polar group of the coated film is pushed to the output station to be output. According to the rapid film coating process, the problems that an existing polar group coating process is complex in process, low in coating efficiency and poor in coating effect are solved.

Owner:林浩

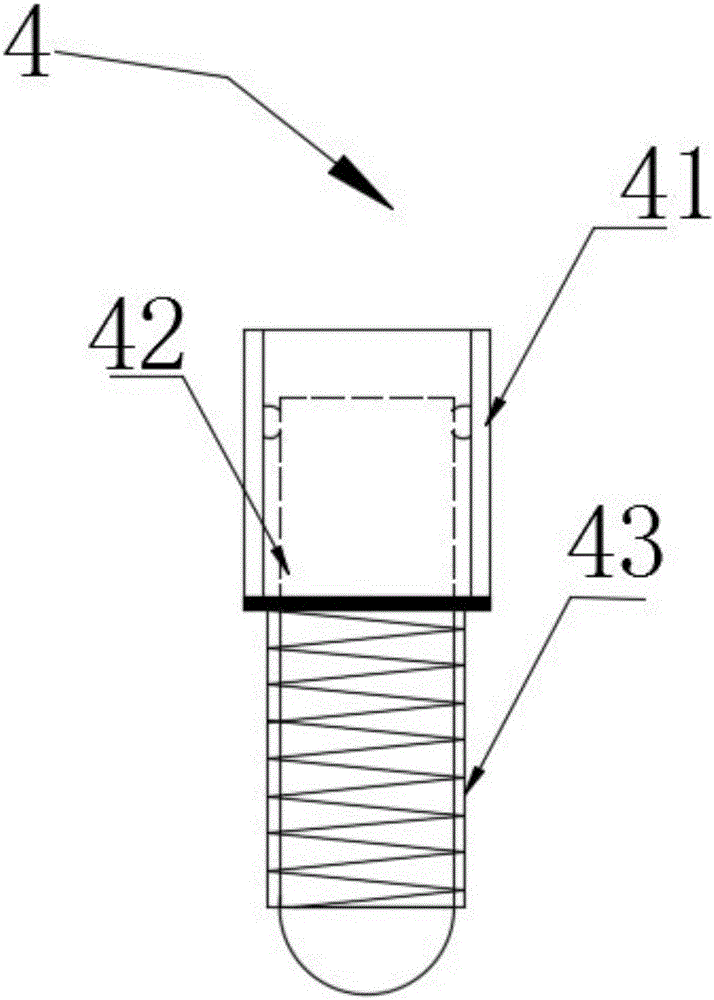

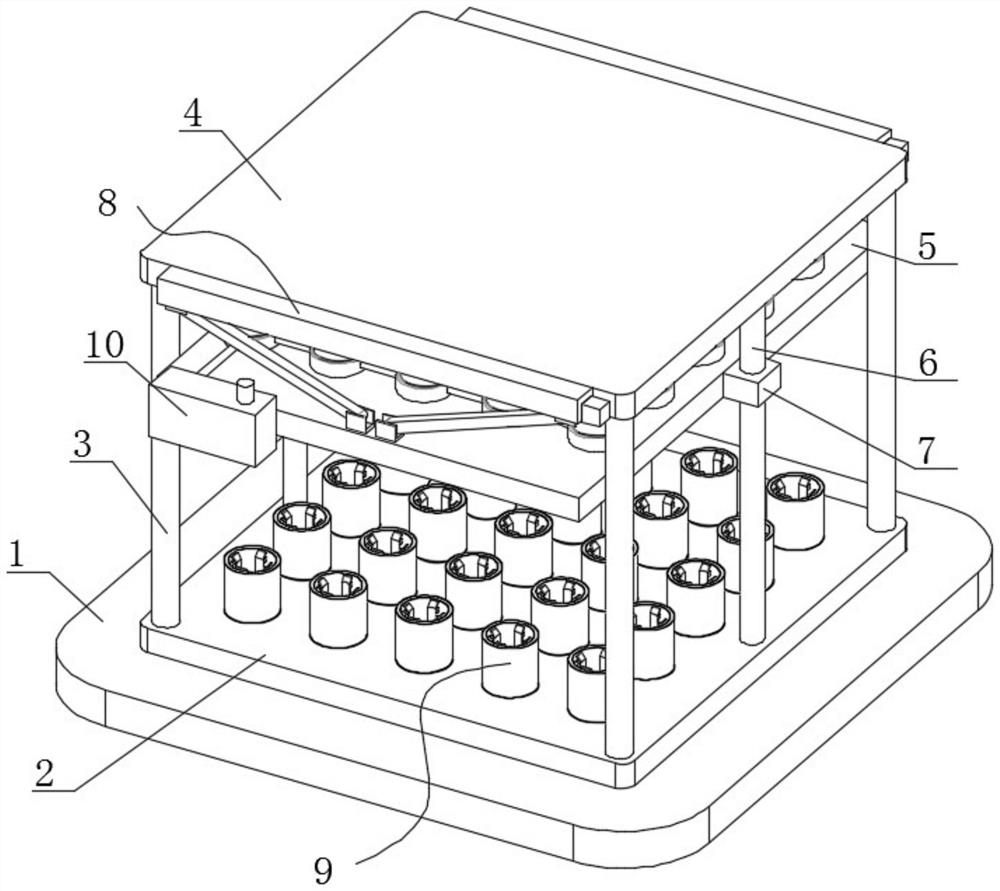

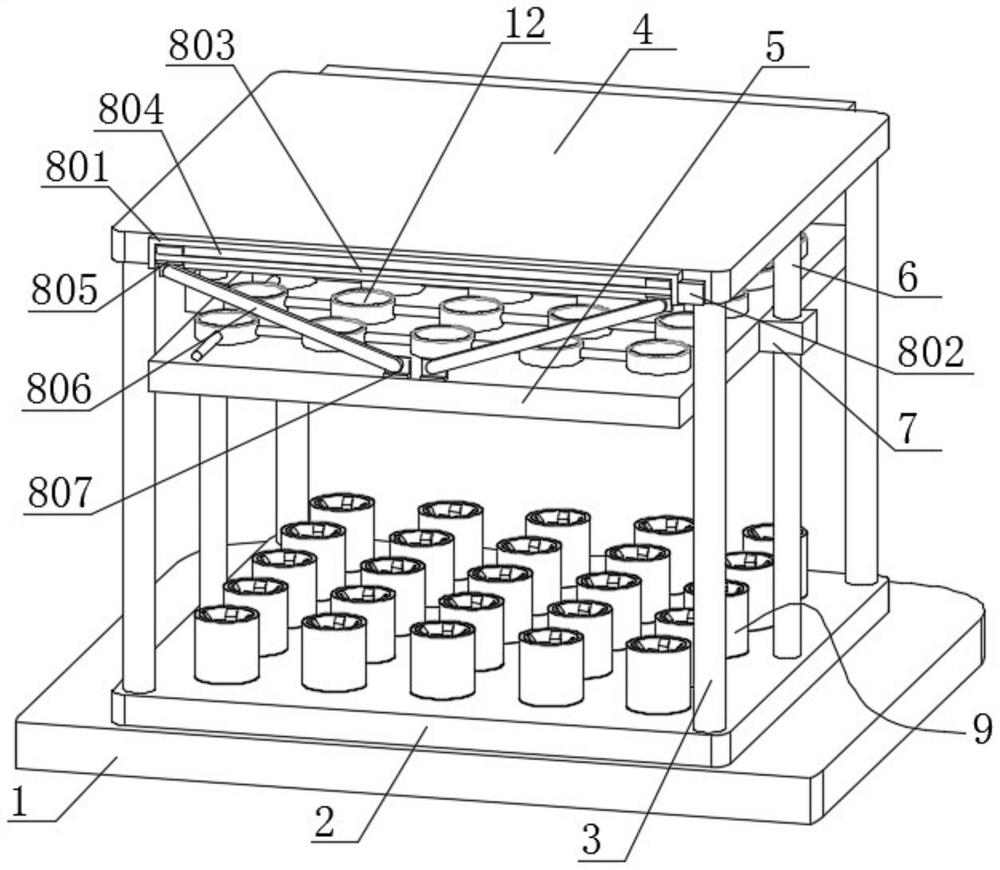

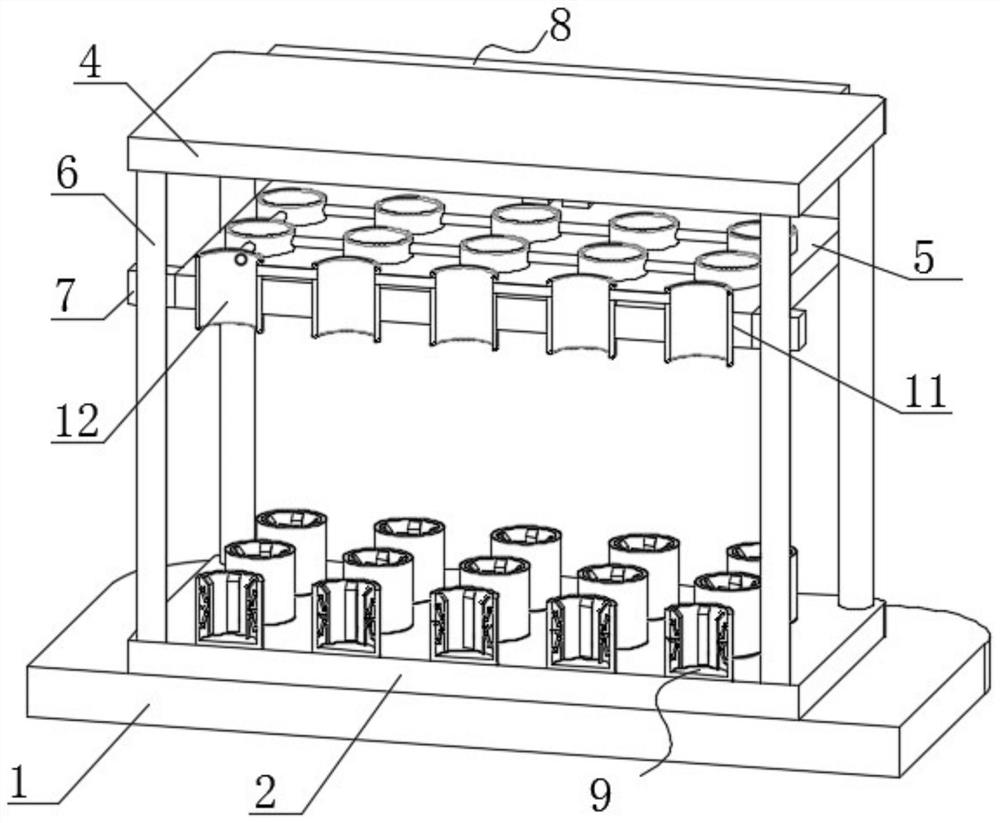

Gas cylinder container with anti-collision function and using method

InactiveCN112696611AReach the limit effectEasy accessContainer filling methodsContainer discharging methodsPost collisionGas cylinder

The invention discloses a gas cylinder container cell with an anti-collision function and a using method, and belongs to the technical field of container cells. The gas cylinder container cell comprises a bearing plate; the upper surface of the bearing plate is fixedly connected with a bottom plate; four corners of the upper surface of the bottom plate are fixedly connected with stand columns; a top plate is arranged above the bottom plate; the upper surface of each stand column is fixedly connected to the bottom surface of the top plate; lifting mechanisms are arranged on the two side faces of the top plate; a moving plate is arranged below the top plate; through holes arranged at equal intervals are formed in the moving plate; and an air bag is fixedly connected into each through hole. According to the gas cylinder container cell, the lifting mechanism is arranged, so that a gas cylinder can be automatically limited; the gas cylinder is convenient to take; the effect of clamping the gas cylinder in advance is achieved by arranging the limiting mechanism; the stability of gas is guaranteed; through an inflation and suction dual-purpose pump, the through holes and the air bags, the situation that a single gas cylinder is impacted and then transferred to other gas can be avoided; and the safety during gas storage is improved.

Owner:杭州峰峦贸易有限公司

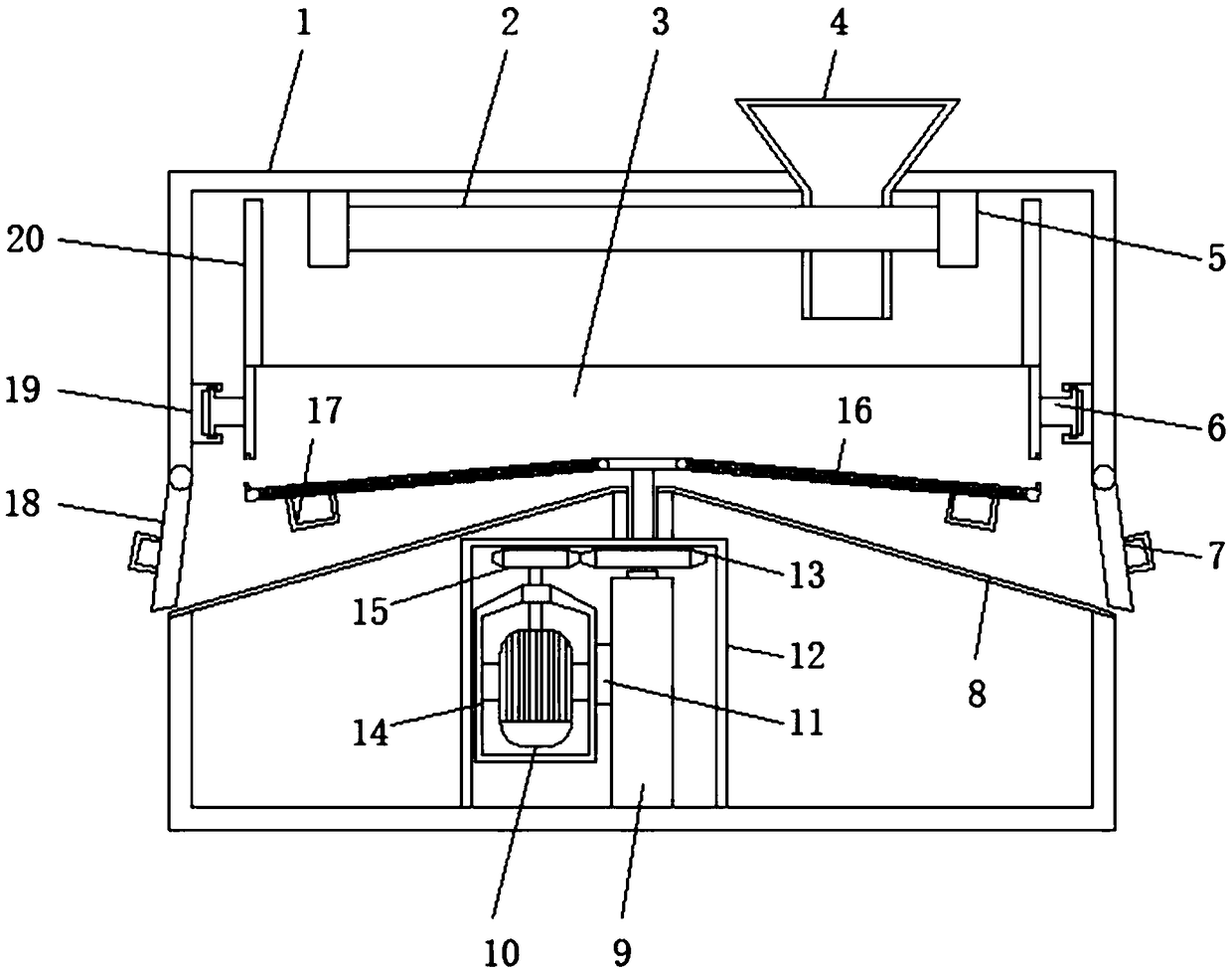

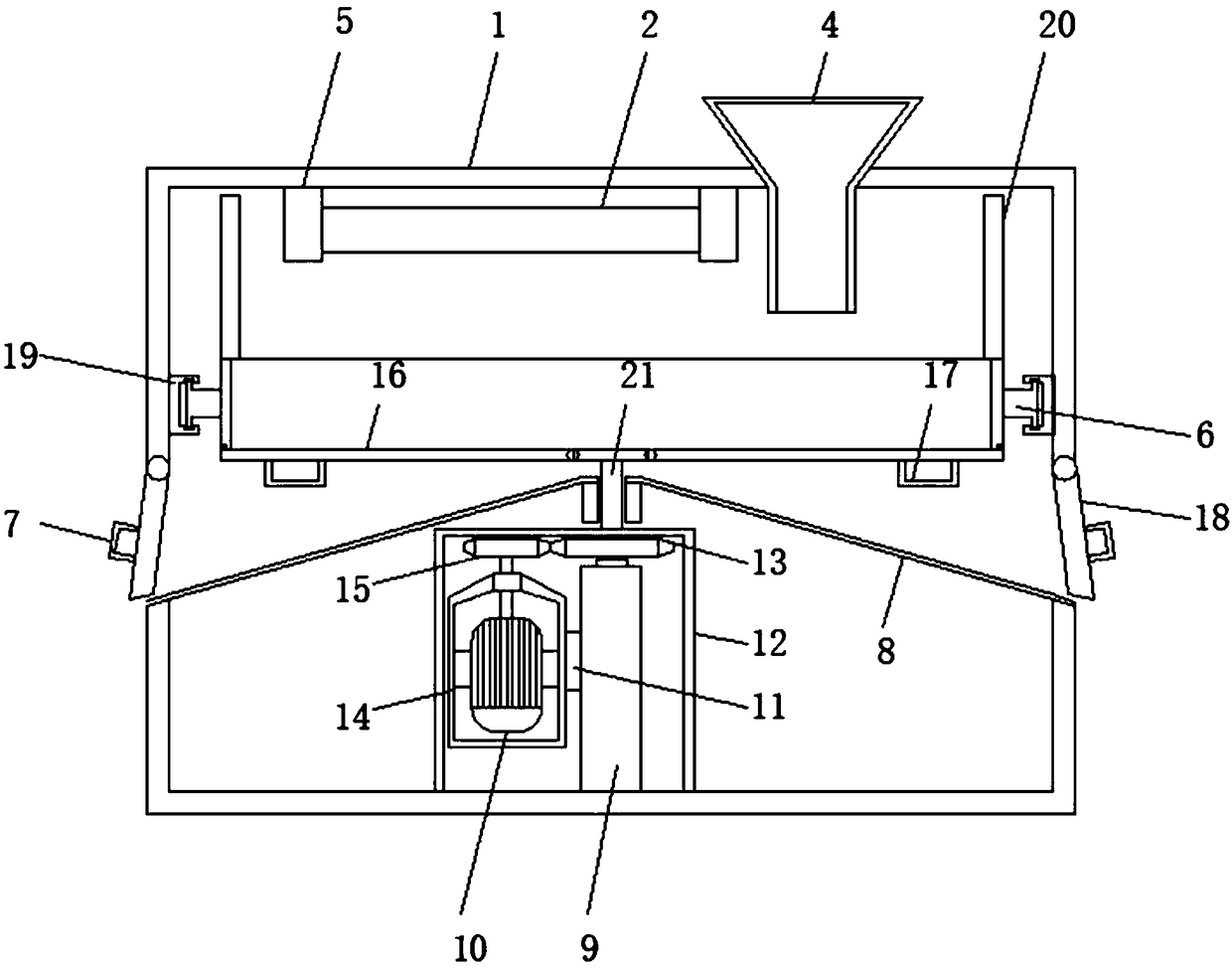

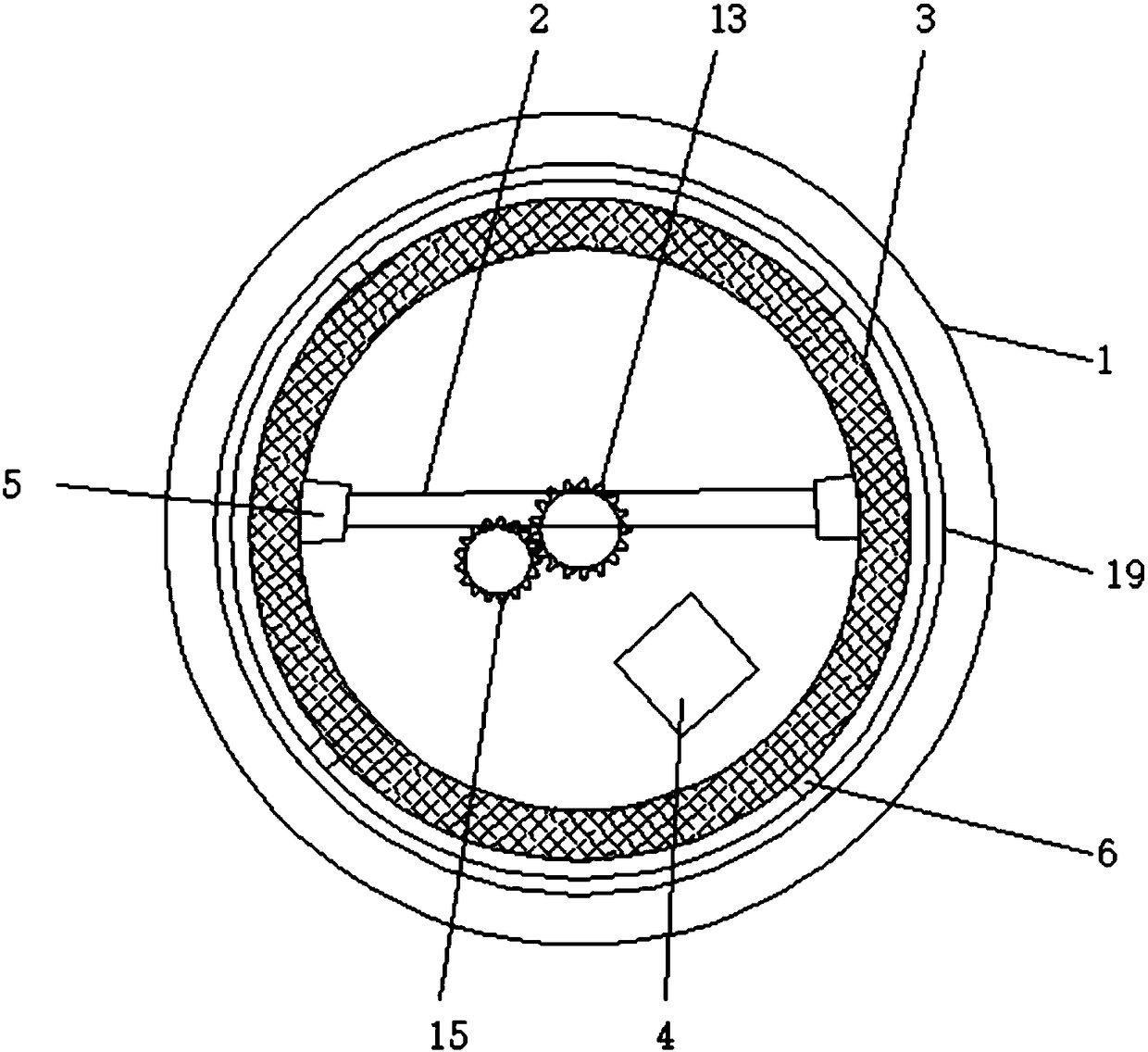

Food raw material screening and drying device

InactiveCN108435526AAchieve the effect of putting in the filter trayDry evenlySievingScreeningEngineeringRaw material

The invention discloses a food raw material screening and drying device. The device comprises a main body box, a screening disc and a protective box; a feed port is mounted at the upper end of the main body box; the protective box is fixedly mounted on the end inner wall of the lower end of the main body box; an inclined plate is fixedly mounted at the upper end of the protective box; a stand column is fixedly mounted in the protective box; a driven gear is rotationally mounted at the upper end of the stand column through a rotating shaft; a motor is mounted in the motor box; an output shaft of the motor penetrates through the inner wall of the motor box, and a driving gear is rotationally mounted; a chute is formed in the inner wall of the main body box; slide blocks are fixedly mounted on the two sides of the screening disc; screen plates, symmetrically distributed about the screening disc, are rotationally mounted on the two sides of the bottom end of the screening disc; a limitingplate is fixedly mounted on the upper end surface of the screening disc; a heating pipe is fixedly mounted on the inner wall of the upper end of the main body box through a fixed block; and the heating pipe is positioned above the screening disc. The device has the advantage of capability of drying during screening.

Owner:海宁市立派商贸有限公司

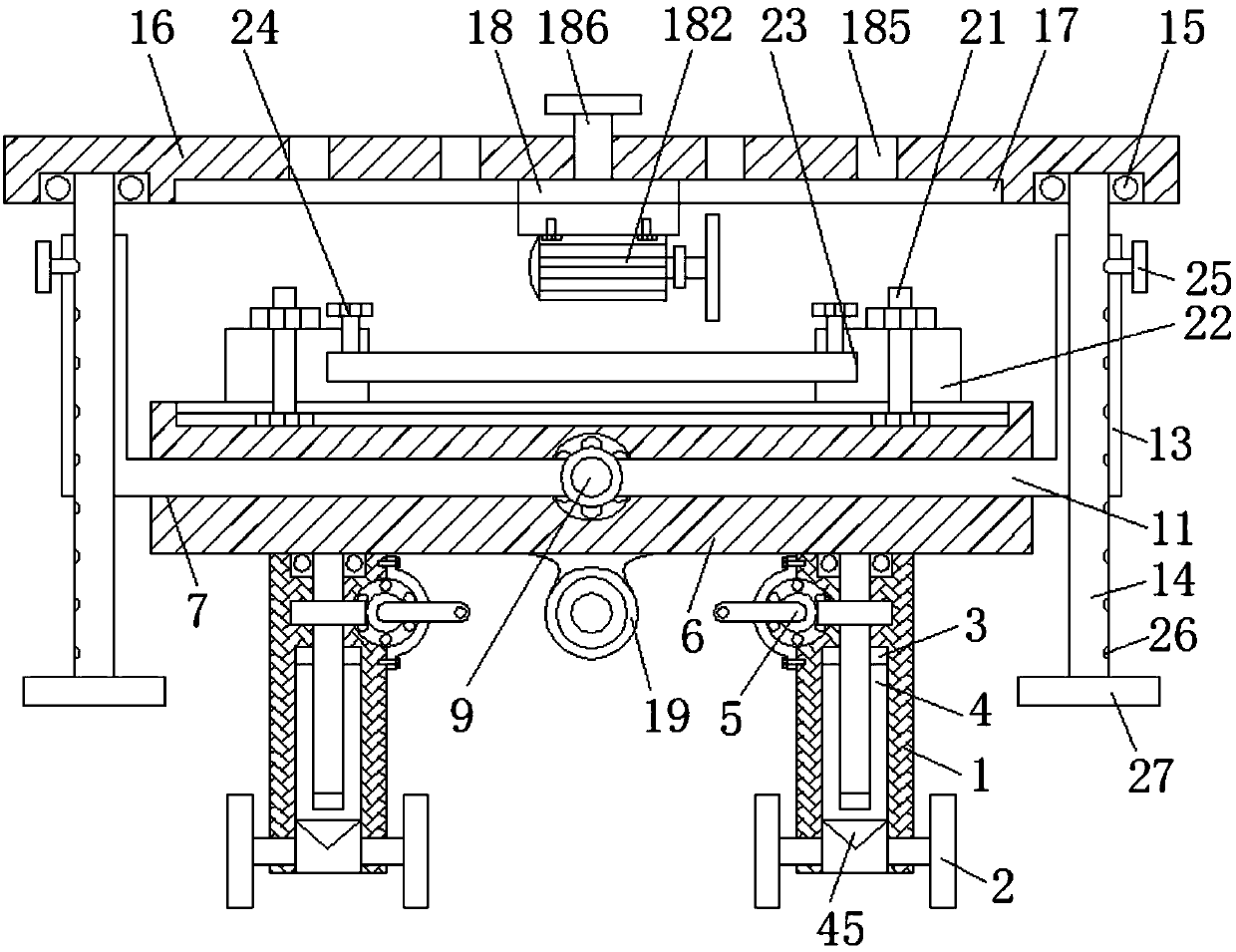

Manually-operated adjustable movable type wood processing mechanical table

InactiveCN107838893ATo achieve the mobile effectSolve the problem of increasing processing errorsMulti-purpose machinesWork benchesBolt cutterWood processor

The invention discloses a manually adjustable mobile wood processing machine table, which comprises support legs, the bottom ends of which are fixedly mounted with running wheels, and telescopic slide holes are provided inside the support legs, and lifters are arranged inside the telescopic slide holes. device, a manual control device is fixedly installed on the top of the outer surface of the supporting leg. The manual adjustable mobile wood processing machine table, the processing device includes a base, the lower surface of the base is respectively fixed with a cutting machine, a grinder and a spray gun by bolts, the inner wall of the adjustment groove and the upper surface of the base are trapezoidal, horizontal There is a positioning hole on the surface of the rod, the inner bottom wall of the positioning hole extends to the inner top wall of the adjustment groove, and the inner wall of the positioning hole is threaded with positioning bolts, which achieves the effect of multi-process processing of the wood board, and can be selected according to needs. Advanced processing tools, thus effectively solving the problem that the processing error of wood boards will become larger and larger after the conversion of multiple processes.

Owner:绍兴新越机械制造有限公司

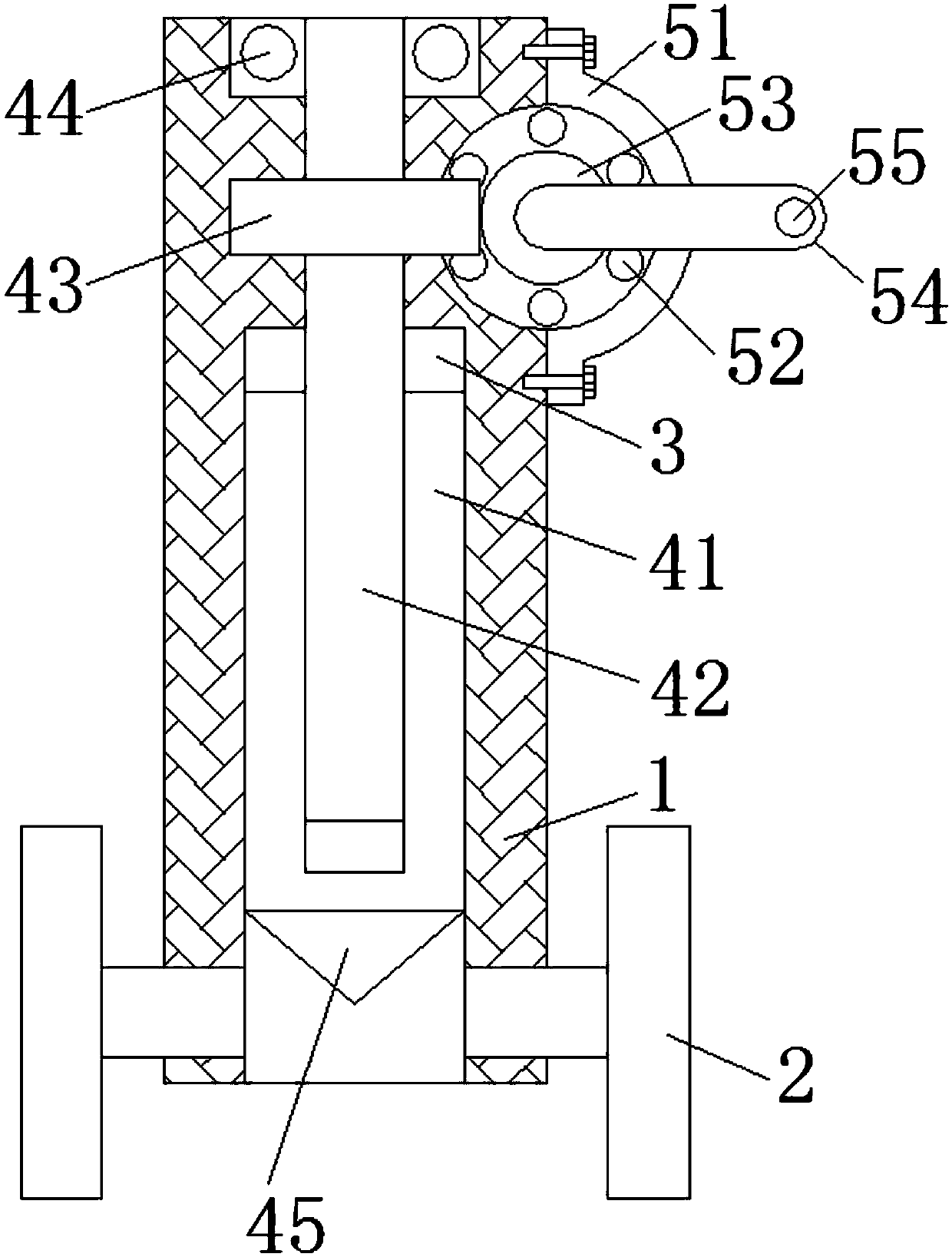

Stirring device for sealing agent

InactiveCN106582393AStir wellImprove processing efficiencyRotating receptacle mixersTransportation and packagingEngineeringSealant

The invention discloses a stirring device for a sealing agent. The stirring device comprises a base and is characterized in that a controller is fixedly mounted on the right of the top of the base, supports are fixedly mounted on two sides of the top of the base, a transverse rod is fixedly mounted at the tops of the supports, a box is fixedly mounted at the bottom of the transverse rod, a vertical rod is fixedly mounted at the top of the base and located between the two supports, a first sleeve is rotatably connected to the top of the vertical rod, a stirring barrel is fixedly mounted at the top of the first sleeve, and a gear ring is fixedly mounted at the top of the stirring barrel. The stirring device has the advantages that the sealing agent can be fully and bidirectionally stirred by improving the box, the stirring barrel can be rotated so as to conveniently stir the sealing agent, time is saved while convenience is brought to a user, and the processing efficiency of the sealing agent is increased at the same time.

Owner:WUXI HITXINCHENG POLYMER TECH

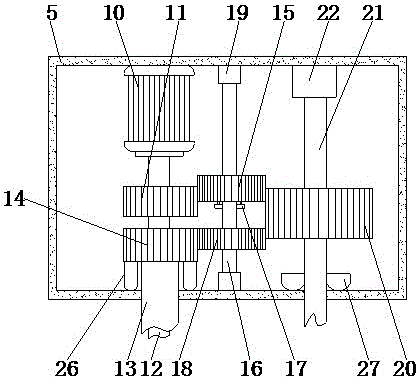

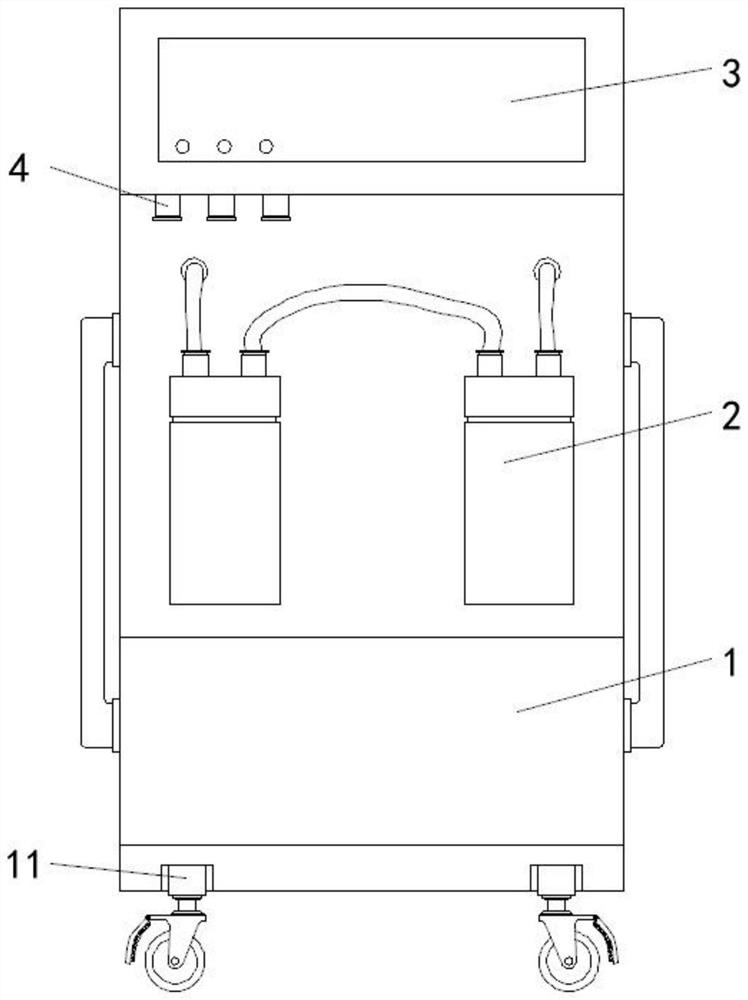

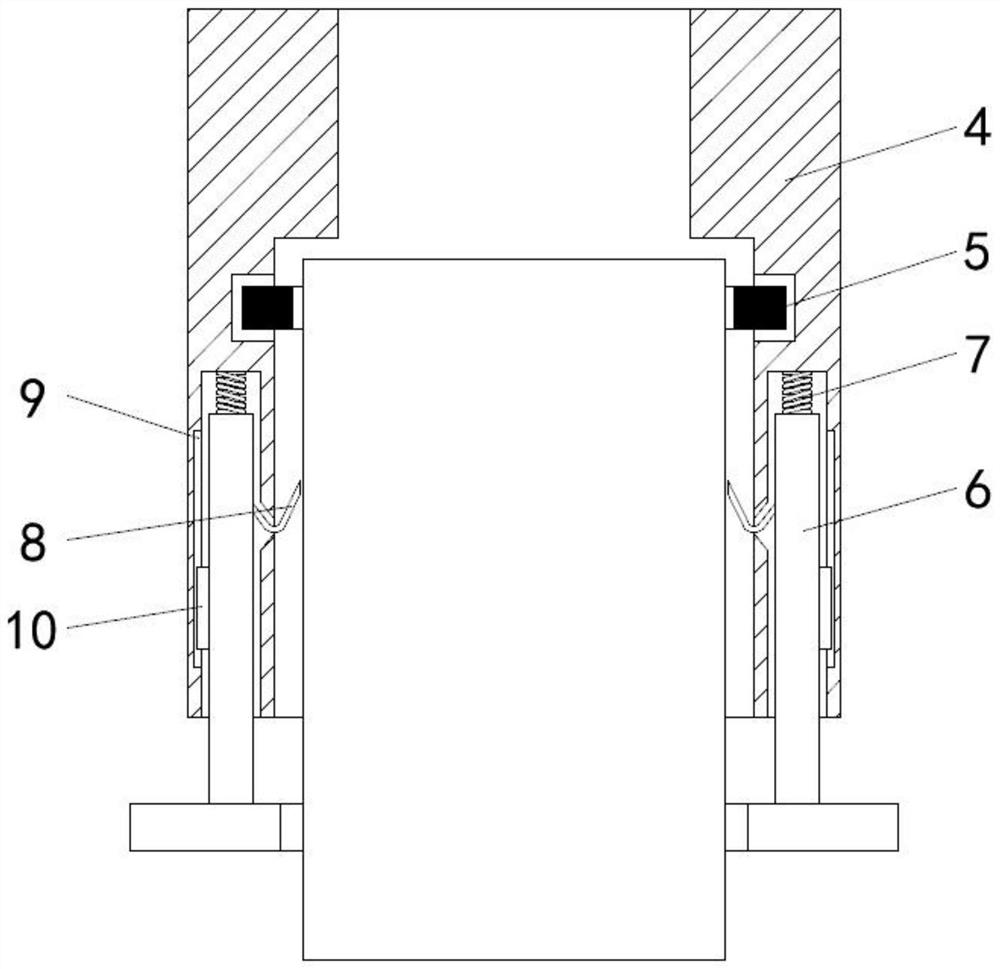

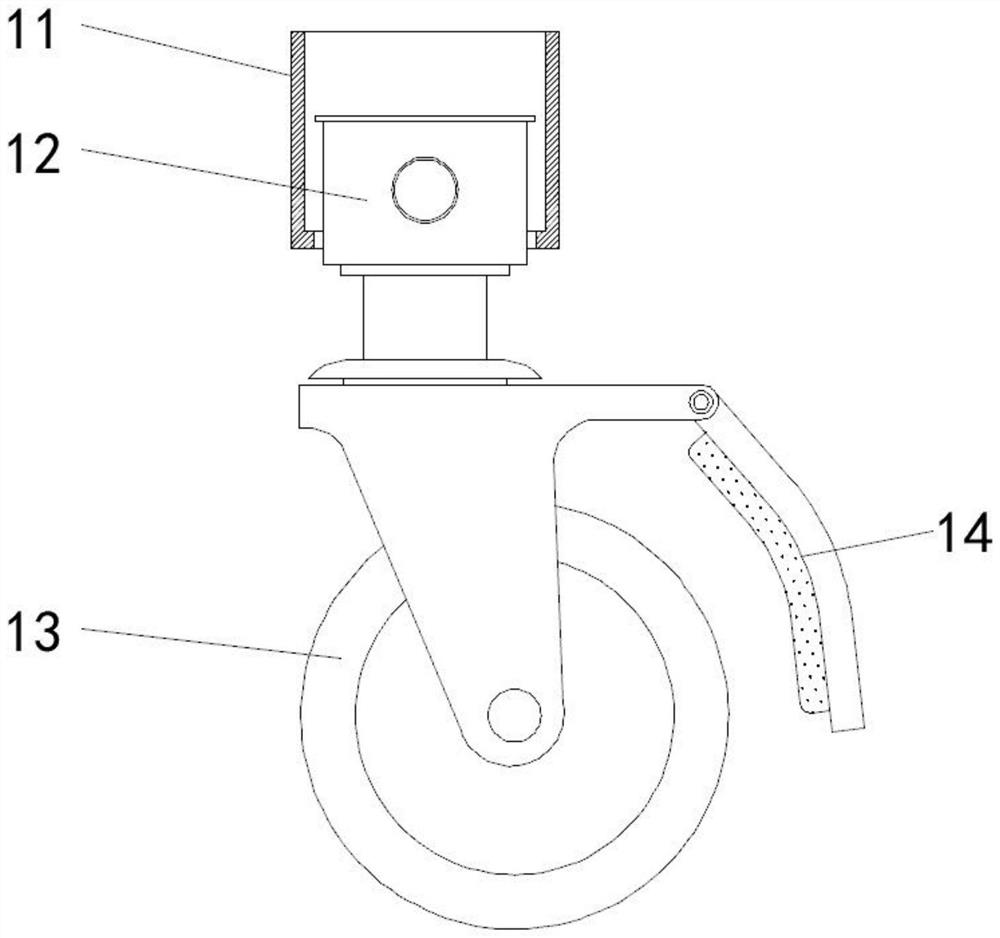

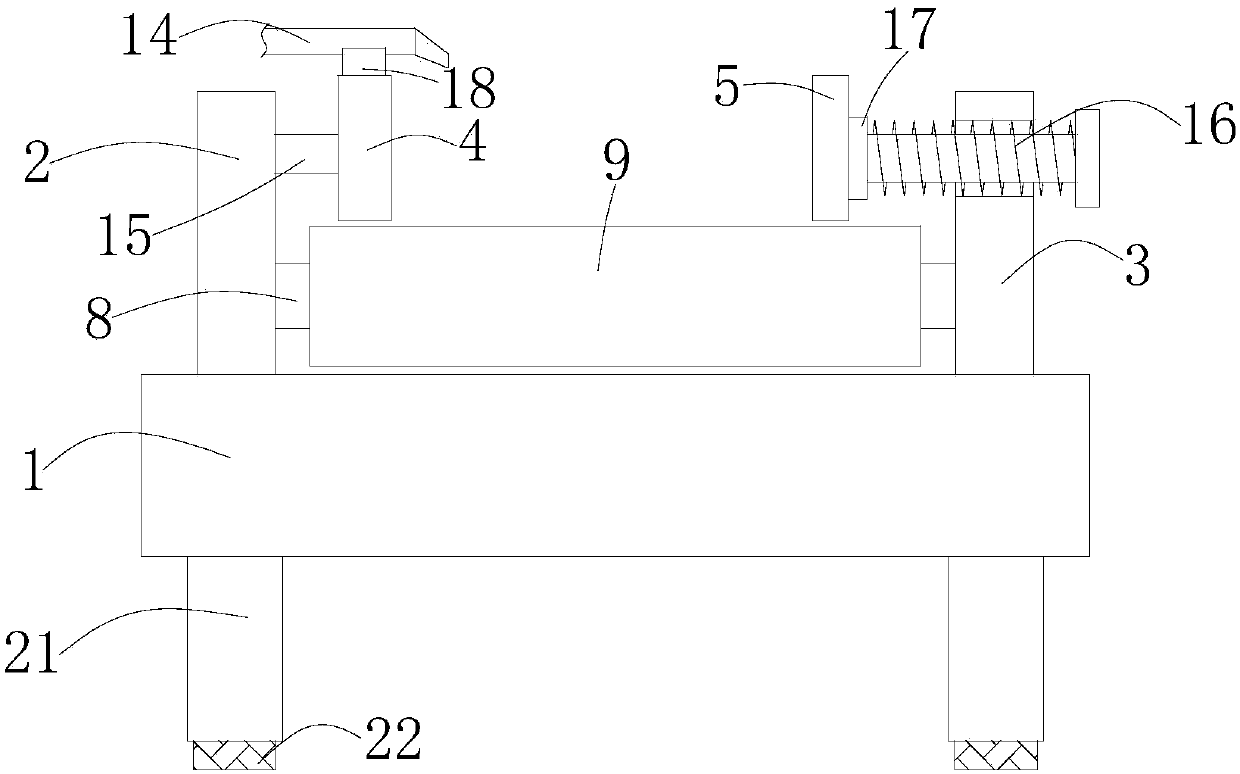

Gastric lavage device for clinical use in emergency internal medicine

ActiveCN111671993AAvoid skewAvoid laborious disassembly and assemblyCannulasEnemata/irrigatorsEmergency treatmentGastric lavage

The invention relates to the technical field of emergency treatment, and discloses a gastric lavage device for clinical use in emergency internal medicine. The gastric lavage device for the clinical use in the emergency internal medicine comprises a device body; two filter bottles are movably mounted on a front surface of the device body; a console is fixedly mounted on the front surface of the device body; and three pipe joints, which communicate with the interior of the device body, are fixedly mounted at the bottom of the console. According to the gastric lavage device for the clinical usein the emergency internal medicine, fixture blocks extrude positioning springs and shrink to the interior of positioning bases, and detach from the interior of a clamp slot while shrinking so as to slide inside second chutes along with movement of storage shelves; when the fixture blocks slide to positions corresponding to clamp slots away from the two chutes, reverse thrusting on the fixture blocks is facilitated by the positioning springs so as to have the fixture blocks clamped in the clamp slots, thereby pulling the storage shelves to ice cup fixture blocks outside the device body so as tohave the storage shelves limited. Thus, storage buckets on the storage shelves can be directly used by a medical worker; and moreover, the problem of overturning of the trash bucket and the drug liquid bucket caused by collision due to movements of the medical worker is avoided.

Owner:刘庆美

Automatic code spraying equipment for food packing

ActiveCN107672311AAchieve the effect of rotationTo achieve the mobile effectTypewritersOther printing apparatusAutomatic test equipmentBarcode

The invention discloses automatic code spraying equipment for food packing. The automatic code spraying equipment comprises a base; the two sides of the top of the base are fixedly connected with a first fixed plate and a second fixed plate correspondingly; a first clamping plate is arranged on the right side of the first fixed plate; a second clamping plate is arranged on the left side of the second fixed plate; a motor is fixedly connected to the rear end of the left side of an inner cavity of the first fixed plate; and a rotating shaft of the motor is fixedly connected with a first rotatingshaft. The first rotating shaft is driven to rotate by arranging the motor; a conveying belt is driven to rotate through the first rotating shaft and a second rotating shaft; a baffle is driven to move through an electric telescopic rod; foods are detected through an infrared sensor; the foods are blocked through the baffle; and codes are sprayed on the foods through a spray head of a barcode printer. The codes can be sprayed on the foods automatically, and manual operation is not needed.

Owner:江苏正华包装有限公司

Intermittent-type carrying device with limiting function

The invention discloses an intermittent-type carrying device with a limiting function, and relates to the technical field of conveying devices, solving the problems of serious energy waste and low working efficiency during existing bogie maintenance. The intermittent-type carrying device comprises a trolley and a carrying track. A traveling cavity is formed in the lower end of the trolley. A firsthydraulic cylinder and a sliding arm are fixed to the trolley. The first hydraulic cylinder sleeves a first hydraulic rod. A first slider is connected to one end, located on the outer portion of thefirst hydraulic cylinder, the first hydraulic rod, and sleeves the sliding arm. A first sliding rod is connected to the first slider. A first rotating rod is connected to one end, away from the firstslider, of the first sliding rod. One end of the first rotating rod is connected to the trolley. A first push block is connected to the other end of the first rotating rod. The intermittent-type carrying device has the advantages of high carrying speed, high working efficiency, energy conservation and simplicity in operation.

Owner:成都岁生科技有限责任公司

Automatic circulating device of printing, dyeing and boiling-off

InactiveCN107338603AAchieve the effect of sliding up and down cycle cookingTo achieve the effect of circular cookingTextile treatment containersTextile treatment machine arrangementsCouplingEngineering

The invention discloses an automatic circulating device of printing, dyeing and boiling-off. The device comprises supporting legs, a boiling-off tank is fixedly connected with the tops of the supporting legs, a water inlet and a water outlet are formed in the top and the bottom of the boiling-off tank respectively, circulation inlets and circulation outlets are formed in the inner bottom wall and the inner top wall of the boiling-off tank respectively, a supporting plate is fixedly connected with the middles of the supporting legs, a stirring motor is fixedly connected with the middle of the supporting plate, a first threaded rod is fixedly connected with the output shaft of the stirring motor through a coupling, and the top of the first threaded rod penetrates the boiling-off tank and extends to the upper surface of the boiling-off tank. According to the automatic circulating device of printing, dyeing and boiling-off, the effect that circulating boiling-off is conducted on material to be boiled off in a vertically sliding mode is achieved, the material to be boiled off is placed in a cavity in the middle portion of a placing rod, a first threaded tube drives the material to be boiled off to slide vertically after being connected with the first threaded rod, and the effect that vertical circulation is conducted on hot water in the boiling-off tank is achieved, so that the problem that the temperature is likely to be uneven is solved.

Owner:范威

Multifunctional hardware wrench

The invention discloses a multifunctional hardware wrench. The multifunctional hardware wrench comprises a first support plate, wherein a head is fixedly connected to the left side of the first support plate, a first through hole is formed in the right side of the front surface of the head, a first long hole is formed in the right side of the first support plate, a second support plate is arrangedin the first long hole, a first fixed block is fixedly connected to the left side of the second support plate, and a first groove which is matched with the first fixed block is formed in the left side of the front surface of the first support plate. According to the multifunctional hardware wrench, the first support plate is arranged, so that the effect of fixing the head and the second support plate is achieved; the first through hole is formed, so that the effect of removing bolts of different sizes is achieved; the first support plate and the second support plate are arranged, so that theeffect of increasing the wrench holding length of a user is achieved; a clamping block and a clamping groove are arranged and formed, so that the effect of fixing a connecting block is achieved; and ascrewdriver head is arranged, so that the effect of removing bolts and screws is achieved. The wrench has multiple functions and is convenient to use by the user.

Owner:WUXI AOYUTE NEW TECH DEV

Dedusting mechanism of transverse cutting machine used for production of crush-resistant corrugated base paper

InactiveCN109719790AImprove practicalitySolve the problem of automatic dust removalDispersed particle filtrationMetal working apparatusPulp and paper industryExhaust pipe

The invention discloses a dedusting mechanism of a transverse cutting machine used for production of crush-resistant corrugated base paper. The dedusting mechanism comprises a transverse cutting machine body. Supporting columns are fixedly connected to the two sides of the top of the transverse cutting machine body. A transverse plate is fixedly connected to the tops of the supporting columns. A transmission mechanism is fixedly connected to the left side of the top of the transverse plate. A transmission roller is arranged on the inner sides of the supporting columns. Limiting bearings are fixedly connected to the two sides of the transmission roller. A limiting box is fixedly connected to the outer side of each limiting bearing. According to the dedusting mechanism, an air draft head isarranged to drive a wiping plate to move rightwards to wipe blades, removed scraps are collected by the air draft head and are transferred into a hose, the hose transfers the scraps into an exhaust fan, the exhaust fan transfers the scraps into an exhaust pipe, the exhaust pipe transfers the scraps into a dedusting box, the scraps are filtered through a filter screen in the dedusting box, and thus, an automatic dedusting effect is achieved.

Owner:YIWU YINAN PAPER IND CO LTD

Packaging box for clothing transportation

InactiveCN108639504AAdjustable sizeIncrease the use volumeGarmentsContainers preventing decaySoftware engineeringMicro motor

The invention provides a packaging box for clothing transportation. The packaging box comprises a box body, a box cover is hinged to the left side of the box body through a fixing bolt, an extending cover is arranged inside the box cover, a left moving chamber and a right moving chamber are fixedly installed on the left side and the right side of the box cover correspondingly, a sliding rail is fixedly installed on the right side of the inner wall of the right moving chamber, and the right side of the extending cover is in sliding connection with the sliding rail; and the left side of the extending cover extends into the interior of the left moving chamber of the box cover, the left side and the right side of the box body are correspondingly provided with first storage grooves, and an extending box is arranged inside the first storage grooves. According to the packaging box for the clothing transportation, through the arrangement of the extending box in the first storage grooves, the size of the packaging box can be adjusted, a micro motor is controlled to drive a first screw rod to rotate, an adjusting rod is enabled to adjust the height of the extending box, so that the use volume of the packaging box can be expanded conveniently; and when the use volume of the packaging box becomes large, an inner limiting rotating shaft is enabled to be rotated by pushing a telescopic fixing key so as to extend the extending cover.

Owner:湖州亲宝贝进出口有限公司

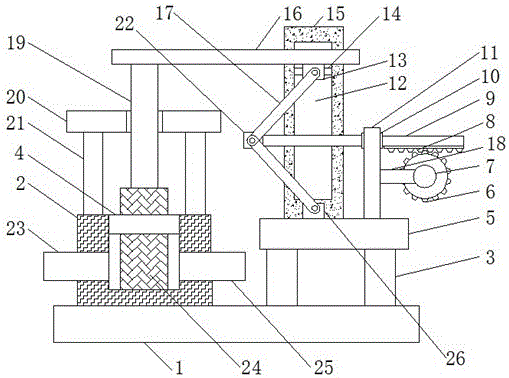

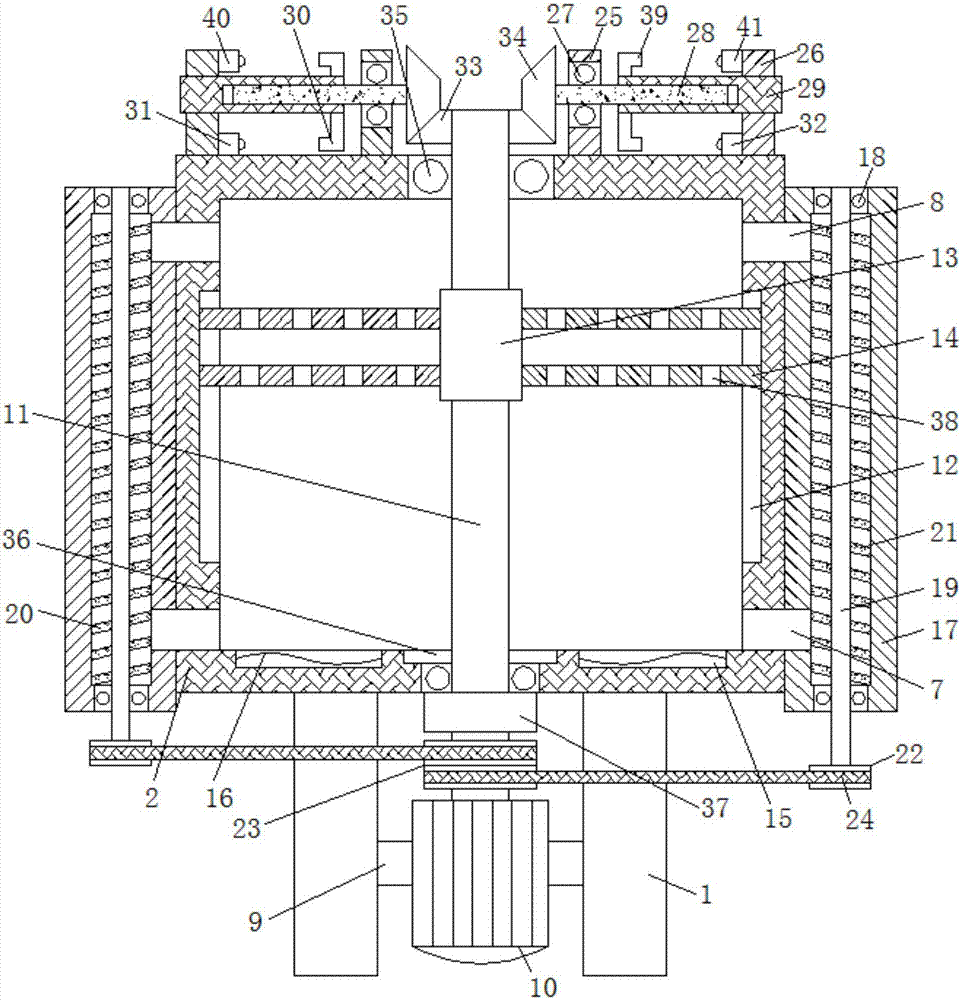

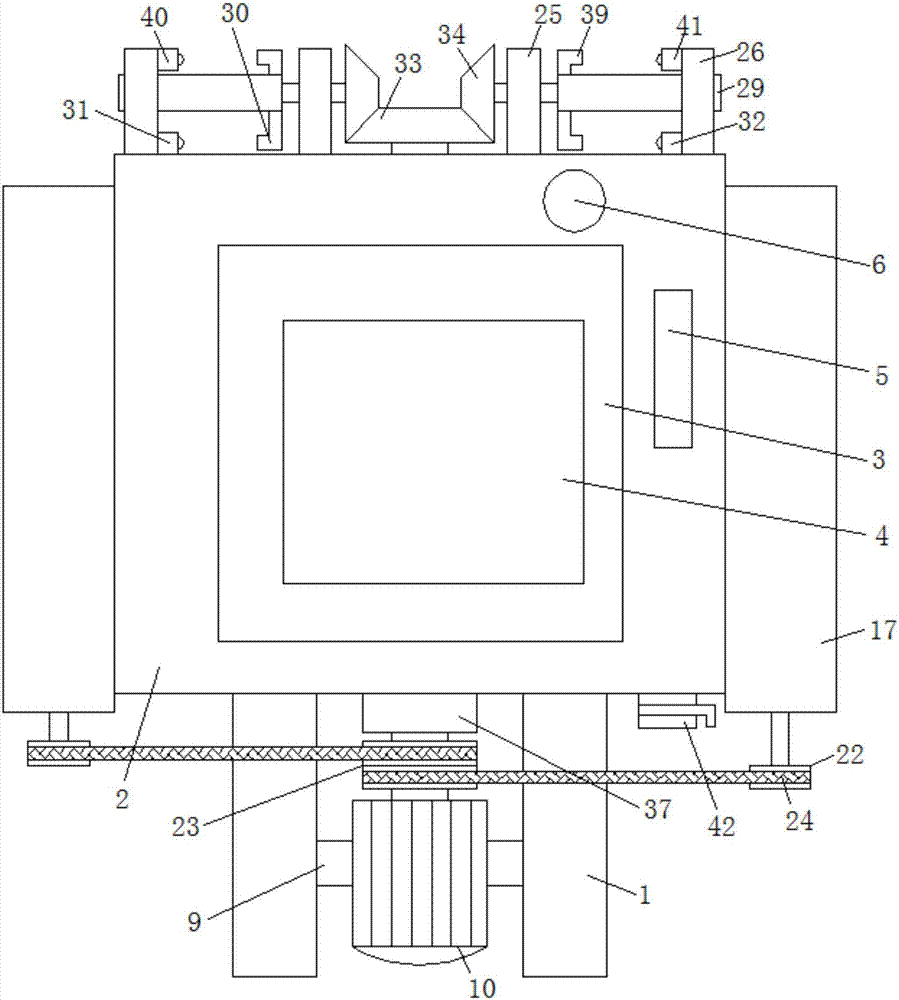

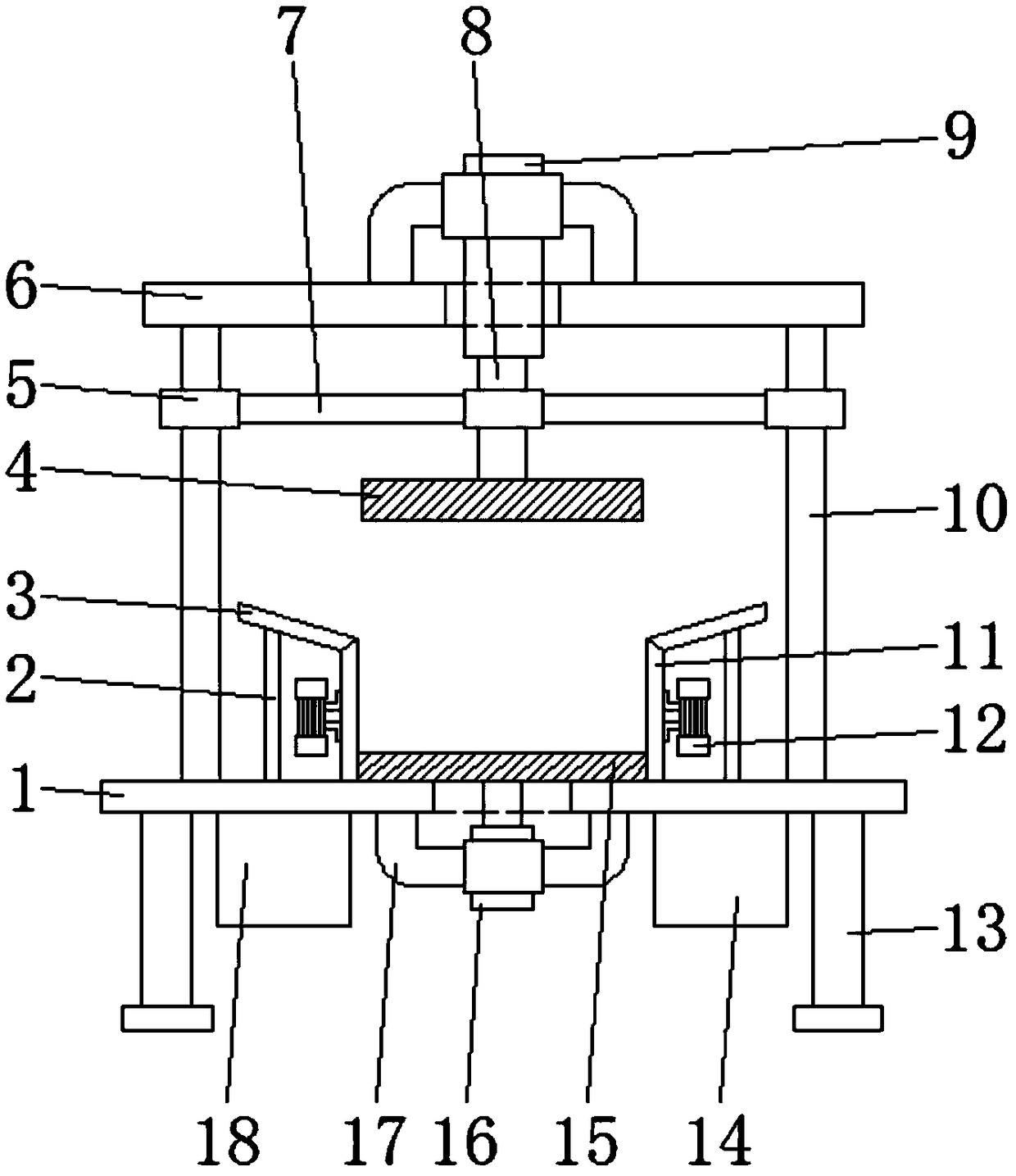

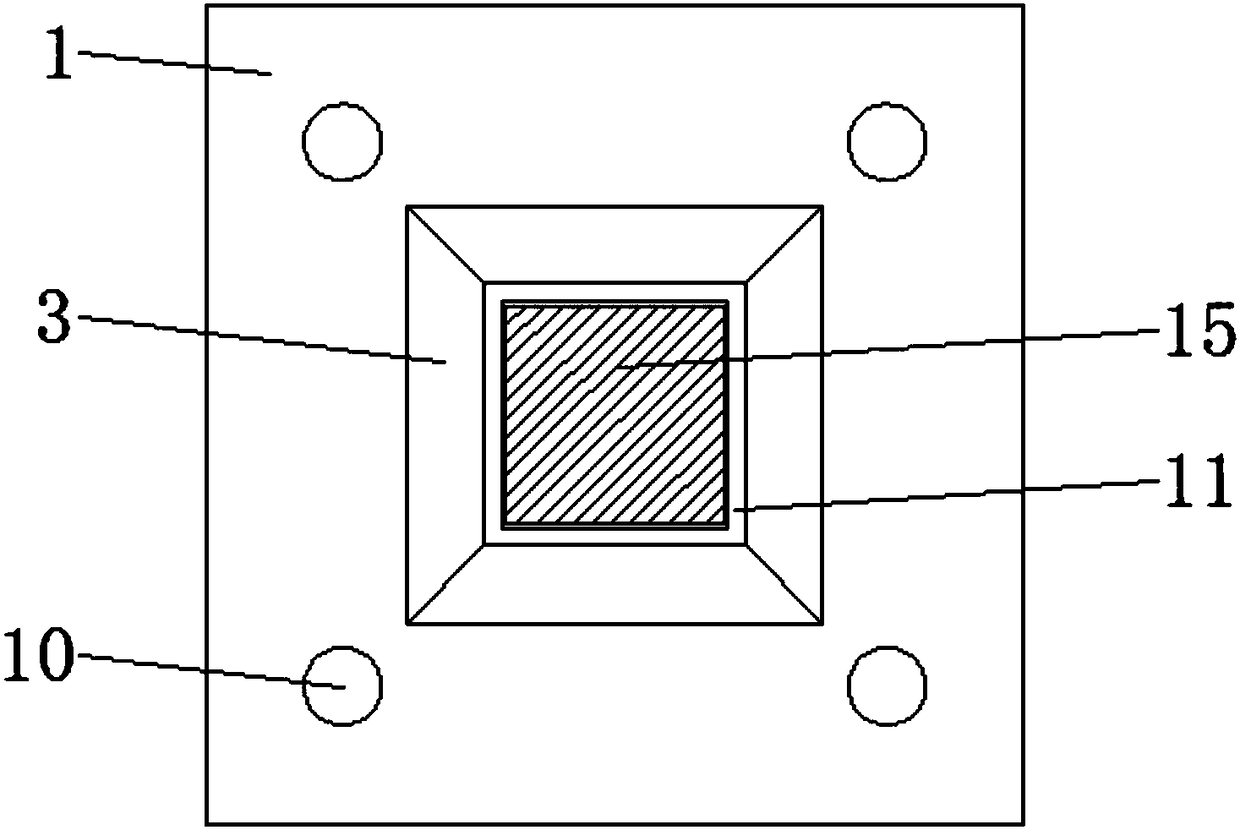

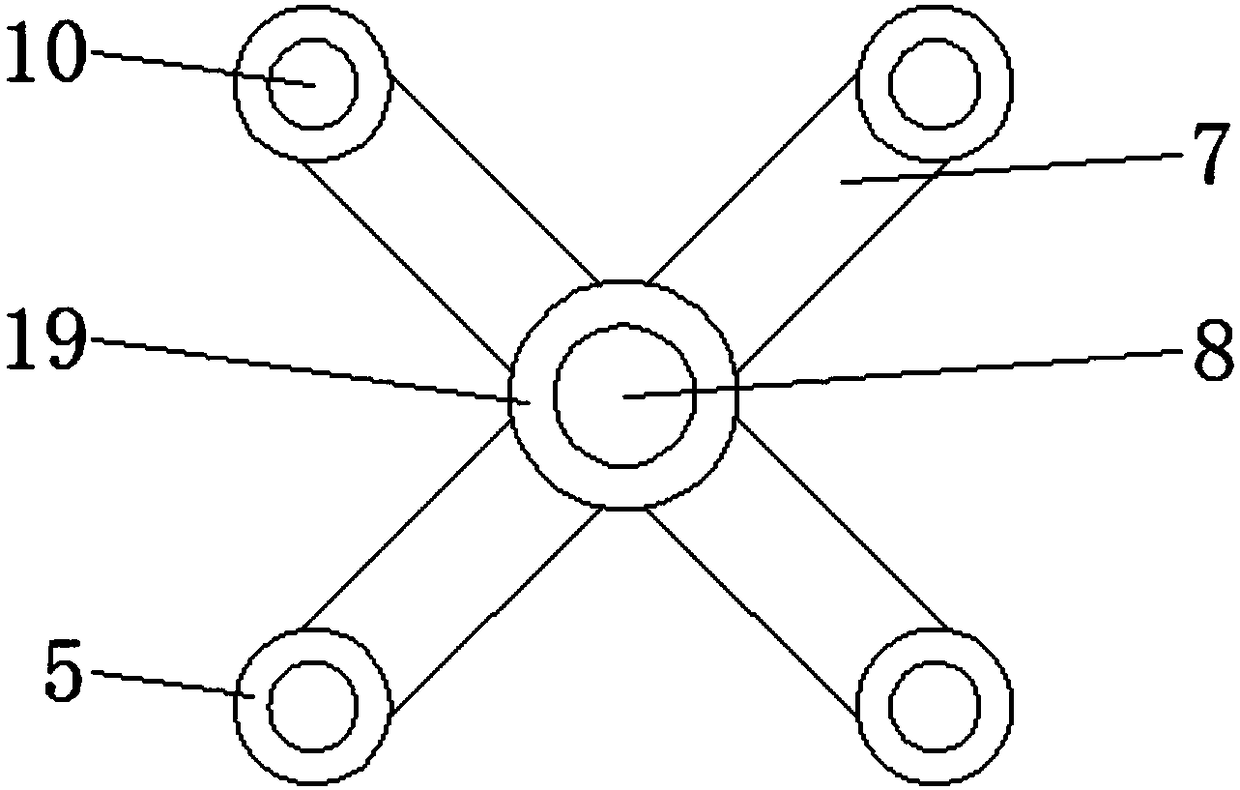

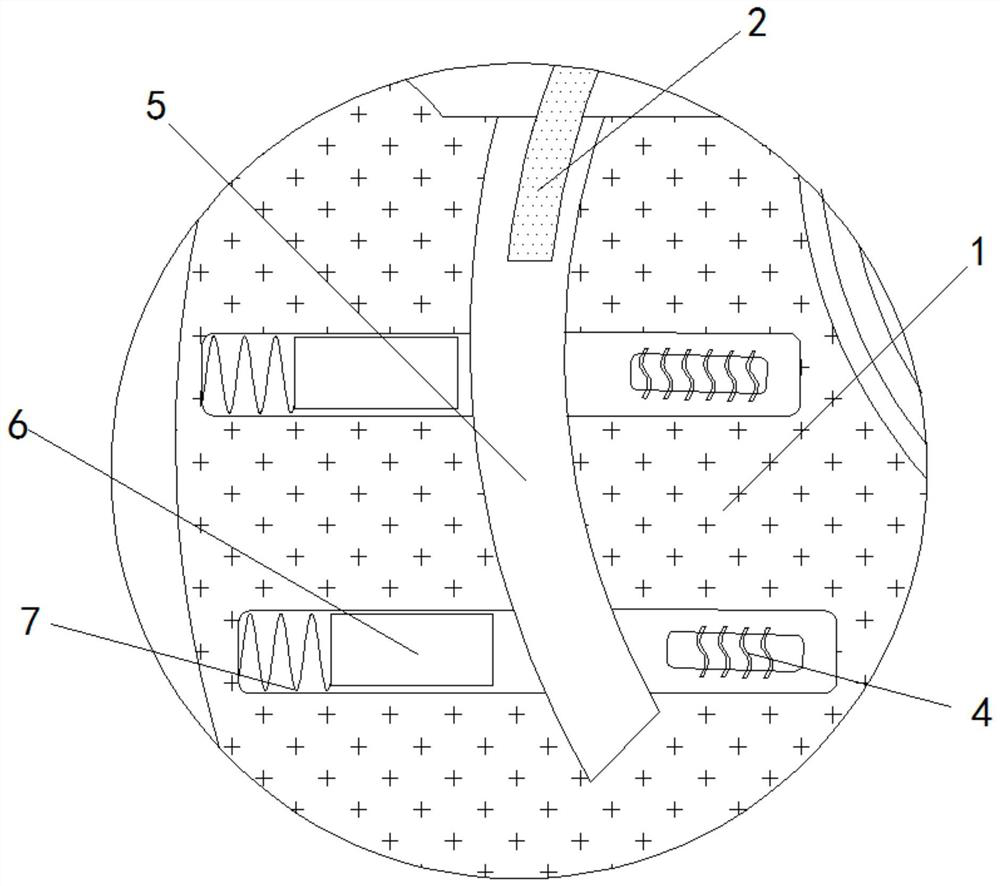

Environmental-protection ceramic brick press

PendingCN108582424AReach the limit effectAvoid the Consequences of OffsetCeramic extrusion diesHydraulic cylinderBrick

The invention discloses an environmental-protection ceramic brick press. The environmental-protection ceramic brick press comprises a limiting plate, a fixed plate, a first hydraulic cylinder, a support rod and a second hydraulic cylinder; the support rod is fixed on the upper surface of the limiting plate; a mold plate is fixed on the upper surface of the limiting plate; a vibration motor is mounted on the outer wall of the mold plate; the second hydraulic cylinder is mounted on the lower surface of the limiting plate; the fixed plate is mounted at the upper end of the support rod; the firsthydraulic cylinder is mounted on the upper surface of the fixed plate; the lower surface of the first hydraulic cylinder is connected with a pressing plate through a hydraulic rod; a first limiting bearing sleeves the outer wall of the support rod; and the outer wall of a second limiting bearing is connected with the outer wall of the first limiting bearing through a connecting rod. Through arrangement of the vibration motor, the vibration can be transferred onto a mold plate to enable raw materials in the mold plate to become more compact for extrusion molding; and the hydraulic rod can be limited through the first limiting bearing and the second limiting bearing to prevent the deviation phenomenon of the pressing plate.

Owner:泉州利达机器有限公司

Airing device for automatically turning over corn

InactiveCN109452359AImprove stabilityWon't shakeSeed preservation by dryingFood dryingArchitectural engineeringVibration motor

The invention discloses an airing device for automatically turning over corn. The device comprises a base, support rods are fixedly connected to both sides of the top of the base, a vibration box penetrates the top of the surface of each support rod, both the top and the bottom of the inner cavity of the vibration box are fixedly connected to springs, and one end, far away from the vibration box,of each spring is fixedly connected to a fixing plate. According to the invention, through the arrangement of the supporting rods, the vibration box, the springs, the fixing plate, a connecting rod, afilter plate and a vibration motor, the effect of jointly constructing the airing device for automatically turning over corn is achieved, the supporting rods can increase the stability of the vibration box, and the springs and the fixing plate can support the buffering force of the connecting rod, so that the filter plate does not shake during vibration; and through the arrangement of the filterplate and the vibration motor, the vibration motor vibrates to realize the vibration of the filter plate so as to realize the automatic turn-over of corn, so that the problems of troublesome operationand low efficiency of the existing corn airing mode are solved.

Owner:许昌泰禾农业科技发展有限公司

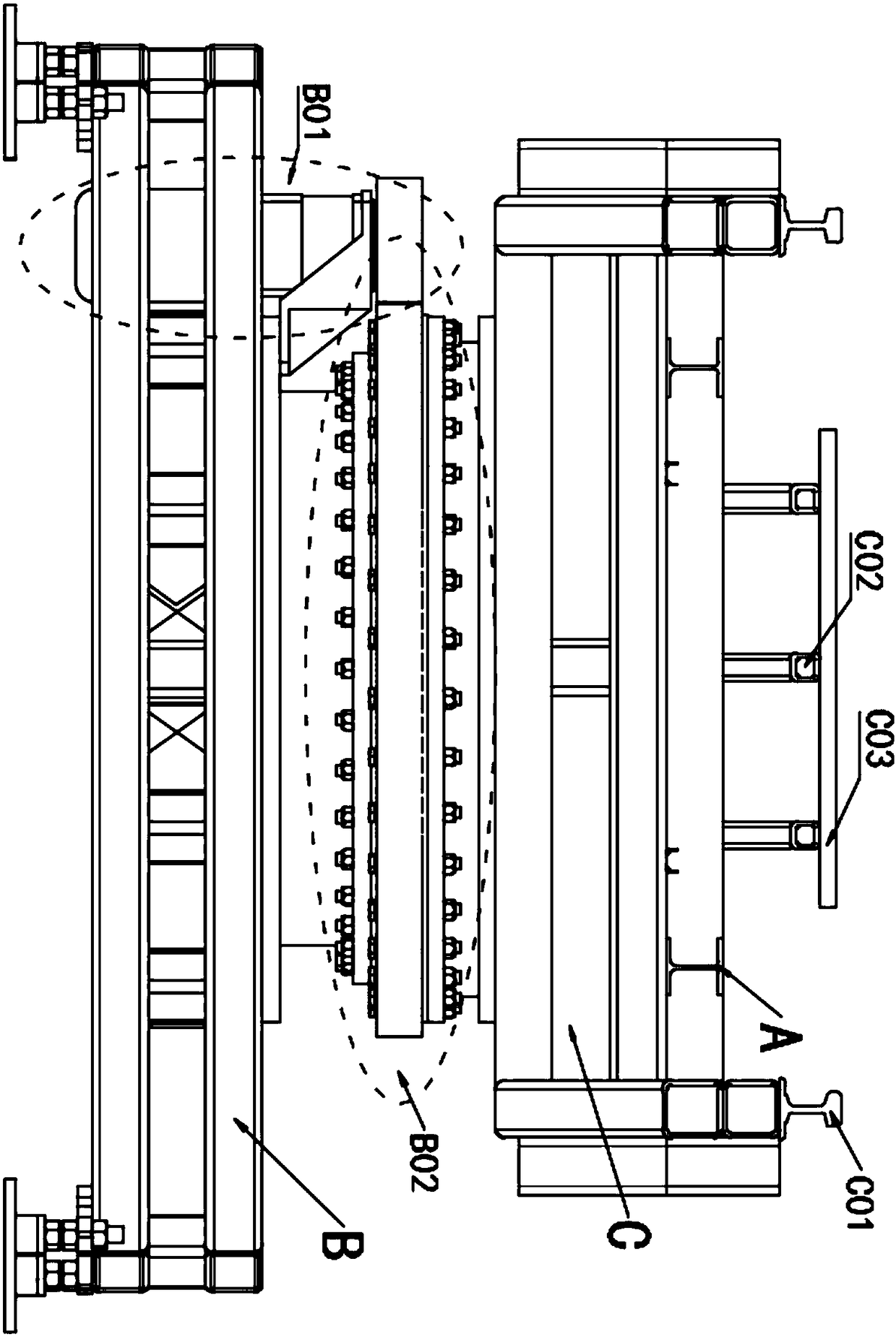

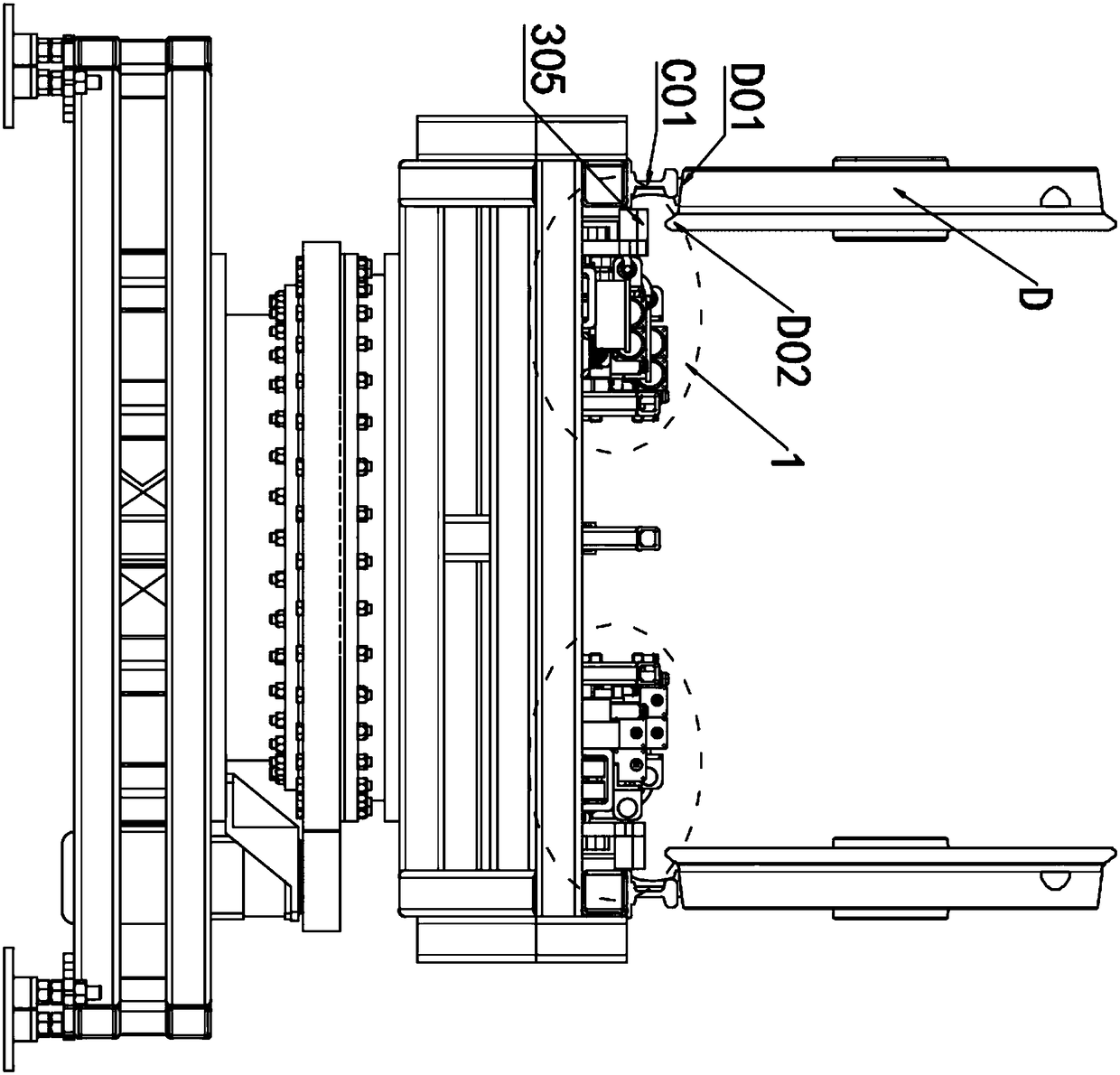

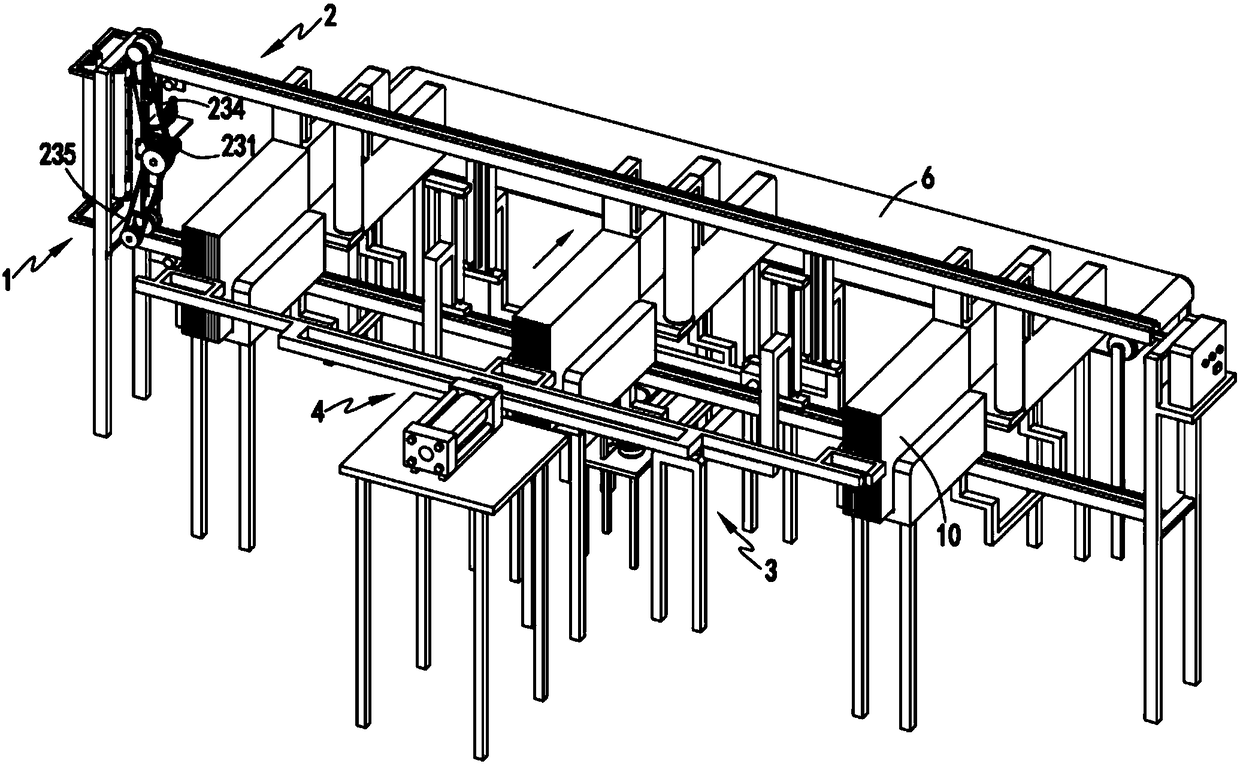

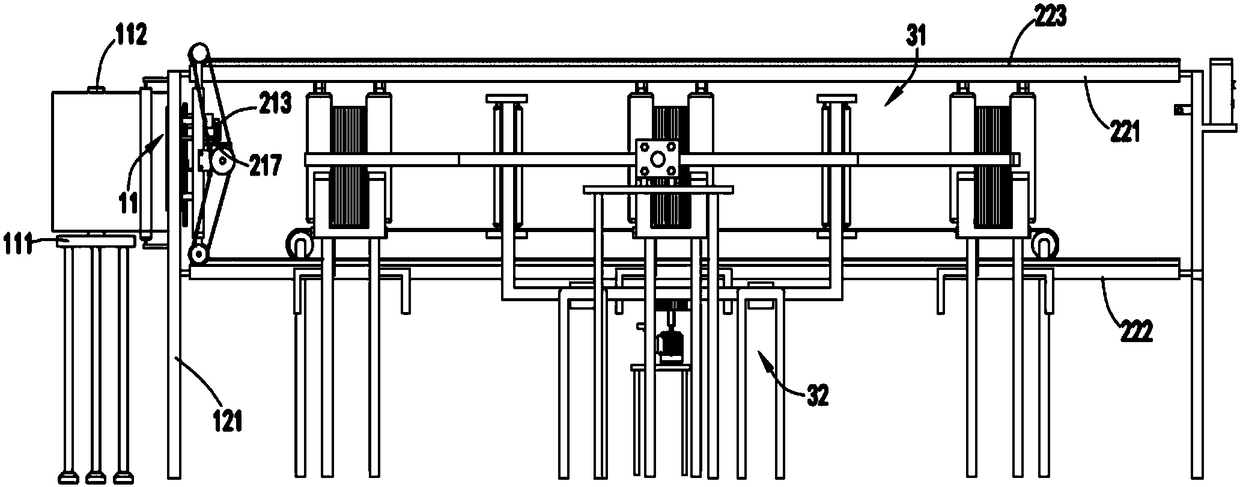

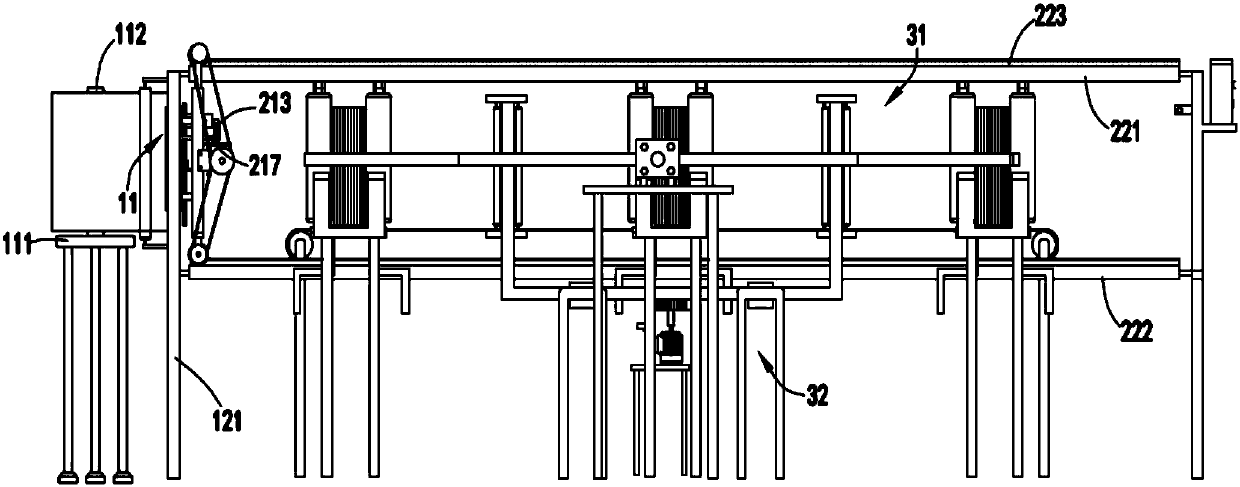

Rapid film wrapping system of battery electrode group

InactiveCN107863548AImprove coating efficiencyGood coating effectFinal product manufactureSecondary cells manufactureEngineeringAutomation

The invention relates to a rapid film wrapping system of a battery electrode group. The system comprises an unreeling device, a film unfolding device, a cutting device and a film wrapping device. Theunreeling device comprises an unreeling mechanism, a positioning mechanism installed on one side of the unreeling mechanism and used for positioning a film end portion, and a transverse cutting mechanism installed on one side of the positioning mechanism. The film unfolding device comprises a guide mechanism, an adsorption mechanism installed on the guide mechanism and performing adsorption on thefilm end portion of the positioning mechanism, and a hauling mechanism used for driving the adsorption mechanism and the film end portion to move along the guide mechanism to unfold a film. The cutting mechanism comprises cutting positioning mechanisms installed on the front side and the rear side of the guide mechanism, and a driving mechanism used for driving the cutting positioning mechanismsto cut the unfolded film at regular intervals. The film wrapping device comprises a material pushing mechanism and a film wrapping mechanism, the material pushing mechanism is used for pushing a to-be-wrapped electrode group to move along the film wrapping mechanism, and cooperating with the film wrapping mechanism to finish the film wrapping. The rapid film wrapping system solves the problems oflow efficiency of the electrode group film wrapping, the difficulty of achieving automation, and low quality of the film wrapping.

Owner:阜阳洁平日化有限公司

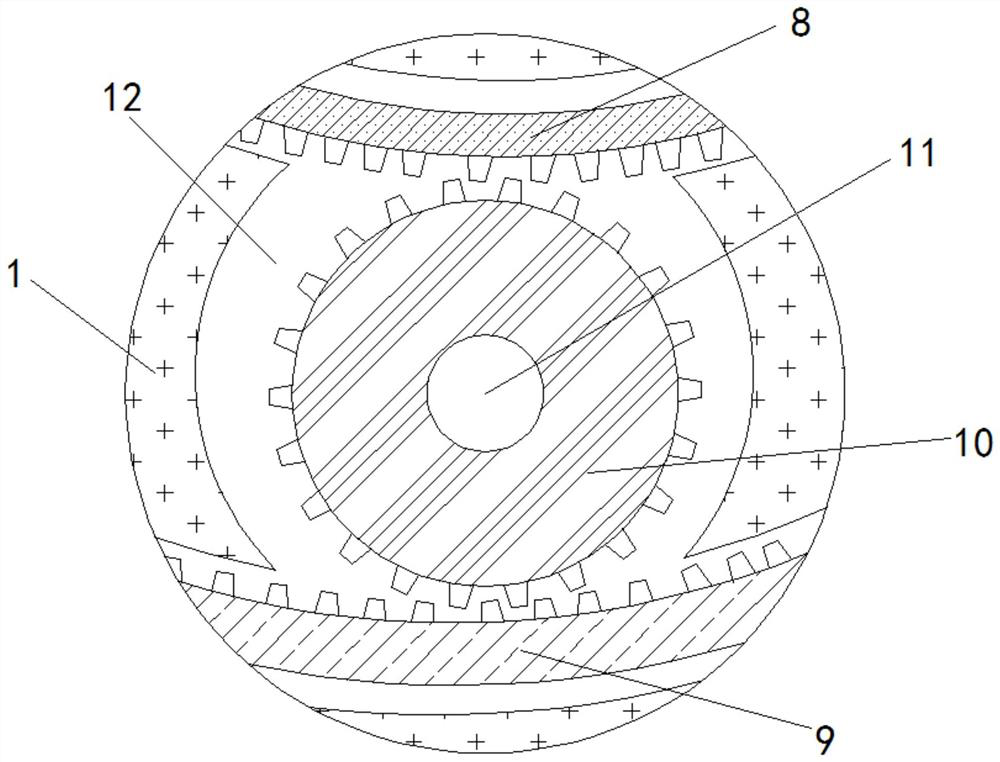

High-precision annular plate bending device

The invention relates to the technical field of plate processing, and discloses a high-precision annular plate bending device which comprises a base. A limiting groove is formed in the middle of the base, a mold is movably connected to the inner wall of the limiting groove, a rotating shaft is movably connected to the middle of the mold, a first adjusting ring is fixedly connected to the left sideof the mold, a dielectric plate is fixedly connected to the inner wall of the middle of the first adjusting ring, a second adjusting ring is fixedly connected to the right side of the mold, and an electromagnet is fixedly connected to the inner wall of the middle of the base. According to the high-precision annular plate bending device, a rotating shaft is adjusted to drive a gear to rotate, thegear drives the first adjusting ring and the second adjusting ring to rotate, the first adjusting ring drives the dielectric plate to move, and then a positive plate and a negative plate are used in cooperation, so that the effect of adjusting the angle of the mold is achieved; and the mold shrinks towards inside under the action of the rotating shaft, the included angle between the molds is reduced, the dielectric plate rotates along with the first adjusting ring, and when the dielectric plate rotates to the position between the positive plate and the negative plate, a piezoresistor is triggered to work.

Owner:赵东

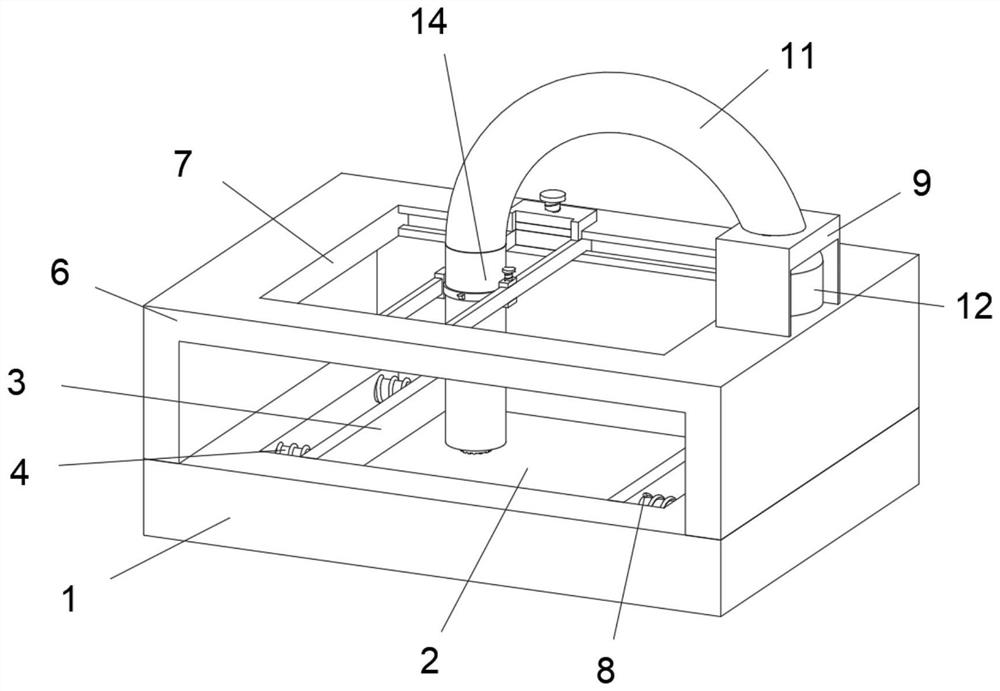

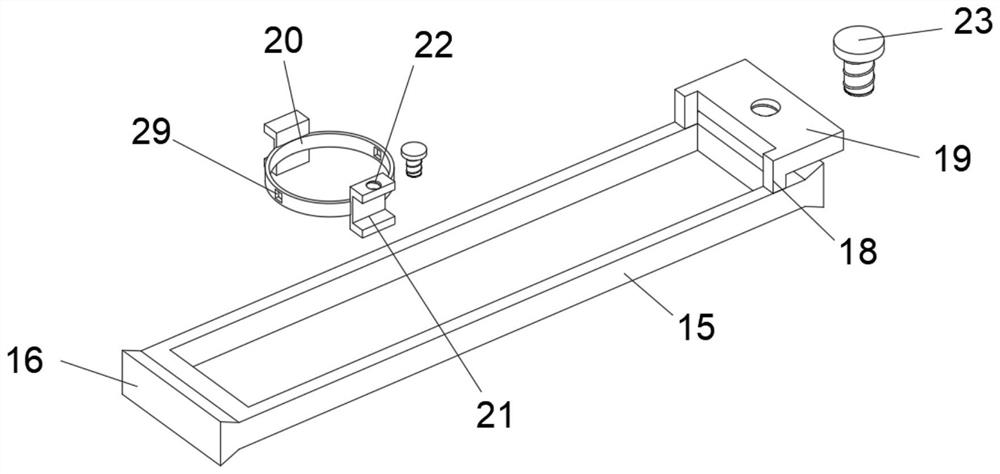

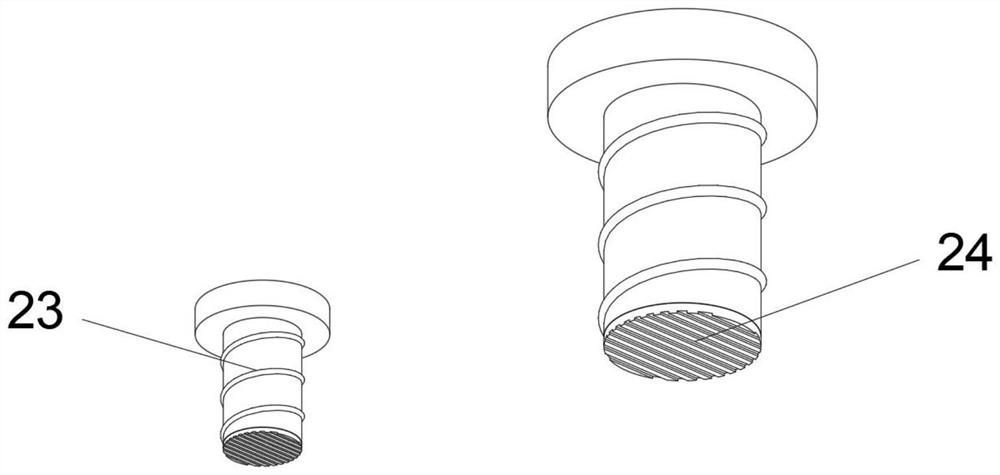

Chip sample delayering grinding method

InactiveCN112872918AImprove effectivenessAvoid confusionPreparing sample for investigationLapping machinesTest analysisEngineering

The invention discloses a chip sample delayering grinding method, and belongs to the field of chip test and analysis. The chip sample delayering grinding method is implemented based on a chip sample grinding device. The chip sample grinding device comprises a base, wherein a supporting frame is arranged on the upper side of the base, a through groove is formed in the position, opposite to a chip groove, of the middle of the top face of the supporting frame, a fixing box is arranged on the right side of the top face of the supporting frame, a threaded hole is formed in the middle of the top face of the fixing box, a metal hose is connected with the upper end of the threaded hole, a collecting bottle is arranged in the fixing box, external threads are arranged on the outer wall of the open end of the collecting bottle, a filter screen is embedded in the middle of the bottom face of the collecting bottle, and a fixed-point sampling assembly is arranged below the left side of the metal hose. In this way, the accuracy of the grinding sampling work of the fault area of the chip is improved, samples in other areas are prevented from being mixed with the sample, the effectiveness of analysis results is improved, and great help is provided for workers to analyze the cause of the fault of the chip.

Owner:吴碧云

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com