Intermittent-type carrying device with limiting function

A transportation device and intermittent technology, which is applied in the direction of transportation and packaging, transportation of passenger cars, railway car body parts, etc., can solve problems such as energy waste, and achieve the effect of reducing energy waste and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

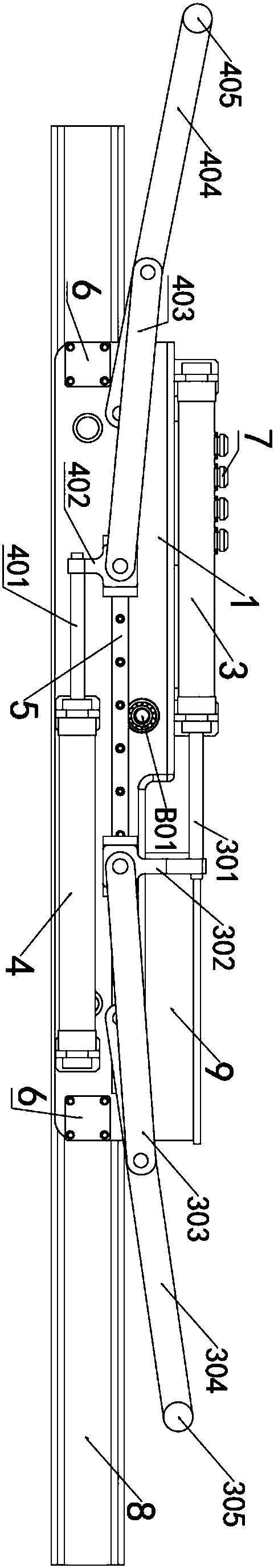

[0041] Such as figure 1 and Figure 4 As shown, a position-limiting intermittent transport device includes a car body 1 and a transport track 8, and is characterized in that the lower end of the car body 1 is provided with a walking chamber 2 used in conjunction with the transport track 8, and the car body A first pushing mechanism for pushing or braking the bogie is fixed on the body 1 . 1

[0042] Further, the first pushing mechanism includes a first hydraulic cylinder 3 fixed on the vehicle body 1, a sliding arm 5 and a first slider crank mechanism, and the first slider crank mechanism includes a first slider 302, a second A sliding rod 303, a first rotating rod 304 and a first push block 305, the first sliding block 302 is connected to the rod end of the first hydraulic rod 301 of the first hydraulic cylinder 3, and the first sliding block 302 covers Set on the sliding arm 5, one end of the first sliding rod 303 is connected to the first slider 302, and the other end of...

Embodiment 2

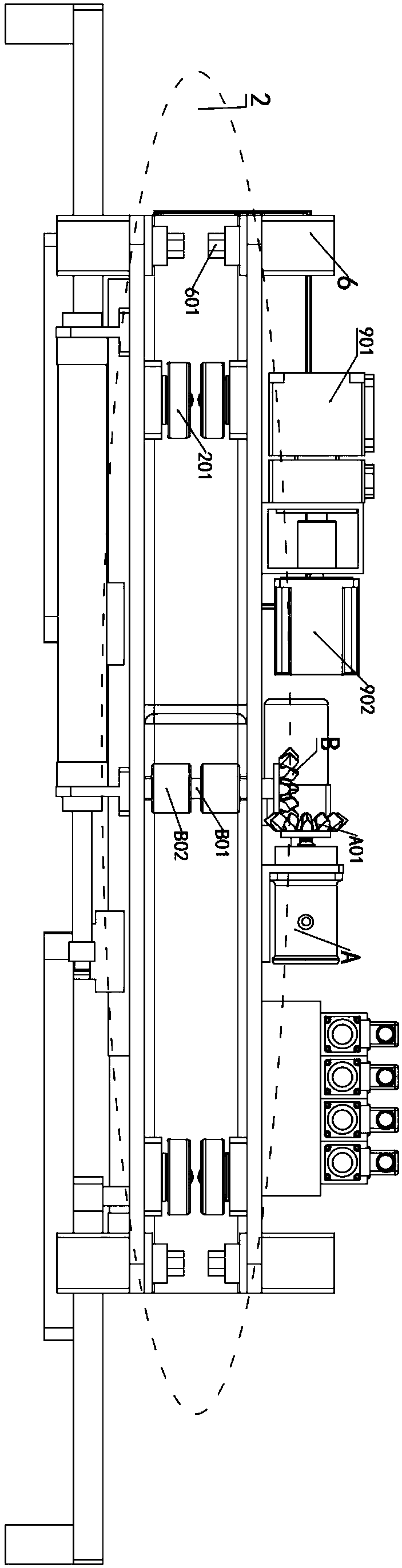

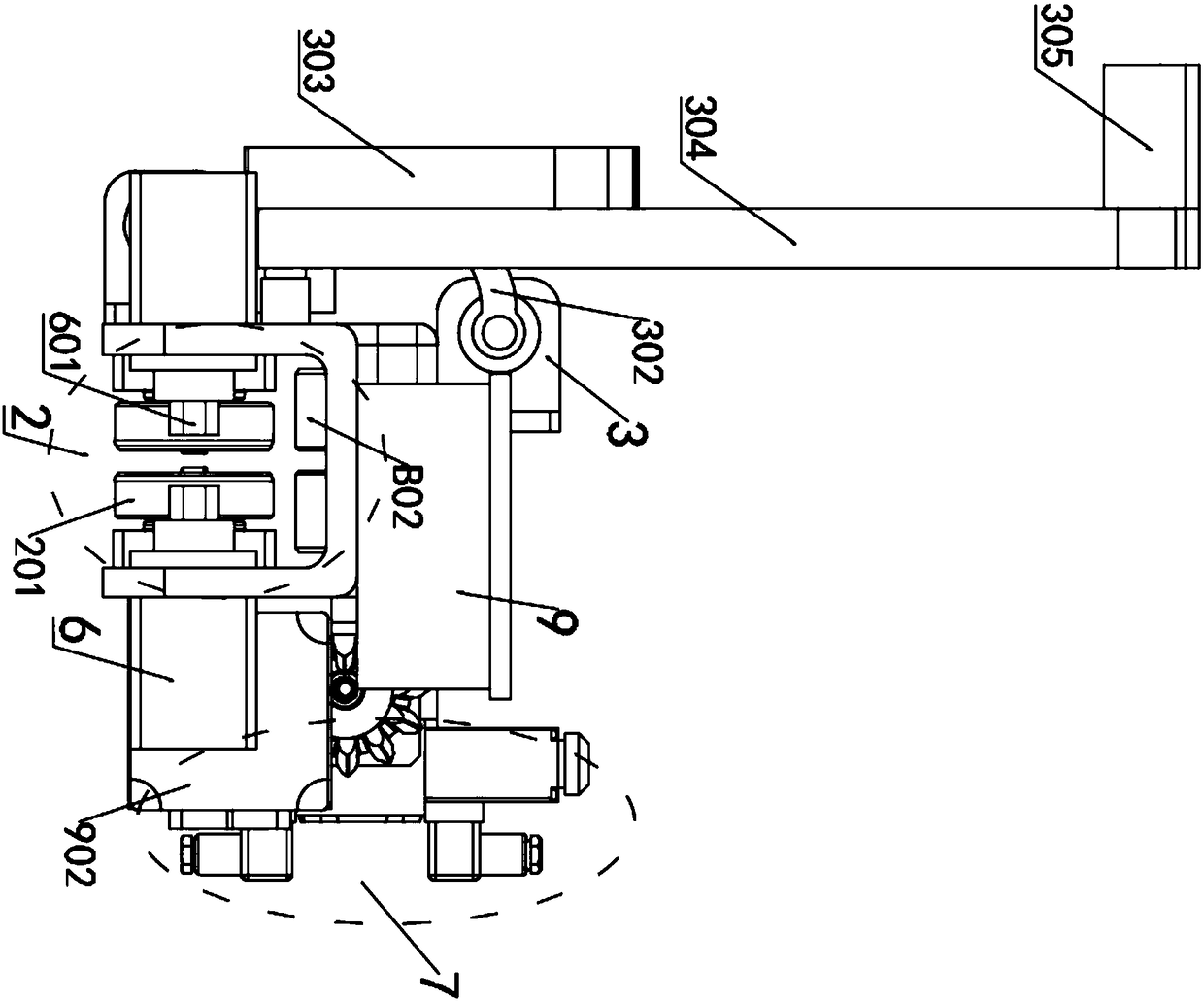

[0050] Such as figure 2 , image 3 and Figure 6 As shown, this embodiment is further optimized on the basis of Embodiment 1. Specifically, the transportation track 8 is set as an "I"-shaped structure, and the transportation track 8 includes a flange plate 801 and a web 802 .

[0051] Further, a driving wheel B02 , a positioning wheel 201 and a brake lever 601 are arranged in the walking chamber 2 , and the driving wheel B02 is arranged in the walking chamber 2 near the upper end.

[0052] Further, the positioning wheels 201 are arranged symmetrically on opposite side walls of the walking cavity 2, and the distance between the two opposite positioning wheels 201 is greater than the thickness of the web 802, and the upper rim of the positioning wheels 201 The distance from the lower rim of the transmission wheel B02 is greater than the thickness of the flange plate 801 .

[0053] Further, the brake rod 601 is symmetrically arranged on the opposite side walls of the walking...

Embodiment 3

[0061] This embodiment is further optimized on the basis of embodiment 2, specifically, the brake 6 is powered by a hydraulic motor.

[0062] More optimally, two transmission wheels B02 , two pairs of positioning wheels 201 and two pairs of brake levers 601 are arranged in the walking chamber 2 .

[0063]More optimally, as Figure 5 As shown, the transmission motor A is connected to the driving wheel C, and the transmission rod B01 is connected to the driven wheel D, and the driving wheel C and the driven wheel D are connected through a transmission belt E to achieve the purpose of transmission.

[0064] When using the transportation device in this embodiment, the hydraulic motor injects hydraulic oil to make the brake lever 601 stretch out and clamp the web 802 of the transportation track 8. Since there is a certain space inside the hydraulic oil, a certain degree of elasticity can be allowed. Deformation, when the brake lever 601 needs a certain movement space, can be reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com