A kind of precision winding method of optical fiber ring

A winding method and technology of optical fiber rings, which are applied in the directions of instruments, surveying and navigation, and measuring devices, can solve the problems of large drift of optical fiber rings, affect the accuracy of inertial gyroscopes, and cannot guarantee the geometric symmetry of optical fiber rings. The effect of bit drift, ensuring geometric symmetry, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] A precision winding method for an optical fiber ring of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

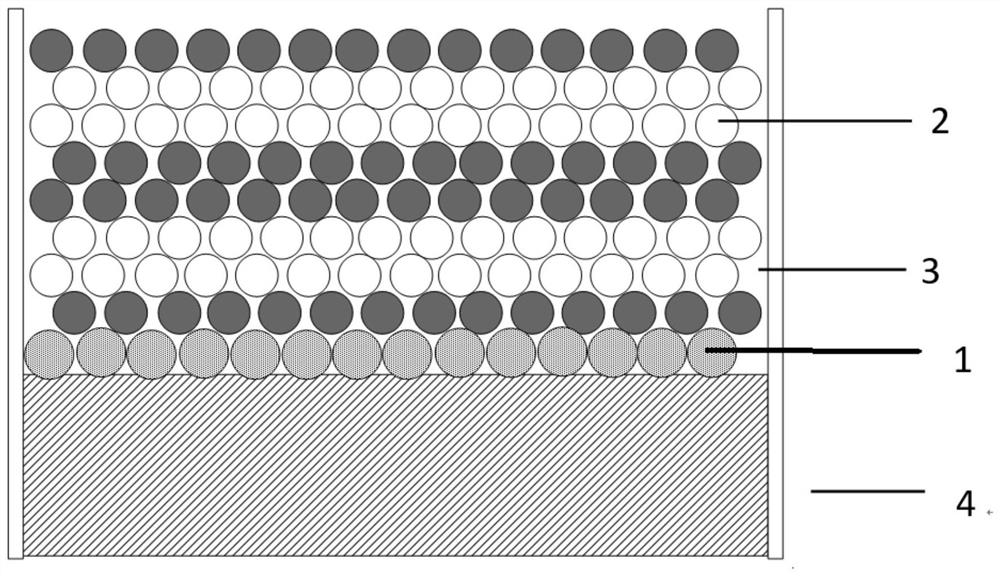

[0035] In this embodiment, the optical fiber ring wound on the winding tool 4 is as follows: figure 1 As shown, for a certain precision fiber optic gyroscope, a 1000m fiber optic fiber is used for fiber wrapping. The diameter of the fiber optic ring is designed to be 60-100mm. The height and thickness ratio of the ring is 3:1-1:1, so the height and thickness of the fiber ring can be determined. For the fiber ring using 165 μm fiber, the height is 10-15 mm, and the thickness is 4-6 mm. For the fiber ring using 135 μm fiber The fiber ring height is 8-12mm, and the thickness is 3-5mm.

[0036] According to the structural size of the optical fiber ring, the winding tooling 4 is processed, including the winding mandrel and the splints on both sides. The material is usually aluminum alloy, titanium al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com