Preparation method of low-hydroxymethyl melamine formaldehyde resin

A technology of methylol melamine and formaldehyde resin, which is applied in the field of preparation of low methylol melamine formaldehyde resin, can solve the problems of restricting large-scale application, bottleneck of industrialization scale, poor resin stability, etc., and achieve good stability and performance Superior, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: the preparation of low methylol melamine formaldehyde resin

[0029] (1) Mix melamine and formaldehyde aqueous solution in a ratio of melamine:formaldehyde aqueous solution of 9:20 by weight, adjust the pH to 7.8 with NaOH solution, heat up to 80°C and keep it warm for 160 minutes;

[0030] (2) After the reaction is finished, cool down to 50°C, and add melamine: water in a ratio of 9:5 by weight;

[0031] (3) Filtrate to obtain the finished resin product, grouped as No. 1.

Embodiment 2

[0032] Embodiment 2: the preparation of low methylol melamine formaldehyde resin

[0033] (1) Mix melamine and formaldehyde aqueous solution in a ratio of 10:25 by weight of melamine:formaldehyde aqueous solution, adjust the pH to 8.0 with NaOH solution, heat up to 80°C and keep it warm for 160 minutes;

[0034] (2) After the reaction is finished, cool down to 50°C, and add melamine: water in a ratio of 10:6 by weight;

[0035] (3) Filtrate to obtain the finished resin product, grouped as No. 2.

Embodiment 3

[0036] Embodiment 3: the preparation of low methylol melamine formaldehyde resin

[0037] (1) Mix melamine and formaldehyde aqueous solution in a ratio of melamine:formaldehyde aqueous solution of 15:35 in parts by weight, adjust the pH to 8.5 with NaOH solution, heat up to 75°C and keep it warm for 180 minutes;

[0038] (2) After the reaction is finished, cool down to 50°C, and add melamine: water in a ratio of 15:8 by weight;

[0039] (3) Filtrate to obtain the finished resin product, grouped as No. 3.

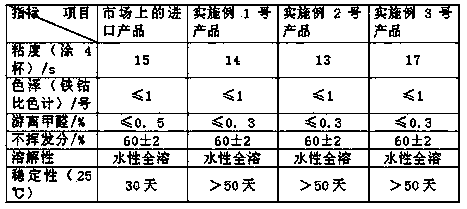

[0040] The product performance indexes of the above-mentioned embodiments are compared in Table 1.

[0041] Table 1 performance index table of each embodiment

[0042]

[0043] As can be seen from the above indicators, the indicators of the low methylol melamine formaldehyde resin prepared by the embodiments of the present invention have better or the same performance as the imported products, and can be effectively preserved, reducing the cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com