A crusher device for hydraulic engineering

A technology of water conservancy projects and crushers, which is applied in the direction of grain processing, etc., can solve the problems of poor crushing effect, reduce the working efficiency of the crusher, and cannot control the size of the crushed and discharged particles, so as to achieve better crushing effect and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

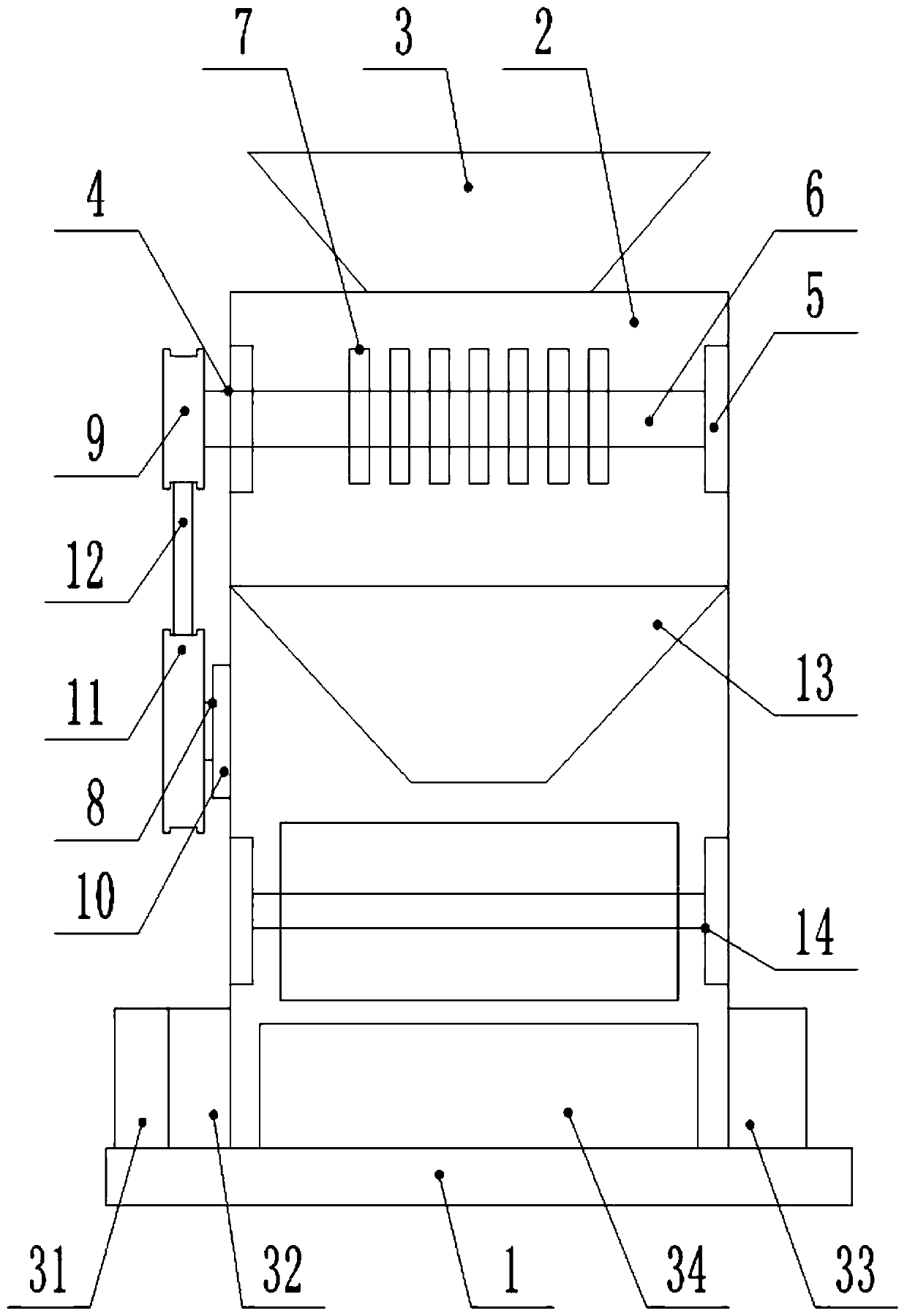

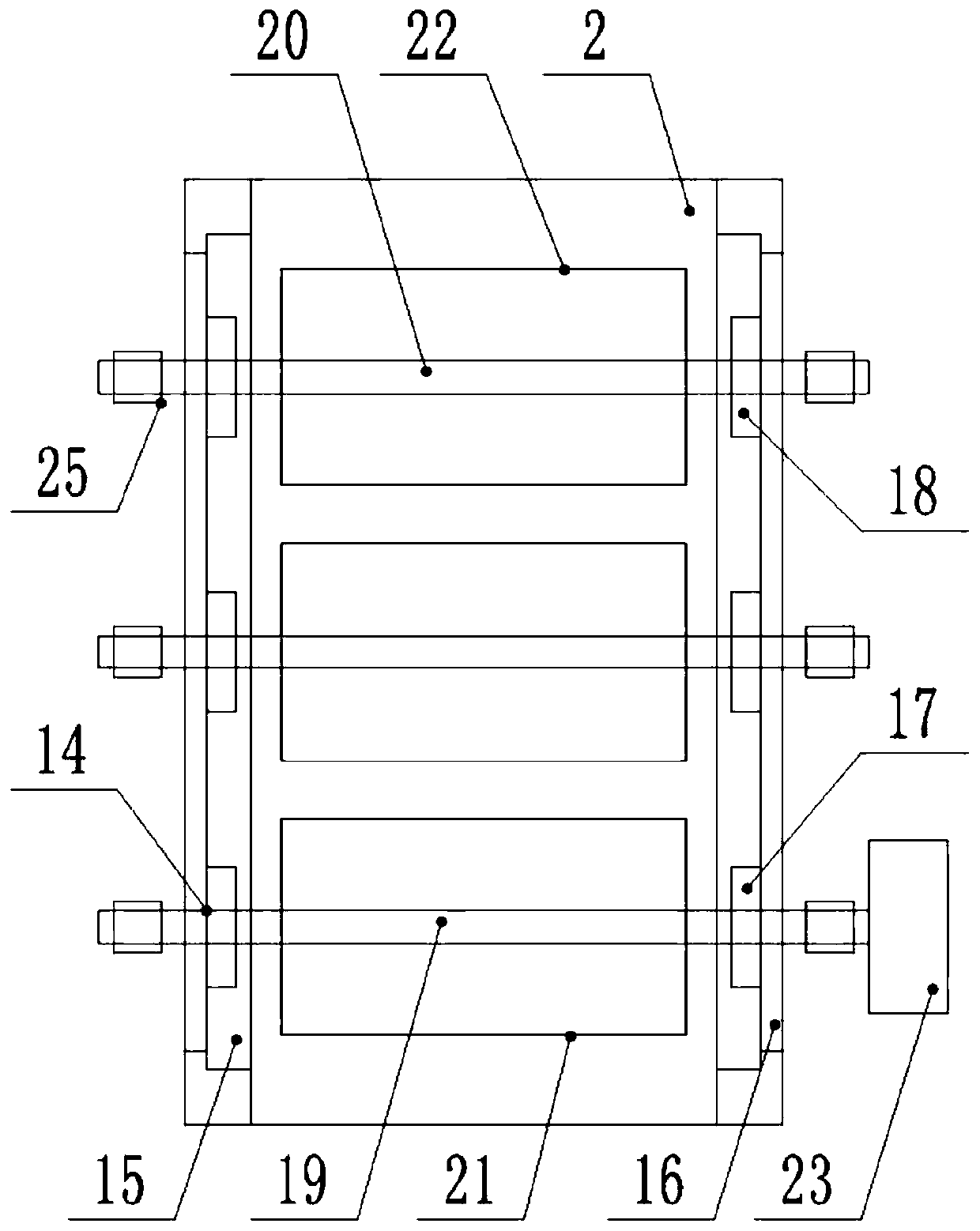

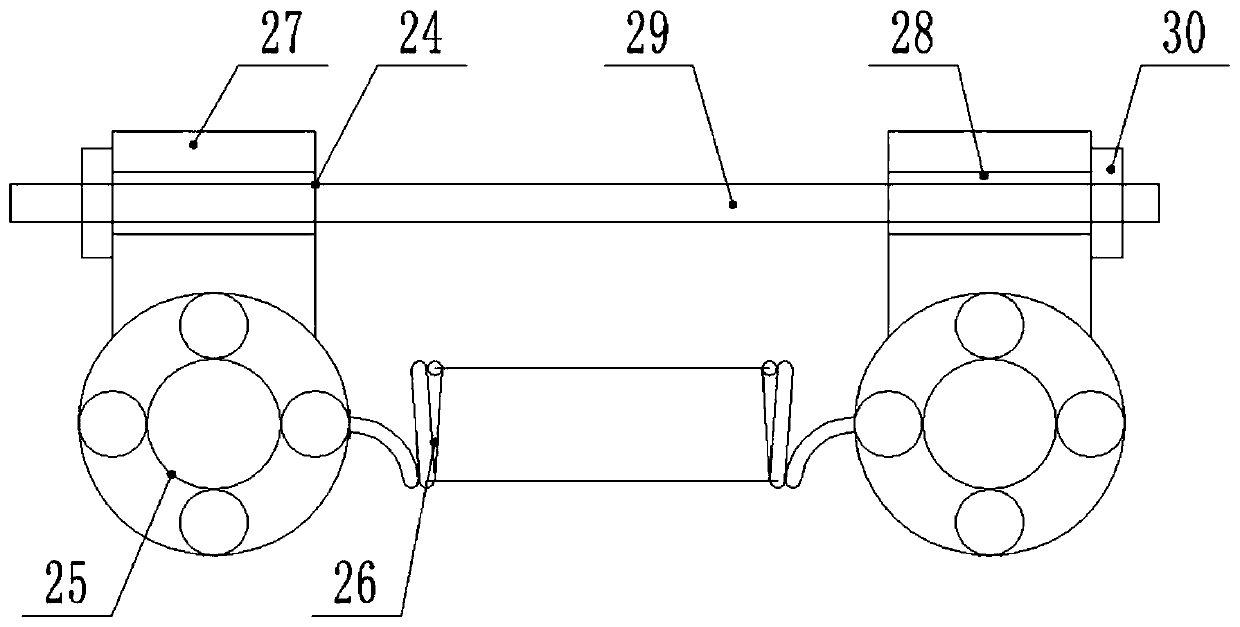

[0019] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-3 As shown, a crusher device for water conservancy projects includes a basic rectangular base 1 and a basic rectangular crushing box 2, the basic rectangular base 1 is placed on the ground, and the basic rectangular crushing box 2 is fixed on the The upper end of the basic rectangular base 1, the upper end of the basic rectangular crushing box 2 is provided with a feeding funnel 3 and the lower end of the feeding funnel 3 communicates with the inner cavity of the upper end of the basic rectangular crushing box 2, and the basic rectangular crushing box 2 The upper end of the inner cavity is provided with a primary crushing device 4, and the primary crushing device 4 is formed by the inner cavity at the upper end of the basic rectangular crushing box 2 corresponding to the discharge end of the feeding funnel 3 and along the basic rectangular crushing box. 2 A group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com