Friction damper capable of achieving variable damping force output

A friction damper and variable damping technology, used in bridge parts, building components, bridges, etc., can solve the problems of inability to meet the requirements of shock absorption, energy dissipation, and single damping force output, and achieve strong energy dissipation capacity and stable hysteresis. Curve, uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0025] The invention provides a friction damper capable of realizing variable damping force output.

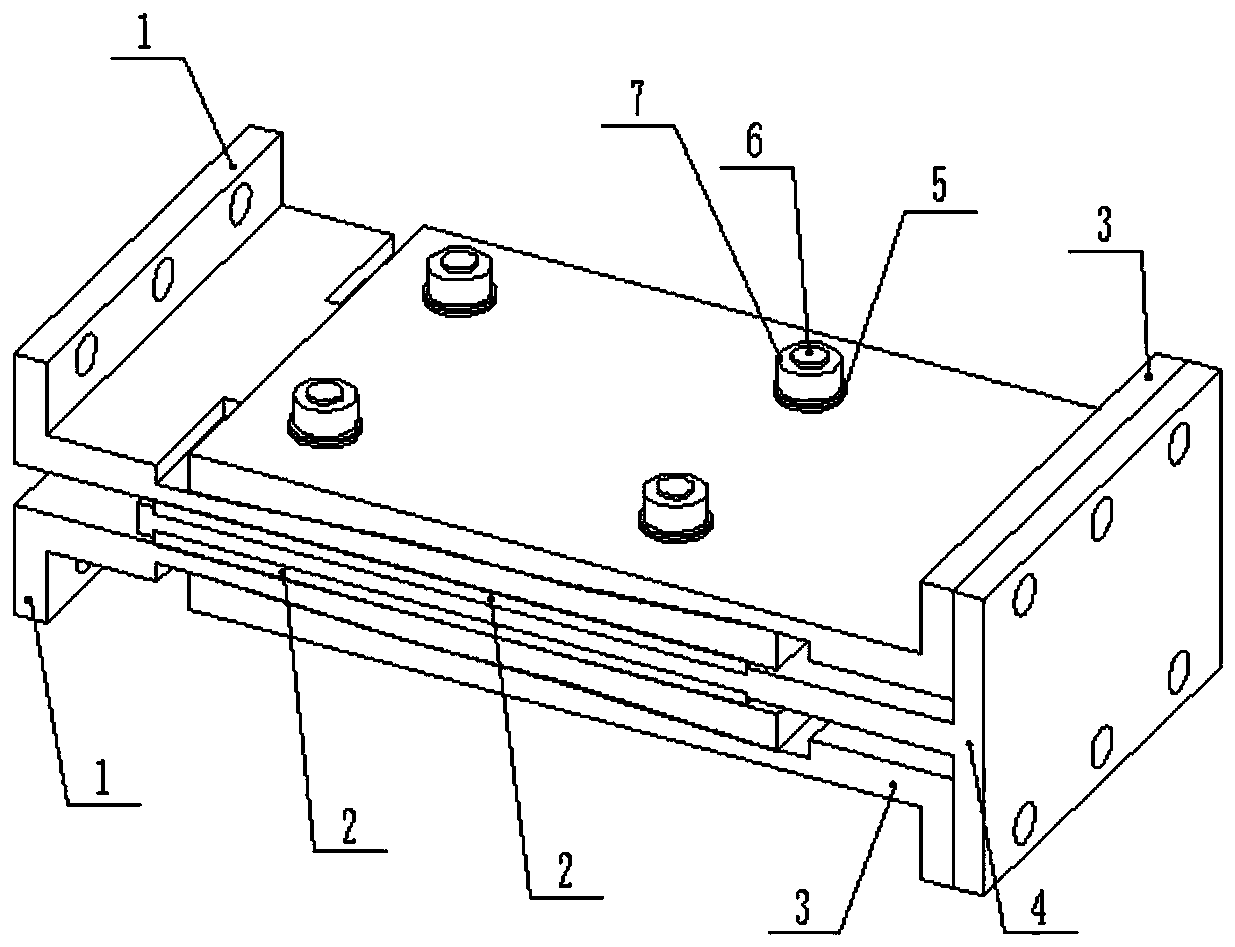

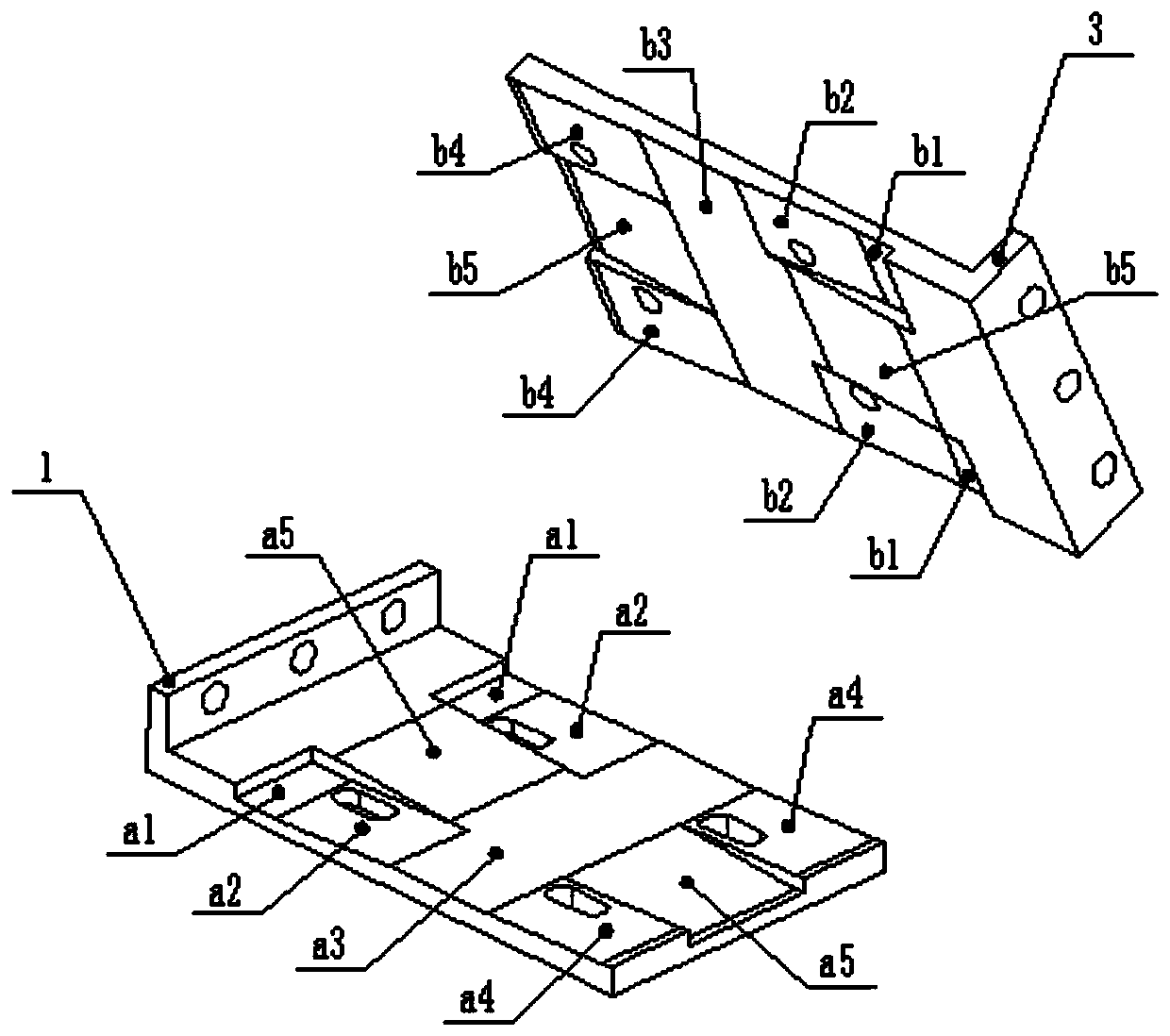

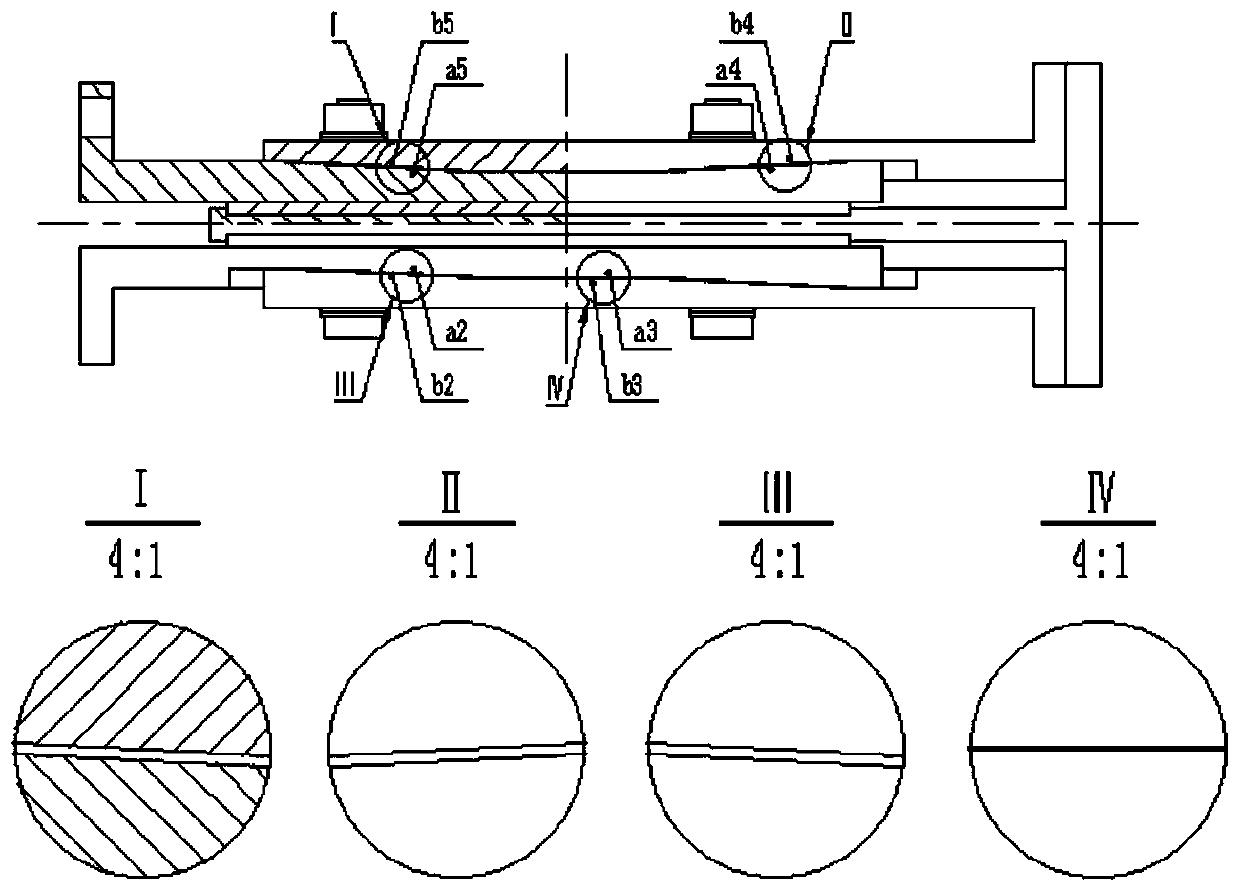

[0026] Such as figure 1 As shown, the damper includes sliding plate 1, friction plate 2, fixed plate 3, core plate 4, butterfly spring 5, pre-tightening bolt 6 and pre-tightening nut 7; fixed plate 3, sliding plate 1 and friction plate 2 are all Used in pairs, the pre-tightening bolts 6 and pre-tightening nuts 7 are symmetrically installed, and the pre-tightening nuts 7 and the fixing plate 3 are directly provided with butterfly springs 5; two friction plates 2 are embedded in the upper and lower sides of the core plate 4 to be fixed, and the core plate 4 is placed between two sliding plates 1, and the contact surface between sliding plate 1 and frictio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com