Box iron grooving type H-shaped variable-cross-section steel core buckling-prevention limiting and energy-consumption supporting component

A technology of I-shaped steel and cross-section, applied in building components, anti-vibration and other directions, can solve the problem of less research on the limiting effect of anti-buckling support, and achieve the effect of superior performance, convenient purchase and complete specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the examples, but the present invention is not limited to the following examples, and the claims shall prevail.

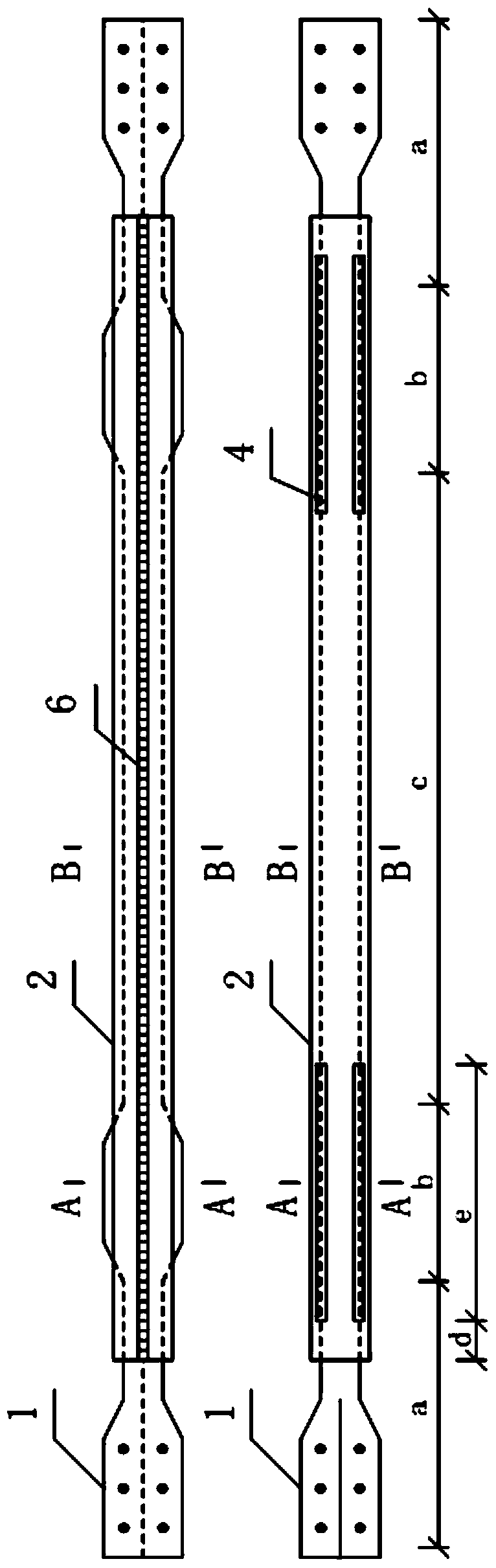

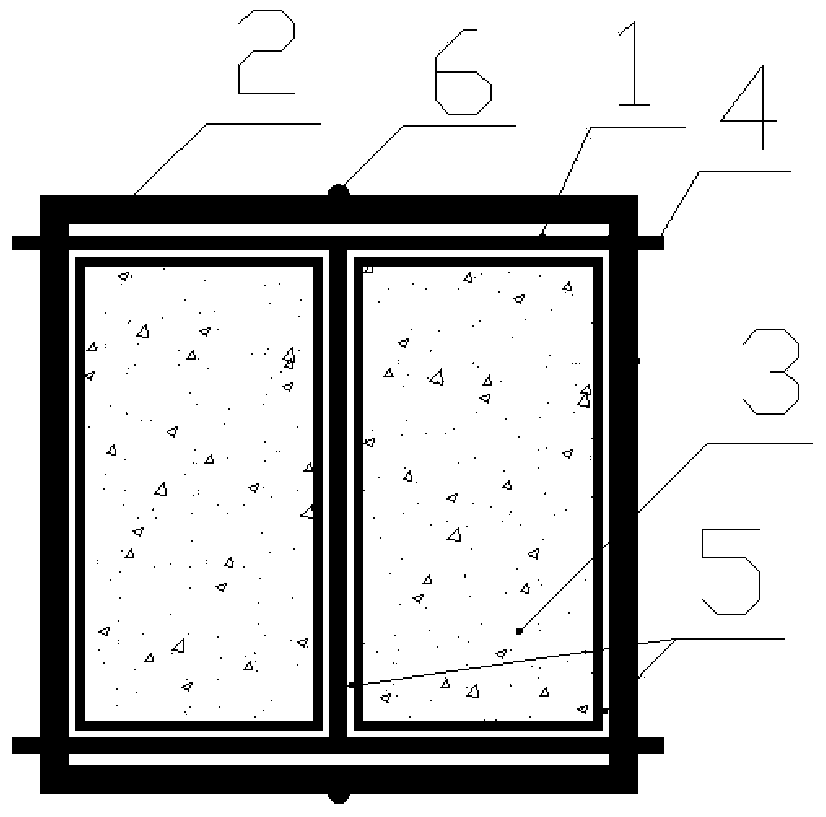

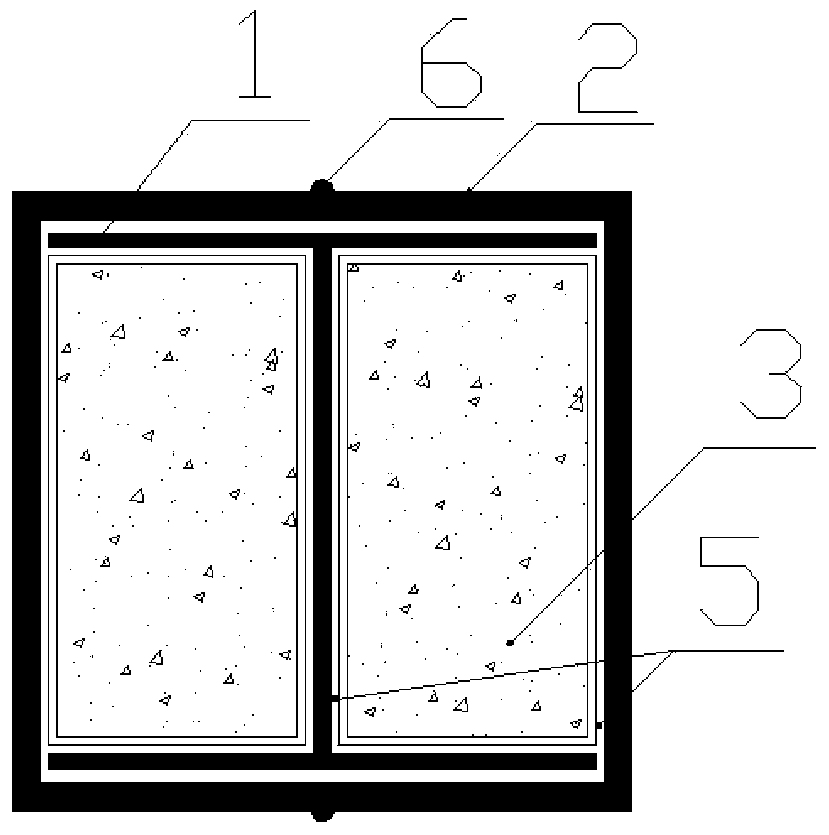

[0022] Such as figure 1 As shown, a channel steel slotted I-shape variable section steel core anti-buckling energy-dissipating support member. It includes an I-shaped steel core (1) and an outer restraint steel pipe (2), and the cross section of the outer restraint steel pipe is 300×300mm. The I-shaped steel core (1) includes a connection section a, a section with a locally enlarged section b, and a yield working section c. The cross section of the I-shaped steel core (1) is partially enlarged at the outer steel pipe limiting groove (4) with a slope angle of 60° until the cross section passes through the outer steel pipe limiting groove (4) by about 30 mm. The two rectangular areas formed between the energy-dissipating steel core (1) and the outer confinement steel pipe (2) are fille...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com