Wire arrangement control method based on servo- moto

A control method and servo motor technology, applied in the direction of electric controllers, etc., can solve the problems of cutting wire radial runout, uneven wire arrangement, and the failure of the wire arrangement device to work normally, and achieve the effect of reducing system cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

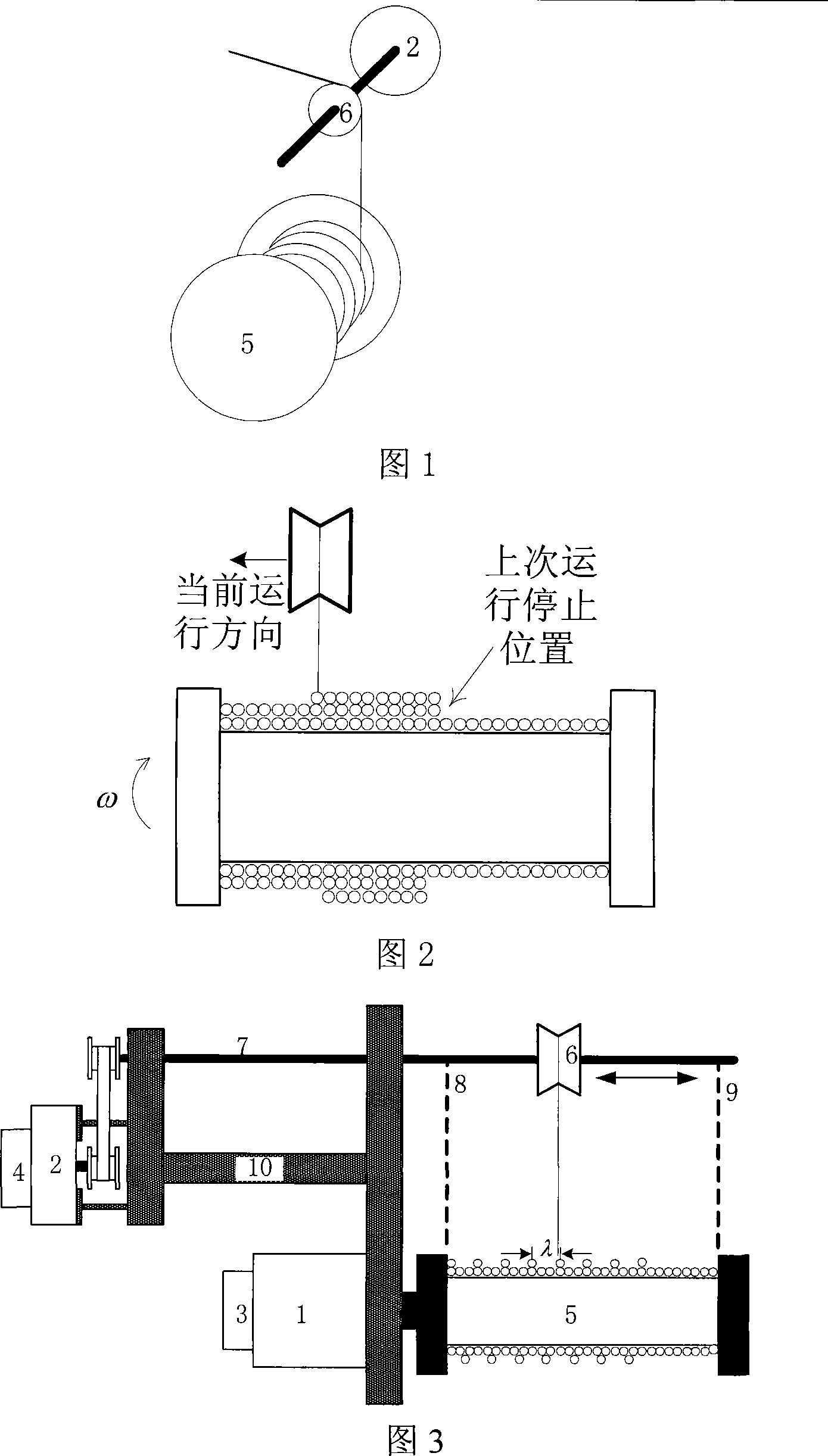

Embodiment Construction

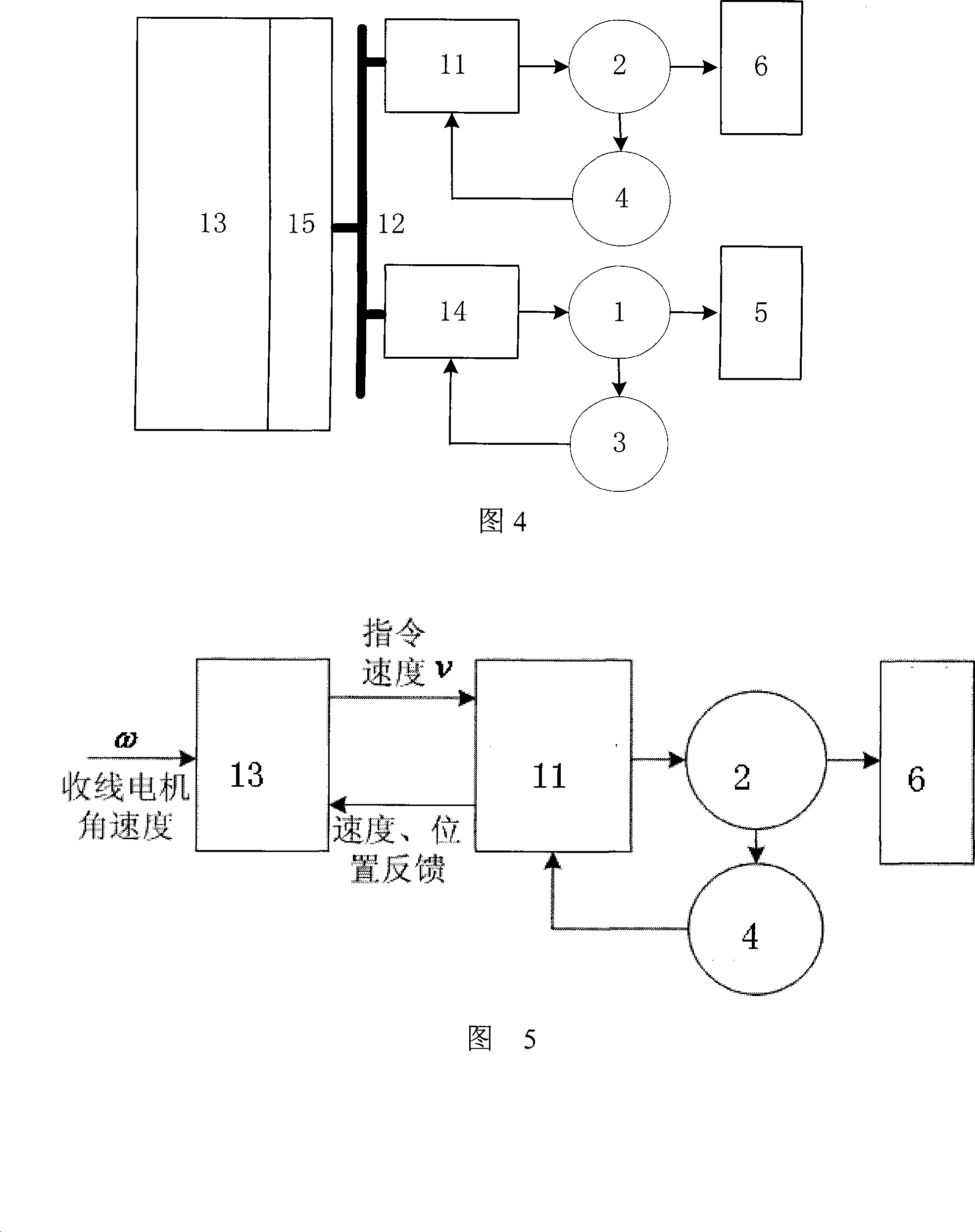

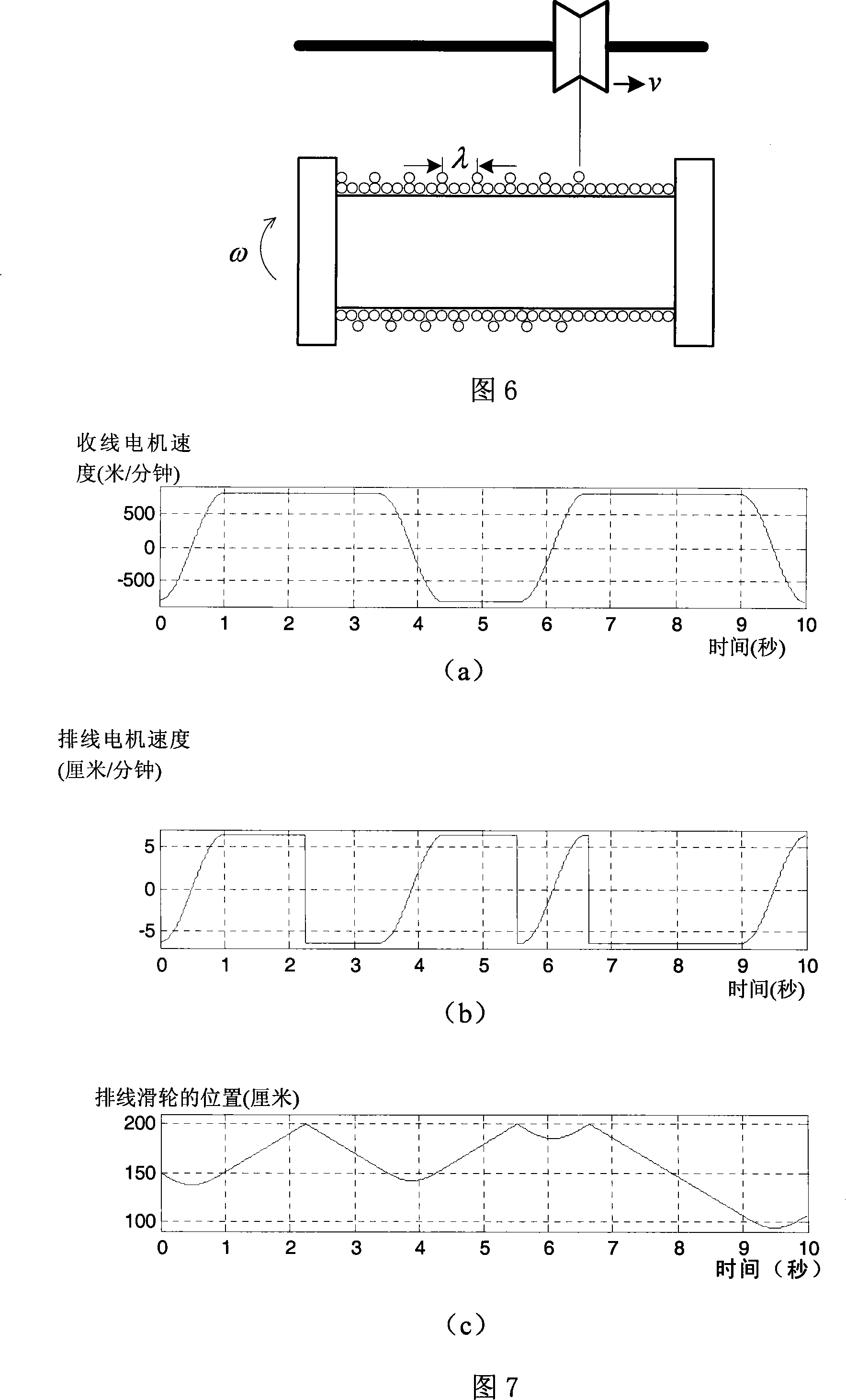

[0053] In order to ensure the accuracy of cable arrangement, in the control device for implementing the servo motor-based cable arrangement control method of the present invention in this embodiment: the motion controller 13 selects the MP2300 motion controller of YASKAWA Company, the take-up motor 1 and the cable arrangement motor 2 The ΣIII type servo driver and ΣII type servo motor of YASKAWA Company are selected. The present embodiment is such as the mechanical structure shown in Fig. 3, and the take-up motor 1 and the wire-discharging motor 2 all adopt AC servo motors, and the speed measuring sensor of the take-up motor 1 selects a 17-bit incremental photoelectric encoder 3 to measure the speed of the take-up motor. The speed sensor of the cable motor 2 uses a 17-bit absolute value photoelectric encoder 4 to feed back the speed and position information of the cable motor in real time. The structure of the control system is shown in Figure 4. Digital communication is carri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com