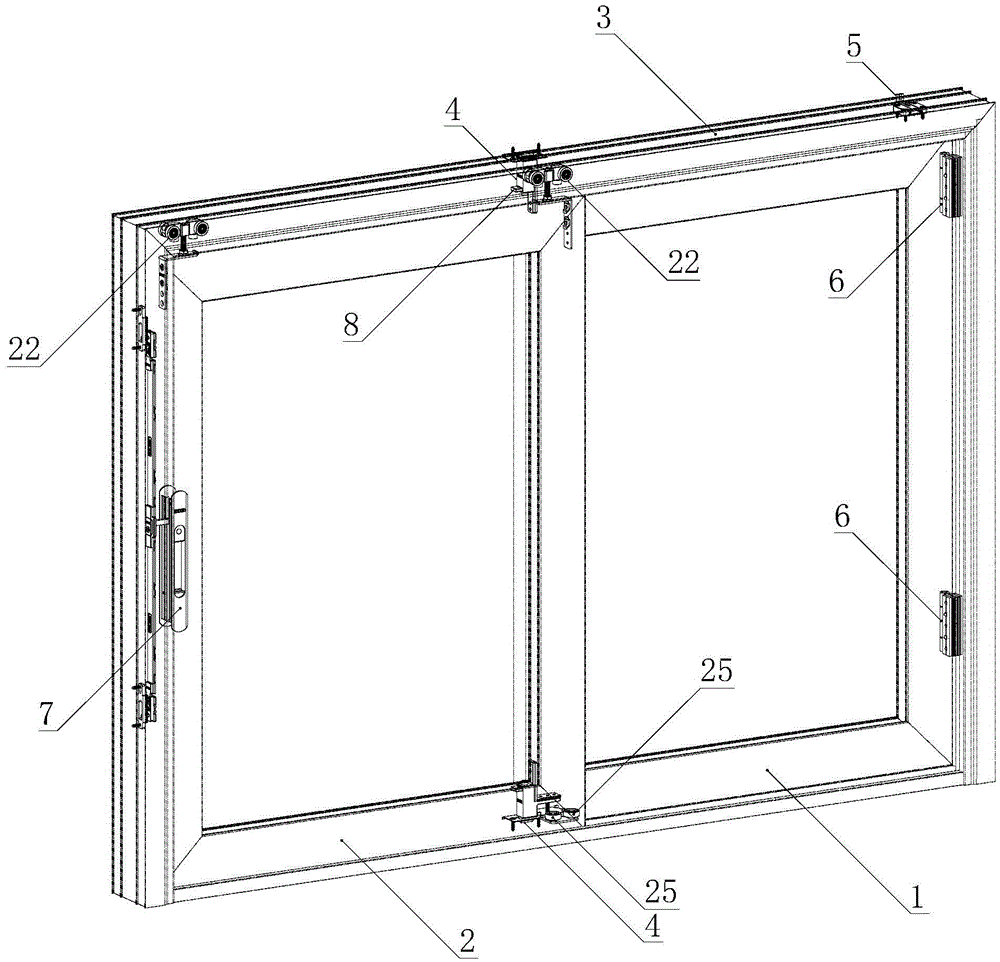

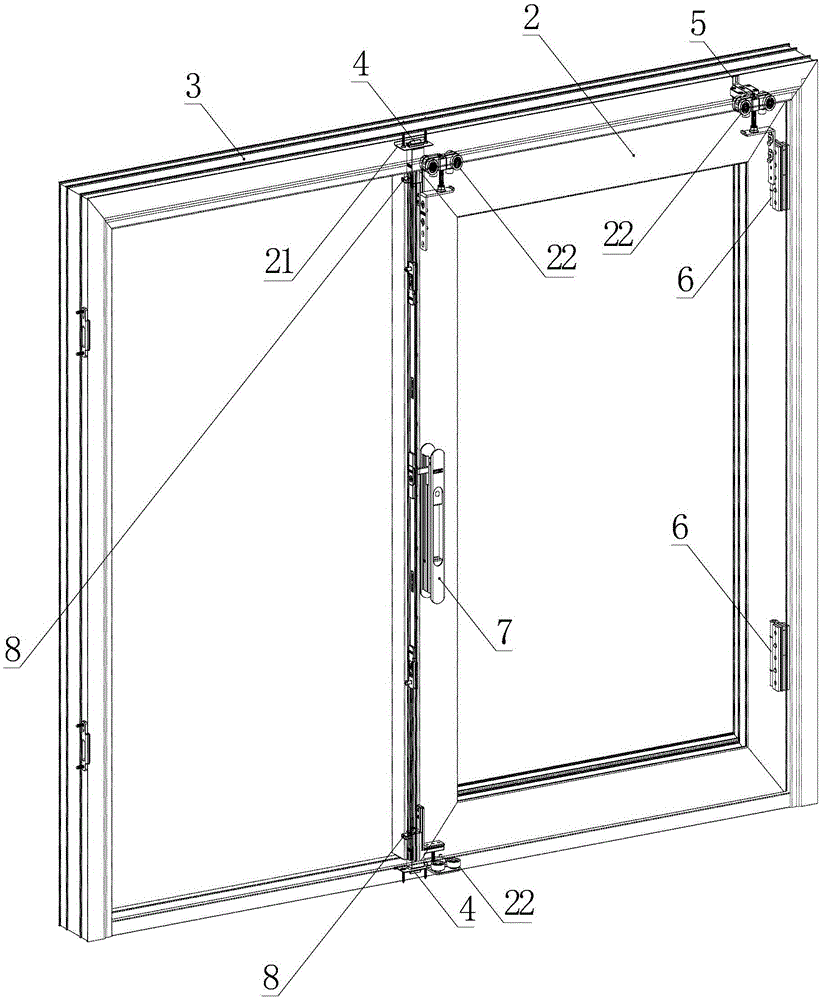

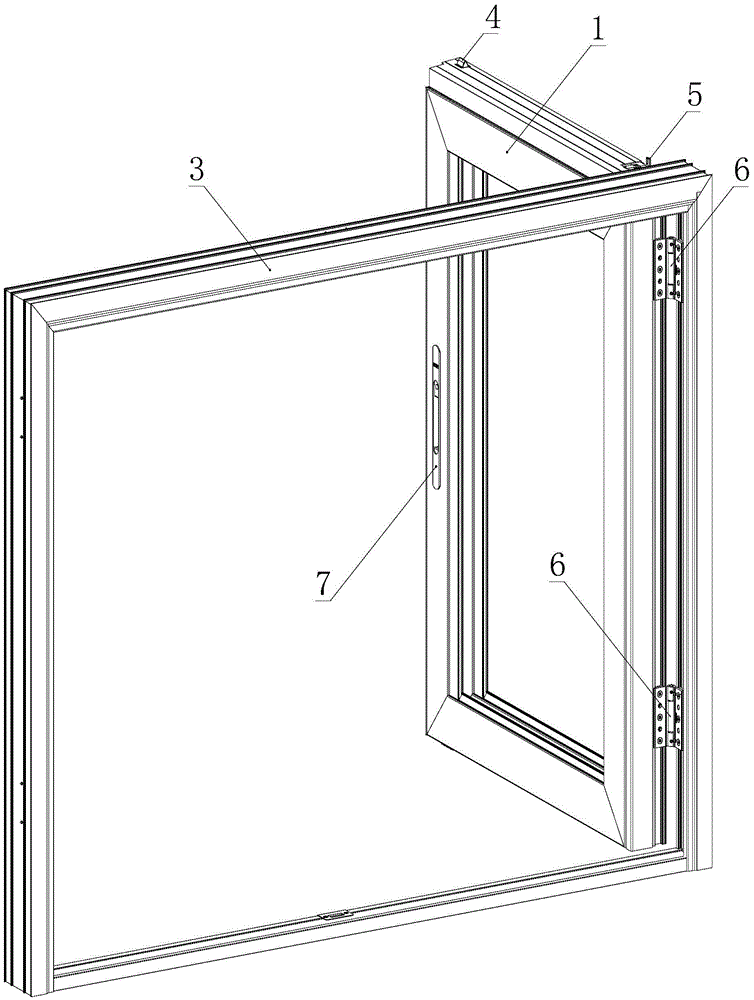

Automatic positioning lock and anti-misoperation sliding casement door and window hardware system and method

A technology for preventing misoperation and pushing and pulling doors and windows, which is applied to the layout of windows/doors, building locks, and wing leaves, etc., and can solve problems such as inability to realize automatic positioning, locking and/or anti-misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Embodiment 1, the anti-misoperation automatic locking device 4 also includes a first spring 12, the anti-misoperation contact block 8 is arranged on the housing 9 through the first spring 12, and the limit position of the anti-misoperation contact block 8 is the first The position where the spring 12 is naturally opened, and the non-limit position is the position after the first spring 12 is compressed (as an alternative embodiment of the embodiment, the anti-misoperation contact block 8 is arranged on the housing 9 through the first spring 12, and the anti-misoperation The limiting position of the misoperation contact block 8 is the position after the first spring 12 is compressed, and the non-limiting position is the position where the first spring 12 is naturally opened. Such a person skilled in the art knows that the replacement of the usual means can also be realize the technical scheme of the claims of the present invention).

[0064] Further, the anti-misoperatio...

Embodiment 2

[0080] The anti-misoperation limiting device 5 also includes a third spring 31, and the anti-misoperation L-shaped column 26 is arranged on the anti-misoperation fixed seat 27 by the third spring 31, and the position limiting position of the anti-misoperation L-shaped column 26 is the first The natural loose position of three springs 31, the non-limiting position of anti-misoperation L-shaped post 26 is the compression position when the third spring 31 is compressed (as the implementation mode that embodiment replaces, anti-misoperation L-shaped post 26 can not adopt the first Three springs 31 are directly controlled by manual mode, or the anti-misoperation L-shaped column 26 slides on the anti-misoperation fixing seat 27 through the transmission lever to realize the switching between the limit position and the non-limit position); when adopting the third For the spring 31, in a preferred embodiment, the number of the third spring 31 is two, and the third spring 31 can be made ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com