Manufacturing method of aluminum alloy combined pipe for automobile gas spring

A kind of technology of automobile gas spring and manufacturing method, which is applied in the manufacture of aluminum alloy special-shaped tubes and the field of aluminum alloy round tubes, and can solve the problem of difficulty in meeting the high-quality requirements of aluminum alloys for automotive gas springs, poor plasticity and mechanical properties, and poor surface quality and other problems, to achieve the effect of moderate strength, high processing precision and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to further describe the present invention, the manufacturing method of the aluminum alloy special-shaped tube for the automobile gas spring of the present invention will be further described in detail below in conjunction with specific examples.

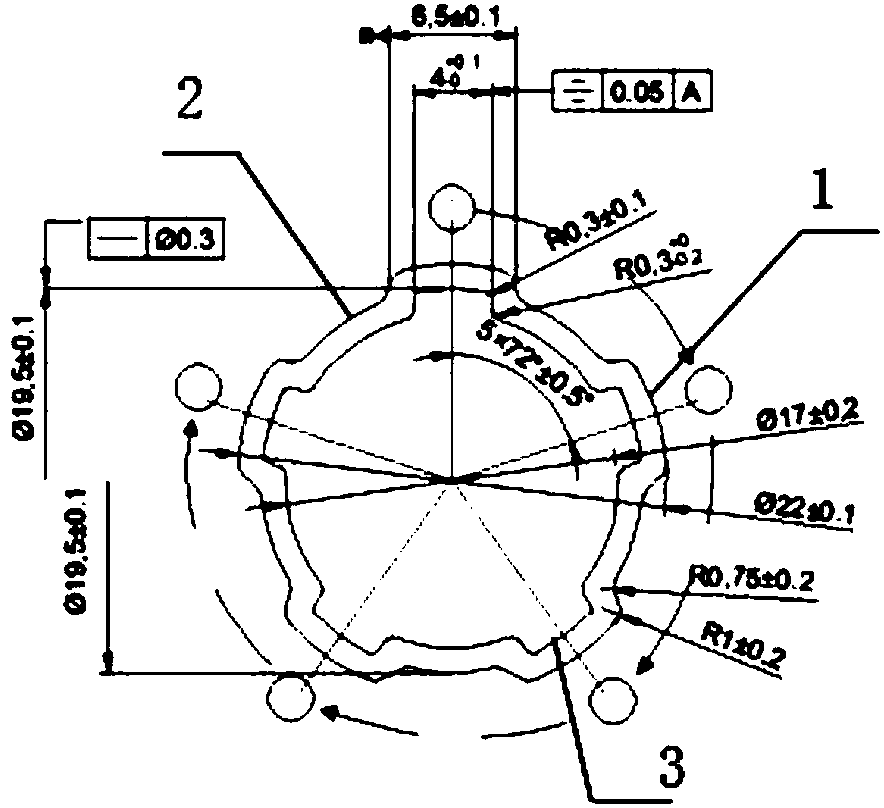

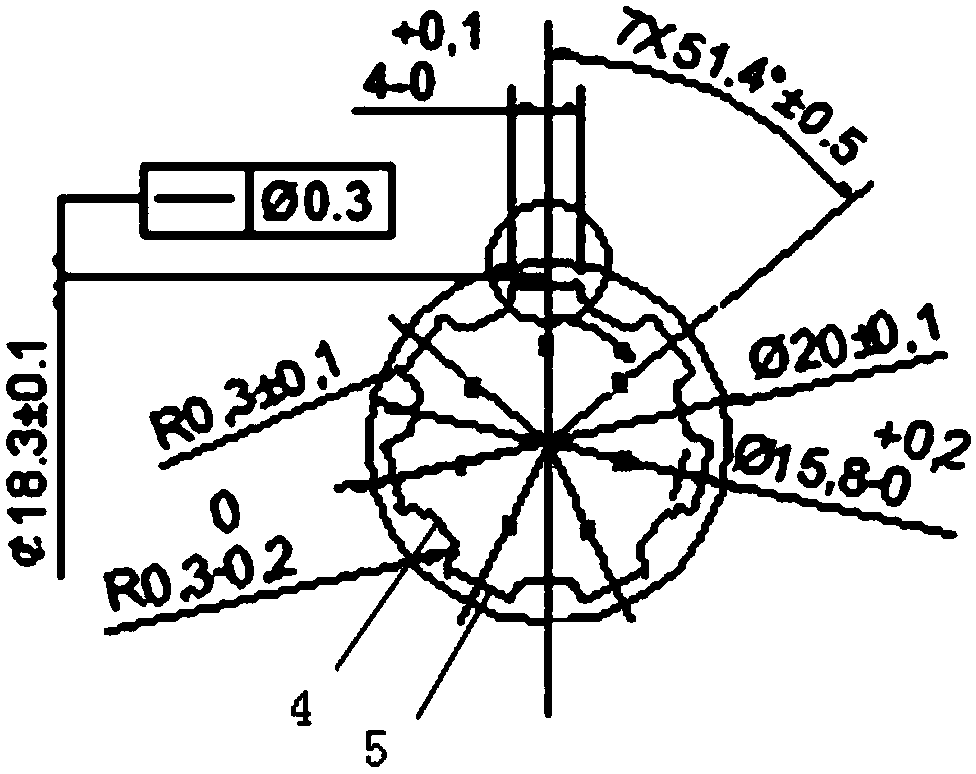

[0049] The aluminum alloy composite pipe fittings for automobile gas springs are composed of aluminum alloy special-shaped pipes for automobile gas springs and aluminum alloy round pipes for automobile gas springs, wherein one end of the aluminum alloy round pipes for automobile gas springs is set and welded on the Aluminum alloy special-shaped tube for automobile gas spring.

[0050] A: Manufacturing method of aluminum alloy round tube for automobile gas spring

[0051] In the present invention, the mass percent content of each alloy element in the raw material of the aluminum alloy round tube for the automobile gas spring is: Si 0.48% to 0.52%, Fe 0.16% to 0.20%, Cu≤0.05%, Mn≤0.05%, Mg 0.51% ~0.55%, Cr≤0.05%, Zn≤0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com