Bending-prevention limiting energy-dissipation supporting component with steel pipe with baffles inside and cross-shaped inward contracting type variable-section steel core

A technology of cross-shaped steel and variable cross-section, which is applied to building components, earthquake resistance, etc., can solve the problems of anti-buckling supports without displacement control devices, etc., and achieve the effects of superior performance, convenient purchase, and complete specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the examples, but the present invention is not limited to the following examples, and the claims shall prevail.

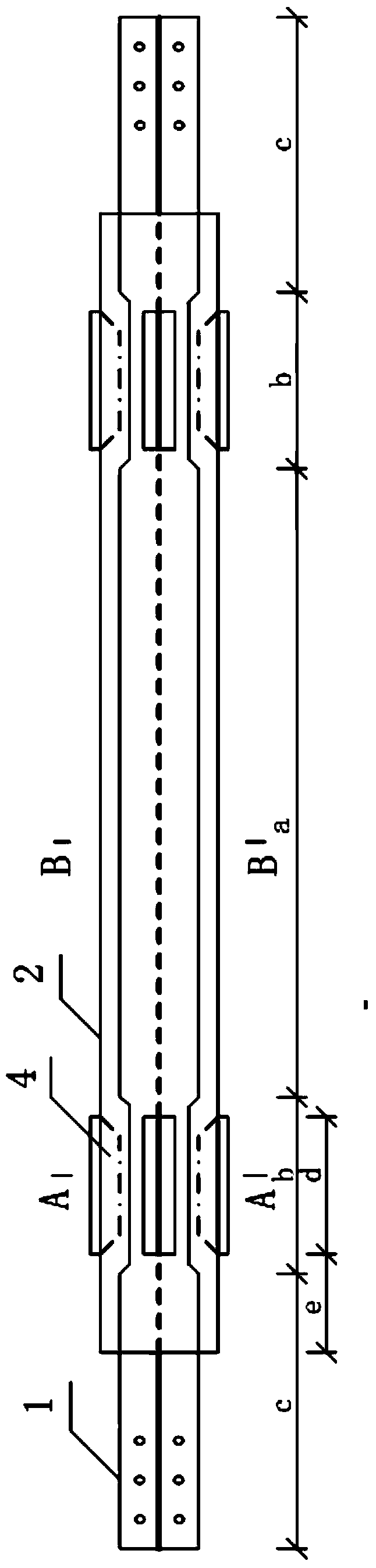

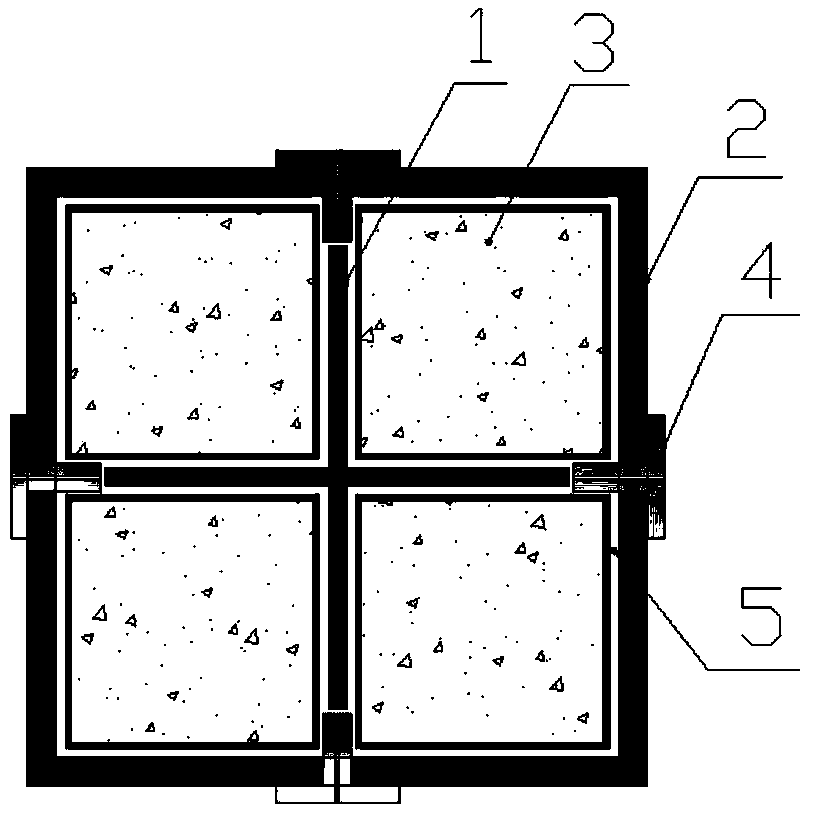

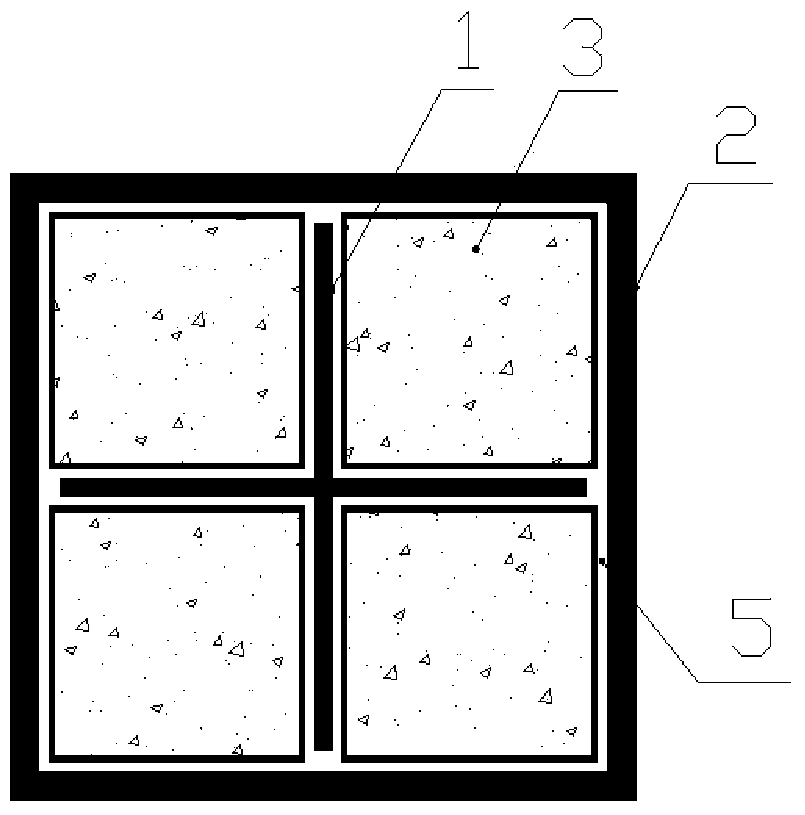

[0023] Such as figure 1 As shown, a baffle-type steel tube cross-shaped retractable variable-section steel core anti-buckling energy-dissipating support member is composed of a cross-shaped steel core (1) and an external restraint steel tube (2). It is characterized in that the cross-shaped steel core (1) is located inside the outer restraint steel pipe (2), and the four square areas formed by the outer restraint steel pipe (2) and the cross-shaped steel core (1) are filled with four square thin-walled steel-filled steel pipe concrete (3), the cross-shaped steel core (1) is sequentially composed of a non-variable section section a, a section reduction section b, and a connecting section c from the middle to both ends, the non-variable section section a is located between the two sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com