Strain insulator string for multi-division transmission line

A technology for strain-resistant insulator strings and transmission lines, which is applied in the direction of suspension/strain insulators, cable suspension devices, etc. It can solve the problems that jumpers cannot be connected in any direction, affect the safe operation of transmission lines, and lead wear, etc., and achieve superior performance. , solve the effect of wear and tear and less power loss in line operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

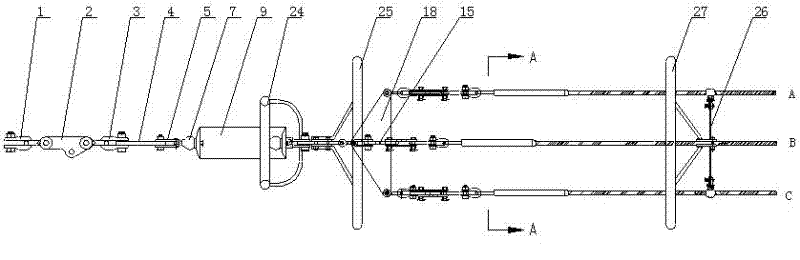

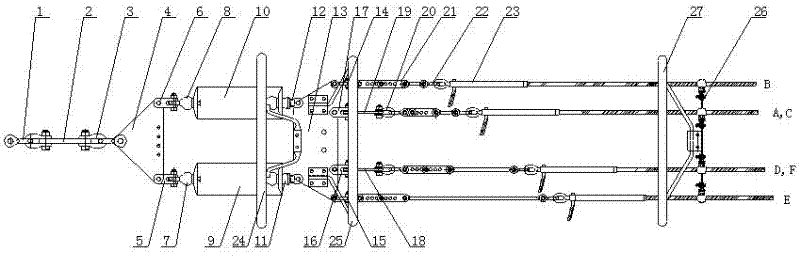

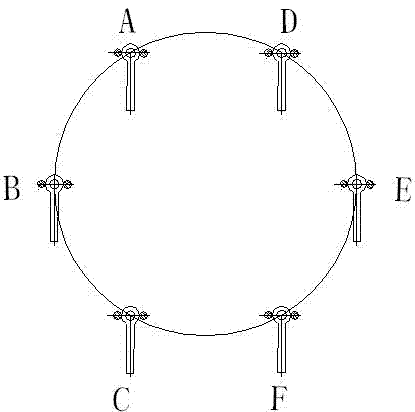

[0017] Such as figure 1 , 2 As shown, the fittings string of the present invention is composed of two U-shaped hanging rings 20 that hang together, an adjustment plate 21, two U-shaped hanging rings 22 that hang together and a strain clamp 23 that are hinged to each other in turn.

[0018] The present invention is provided with two sets of U-shaped hanging rings 1 that are hung together. The left end of the two sets of U-shaped hanging rings 1 can be hinged with the connecting tower hardware, and the right end is hinged with one end of the traction plate 2. The traction plate The other end of 2 is hinged with one end of another group of two U-shaped hanging rings 3 that are hung together; Hinged, the other end of the two connecting plates 4 are respectively hinged two right-angle hanging plates 5,6.

[0019] The other end of the right-angle hanging plate 5 is hinged with a ball link 7, and the other end of the ball link 7 is hinged with an insulator 9; the other end of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com