Bending-prevention limiting energy-dissipation supporting component with steel pipe with baffles inside and I-shaped inward contracting type variable-section inner core

A variable-section, baffle-type technology, used in building components, shock-proof and other directions, can solve the problem of anti-buckling support without displacement control device, etc., to achieve the effect of superior performance, convenient purchase and complete specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

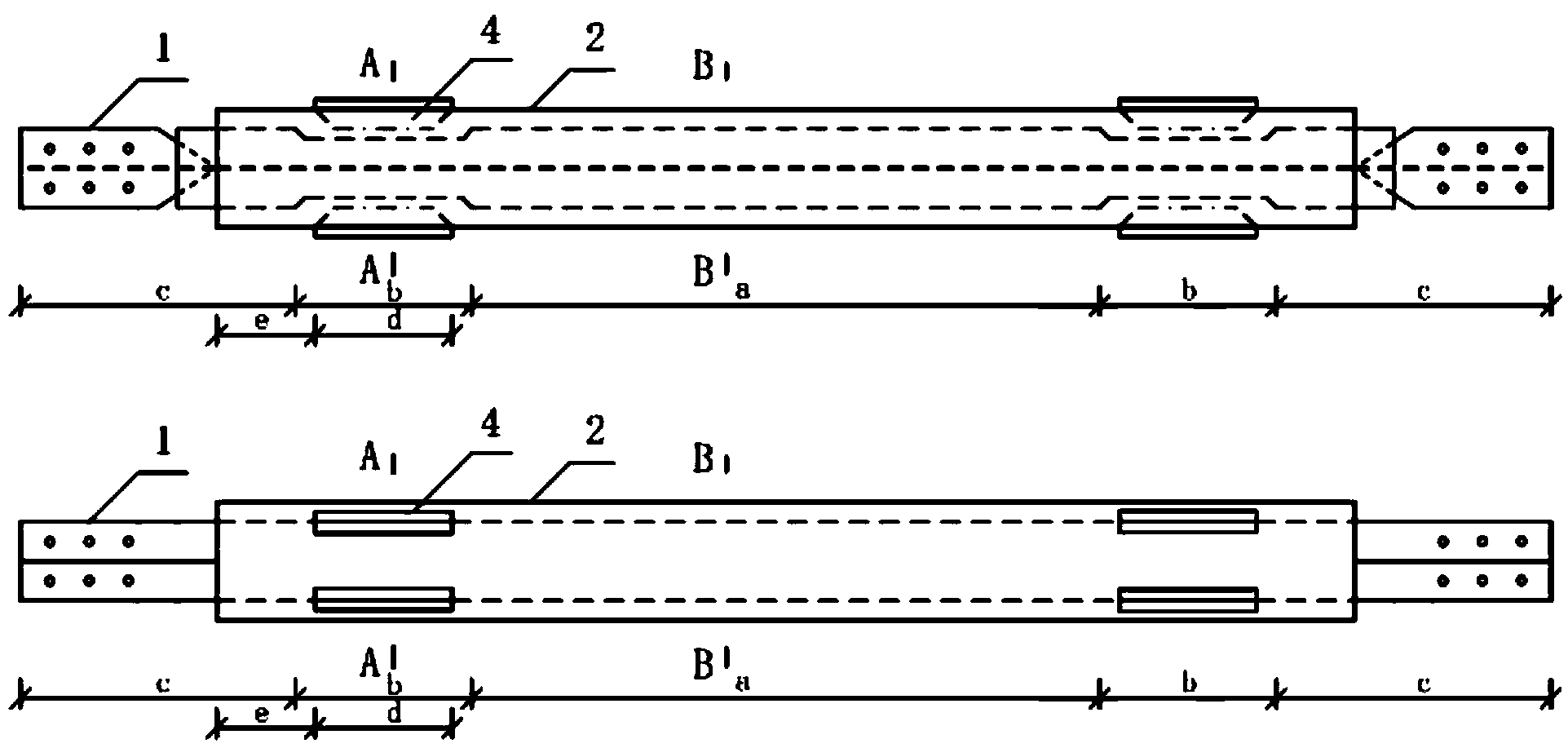

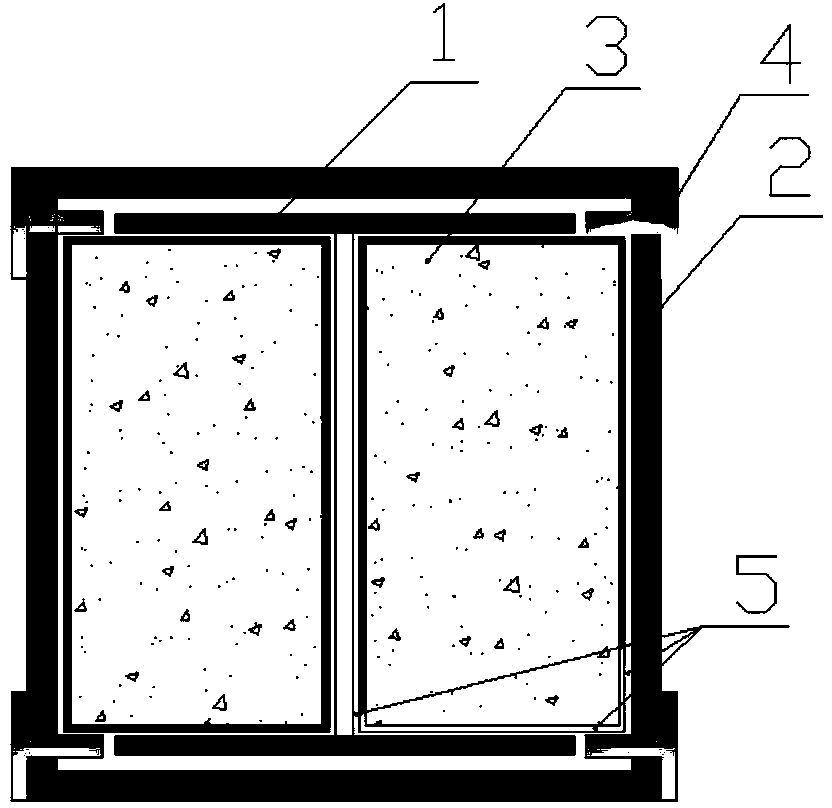

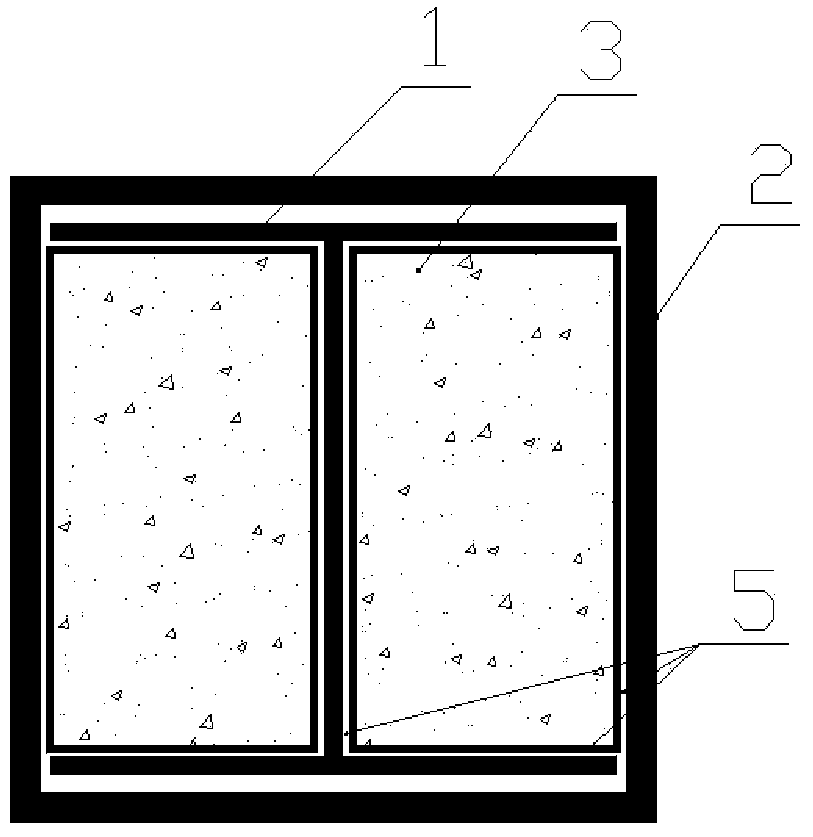

[0019] Such as figure 1 As shown in the figure, a steel tube I-shaped retractable variable cross-section inner core anti-buckling energy-dissipating support member with internal baffles is composed of an I-shaped energy-dissipating steel core (1) and an outer constrained steel tube (2). The outer steel tube Size 300×300mm. The I-shaped energy-dissipating steel core (1) includes a non-variable section section a, a partially reduced section section b, and a connecting section c. Two rectangular spaces are formed between the I-shaped steel core (1) and the outer constraint steel pipe (2) to place two thin-walled steel-filled steel pipe concrete (3). The outer restraint steel pipe (2) is a square steel pipe with grooves on two sides, and the diameter of the outer restraint steel pipe (2) is slightly larger than the diameter of the non-variable section of the core material (1) by about 10mm. The outer restraint steel pipe (2) and the core material A non-adhesive material layer (5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com