Rotation limitation and orientation identification mechanism and limiting and identifying method thereof

A direction recognition and rotation limit technology, which is applied in the direction of devices, mechanical control devices, and instruments that prevent/restrict/restore the movement of parts of the control mechanism, and can solve problems such as damage, complicated limit devices, and inconvenient use. To achieve the effect of simple use and clever design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

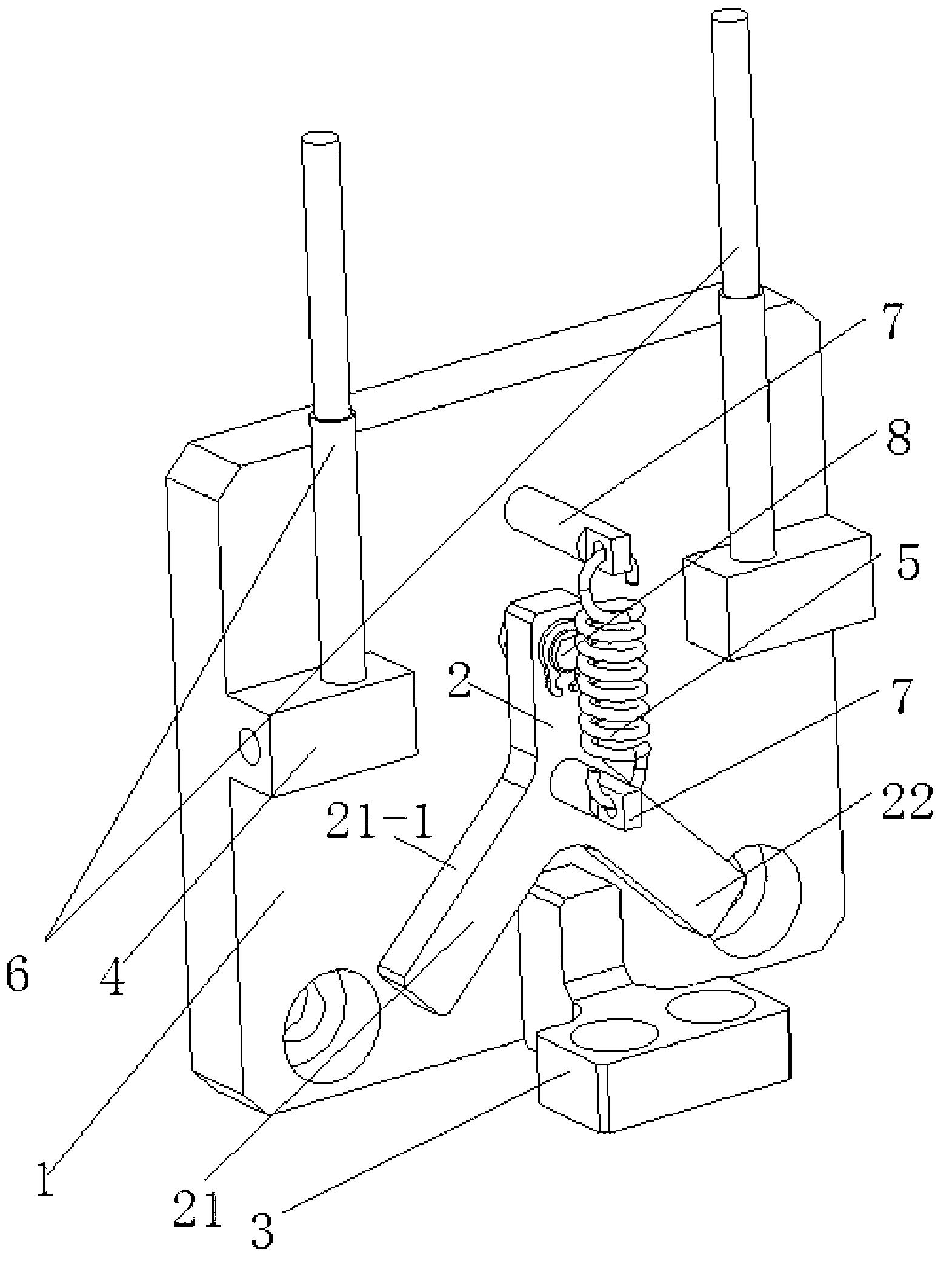

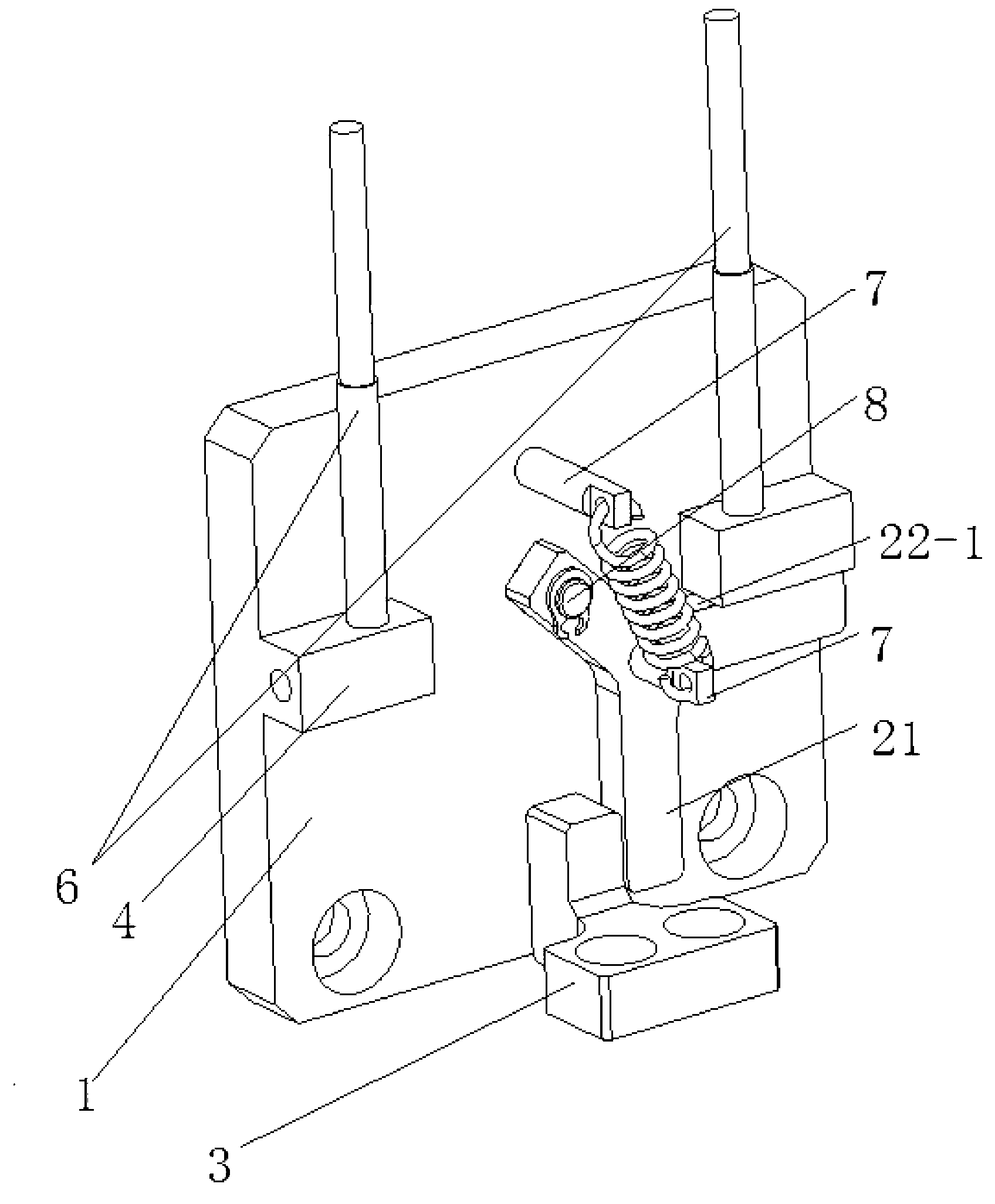

[0021] See figure 1 with figure 2 , a rotation limit and direction identification mechanism of this embodiment, including a base plate 1, a rotation plate 2, a striker 3, two stoppers 4, elastic members 5, two direction identification elements 6, and two elastic member hook columns 7 and reel 8. Elastic member 5 adopts extension spring, certainly also can be other objects that can provide upward pulling force for rotating wrench 2, such as rubber band and the like.

[0022] See figure 1 , the rotating plate 2 in this embodiment is in an inverted "Y" shape, the upper end is connected to the bottom plate 1 through the rotating shaft 8, and the lower end includes a left limiting plate 21 and a right limiting plate 22 that are connected at one end and form an included angle at the other end, The angle between the left limiting side 21 - 1 and the right limiting side 22 - 1 on the outside of the left limiting plate 21 and the right limiting plate 22 is 90°.

[0023] The strike...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com