Rapid film wrapping system of battery electrode group

A battery pole group and fast packaging technology, which is applied in the direction of lead-acid battery, secondary battery manufacturing, lead-acid battery construction, etc., can solve the problems of difficulty in automation, low efficiency of pole group coating, and poor quality of coating, and achieve Ingenious structure, manpower saving and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

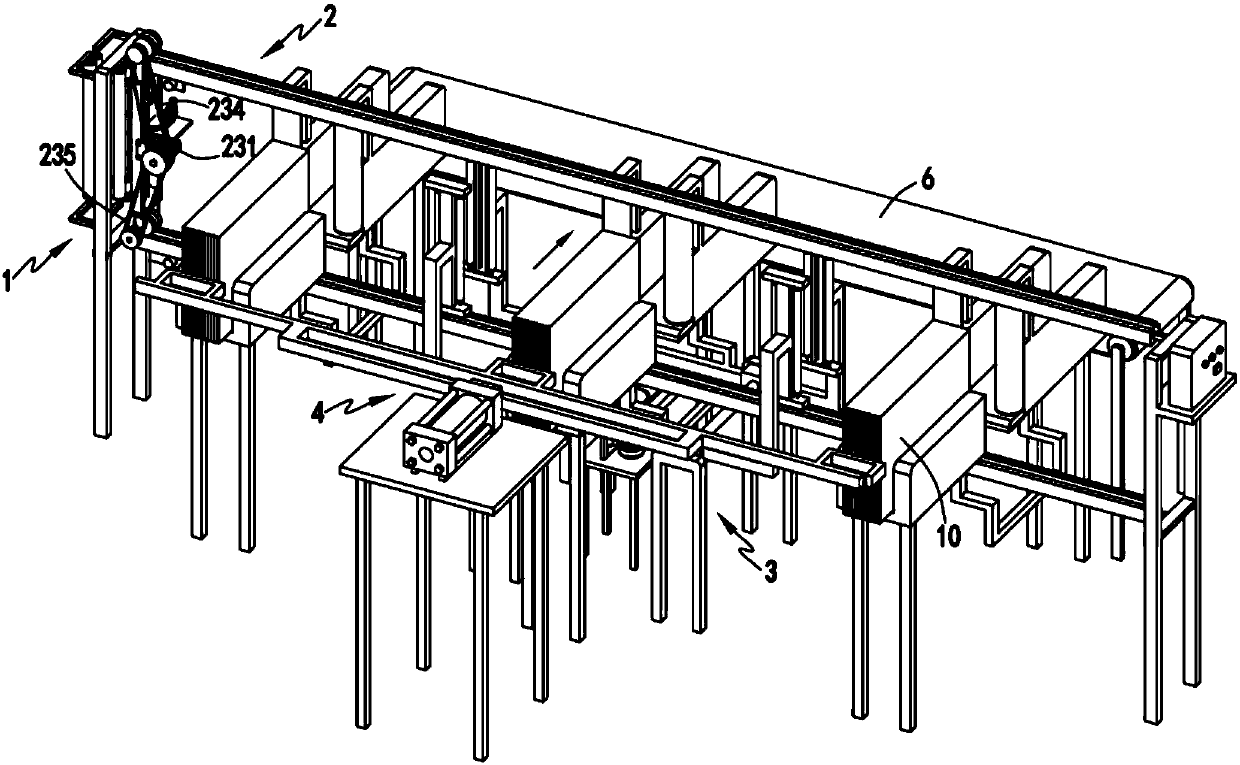

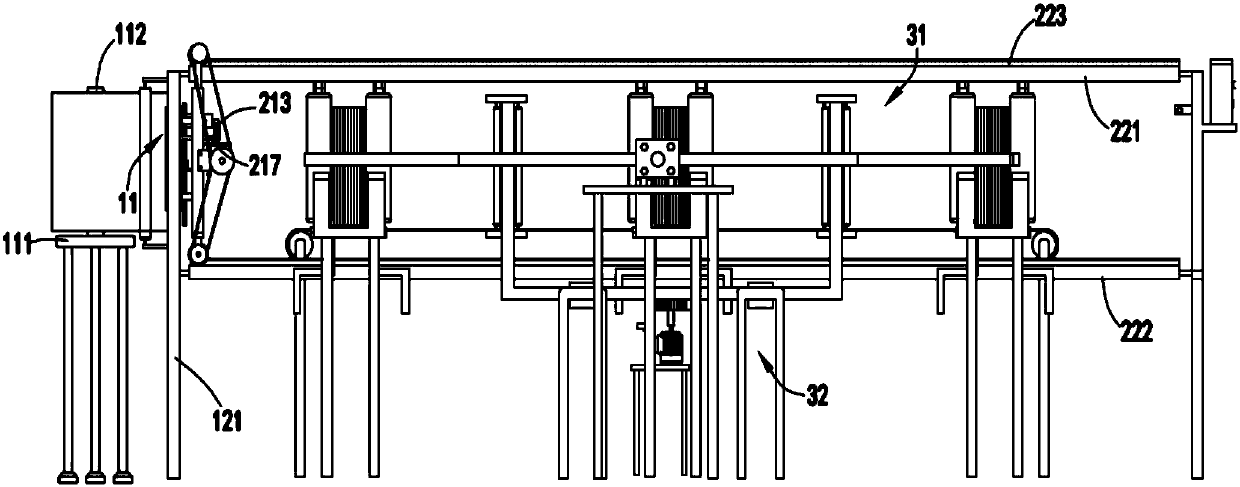

[0050] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 As shown, a battery pole group rapid coating system includes an unwinding device 1, and the unwinding device 1 includes an unwinding mechanism 11 for placing a roll film, and an unwinding mechanism 11 arranged on one side of the unwinding mechanism 11. A positioning mechanism 12 for positioning the end of the roll film and a cross-cutting mechanism 13 arranged on one side of the positioning mechanism 12;

[0051] The film unrolling device 2, the film unrolling device 2 includes a guide mechanism 22, an absorbing mechanism 21 arranged on the guide mechanism 22 for absorbing the end of the roll film at the positioning mechanism 12 and for driving the absorbing mechanism 21, together with the end of the roll film, moves along the guide mechanism 22 to the traction mechanism 23 that unfolds the film;

[0052] A cutting device 3, which includes a cutting p...

Embodiment 2

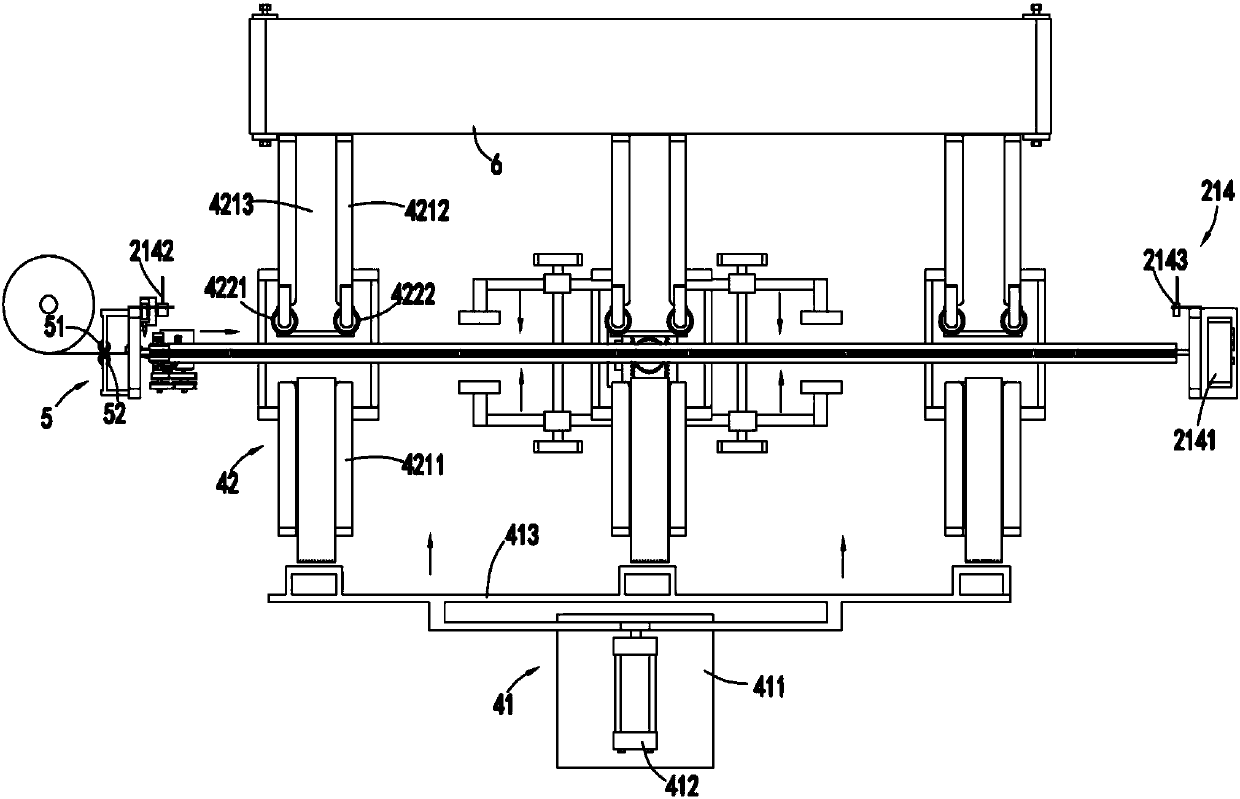

[0072] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that further, the cutting positioning mechanism 31 includes a sliding seat 311, a cutting positioning assembly a312 which is slidably arranged on the sliding seat 311 and symmetrically arranged front and rear, and a cutting positioning component b313;

[0073] The cutting positioning assembly a312 includes a slider a3121 that cooperates with the guide rod b3111 on the sliding seat 311 to slide, a connecting frame a3122 fixedly connected to the sliding block a3121, a mounting frame a3123 arranged at the end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com