Construction method for enhancing structural strength of joint cement concrete pavement

A cement concrete and pavement structure technology, applied in roads, roads, road repairs, etc., can solve the problems of high cost and inability to effectively reduce reflection cracks, and achieve the effect of reducing the thickness of the road surface, good load transfer performance, and reducing reflection cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

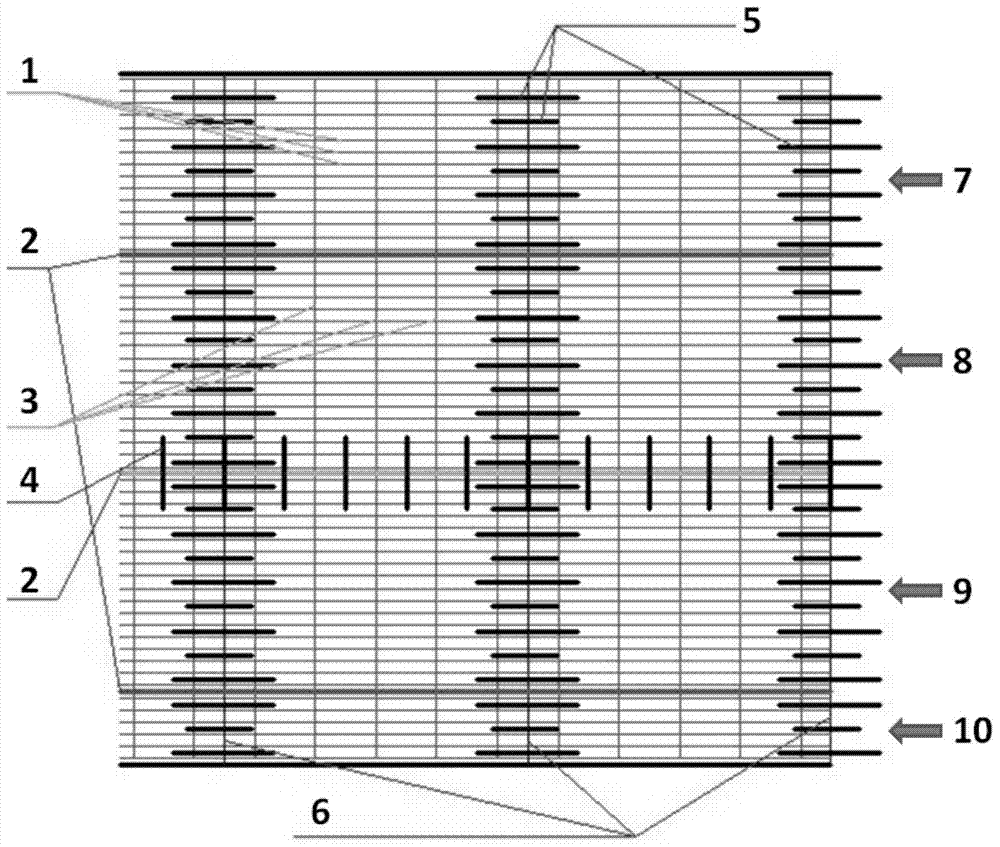

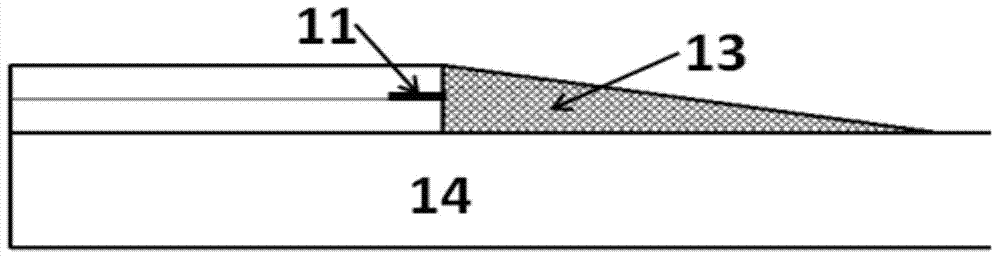

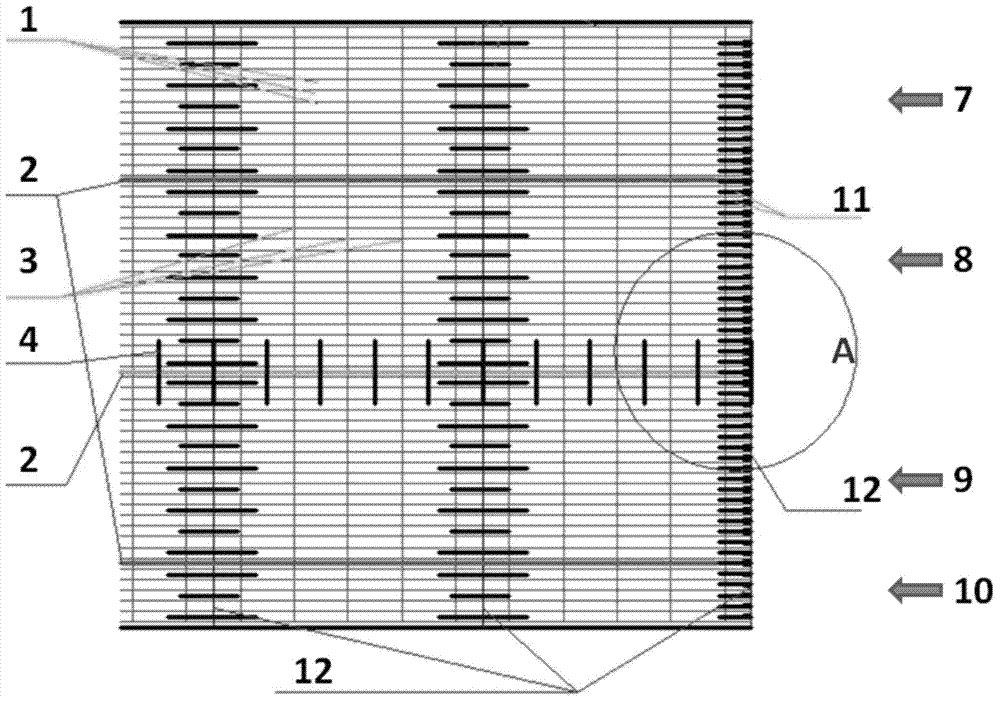

[0041] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the construction method of enhancing the structural strength of joint cement concrete pavement, the construction steps are as follows:

[0042] Step (1), determine the unstable pavement slab in the repaired road section according to the joint load transfer capacity and maximum deflection value:

[0043] The joint load transfer capacity and deflection value are detected and determined by the drop weight deflection meter. The joint load transfer coefficient is less than 40% or the unstable pavement slab with a deflection value greater than 0.89mm when the design load is 100kN needs to be repaired ; The calculation method of load transfer coefficient is as follows:

[0044] k j =(w u / w l )×100

[0045] where k j is the joint load transfer coefficient, (%); w u is the deflection value at the edge of the unloaded plate joint, (0.01mm); w l is the deflection value at the edge of the joint of the load...

Embodiment 2

[0057] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the construction method of enhancing the structural strength of joint cement concrete pavement, the construction steps are as follows:

[0058] Step (1), determine the unstable pavement slab in the repaired road section according to the joint load transfer capacity and maximum deflection value:

[0059] The joint load transfer capacity and deflection value are detected and determined by the drop weight deflection meter. The joint load transfer coefficient is less than 40% or the unstable pavement slab with a deflection value greater than 0.89mm when the design load is 100kN needs to be repaired ; The calculation method of load transfer coefficient is as follows:

[0060] k j =(w u / w l )×100

[0061] where k j is the joint load transfer coefficient, (%); w u is the deflection value at the edge of the unloaded plate joint, (0.01mm); w l is the deflection value at the edge of the joint of the load...

Embodiment 3

[0073] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the construction method of enhancing the structural strength of joint cement concrete pavement, the construction steps are as follows:

[0074] Step (1), determine the unstable pavement slab in the repaired road section according to the joint load transfer capacity and maximum deflection value:

[0075] The joint load transfer capacity and deflection value are detected and determined by the drop weight deflection meter. The joint load transfer coefficient is less than 40% or the unstable pavement slab with a deflection value greater than 0.89mm when the design load is 100kN needs to be repaired ; The calculation method of load transfer coefficient is as follows:

[0076] k j =(w u / w l )×100

[0077] where k j is the joint load transfer coefficient, (%); w u is the deflection value at the edge of the unloaded plate joint, (0.01mm); w l is the deflection value at the edge of the joint of the load...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com