Manufacturing method of electronic parts module

An electronic component and manufacturing method technology, applied in the field of electronic component module manufacturing, can solve the problems of inability to prevent electric field noise and electromagnetic noise, achieve the effects of thinning and miniaturization, improving production efficiency, and reducing substrate area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

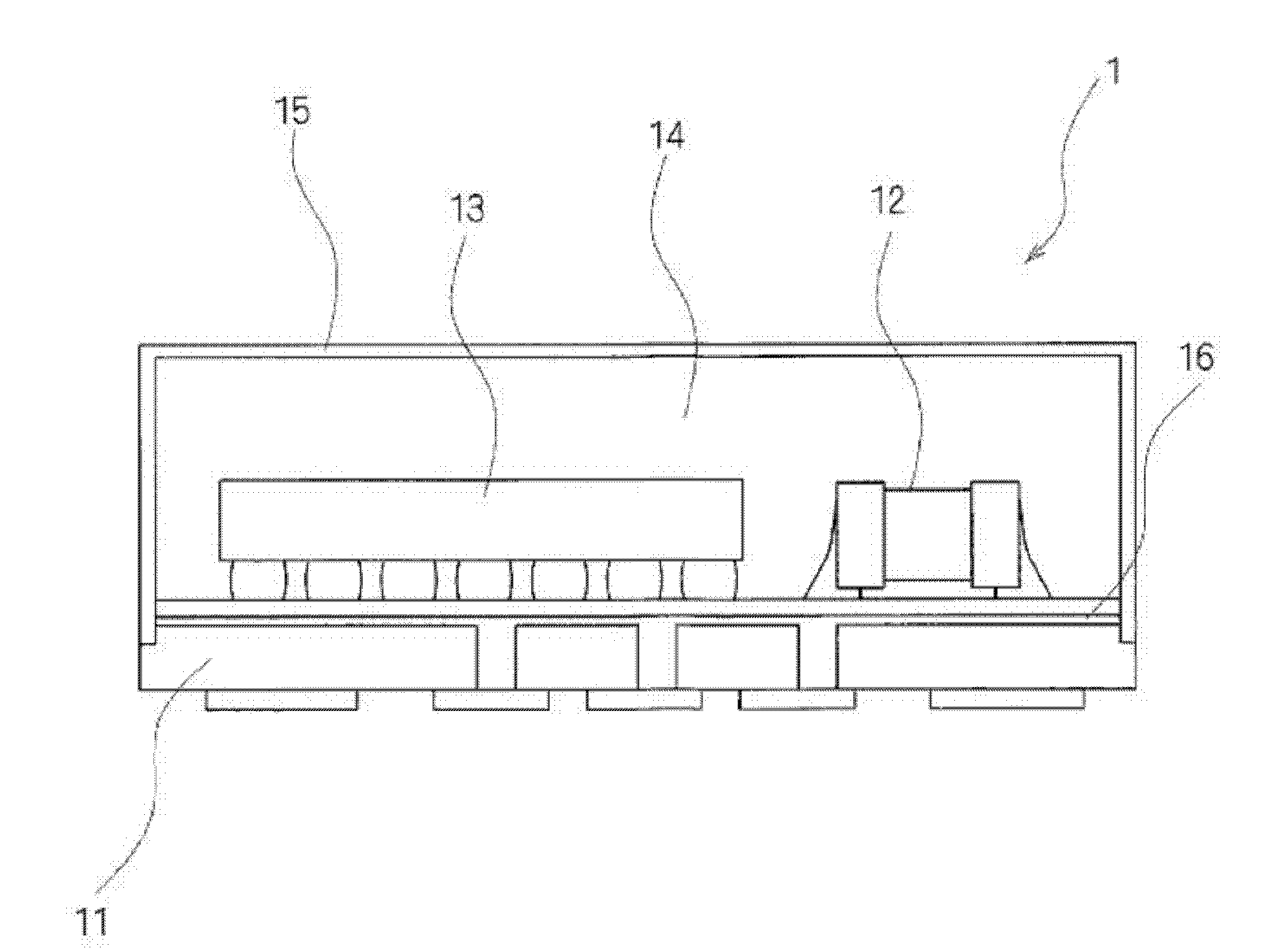

[0069] figure 1 It is a cross-sectional view showing the configuration of the electronic component module according to Embodiment 1 of the present invention. The electronic component module 1 according to Embodiment 1 of the present invention has, for example, a rectangular parallelepiped shape of 10.0 mm×10.0 mm×1.2 mm, and includes: a circuit board 11 made of ceramics, glass, epoxy resin, etc.; Electronic components 12, 12, ..., 13, 13, ... such as semiconductor elements on the surface, capacitors, resistors, and SAW filters.

[0070] The circuit board 11 is, for example, a resin substrate having a rectangular upper surface and a thickness of 0.5 mm. The surface of the circuit board 11 is provided with a signal pattern (not shown) serving as a bonding pad (electrode pad) between the electronic components 12, 12, ..., 13, 13, ... and a ground electrode on the side wall of the circuit board 11. 16. The signal pattern of the circuit board 11 is connected to terminals of ele...

Embodiment approach 2

[0087] Since the configuration of the electronic component module according to Embodiment 2 of the present invention and figure 1 The configuration of the electronic component module 1 according to Embodiment 1 shown is the same, and therefore the same reference numerals are used to omit detailed description.

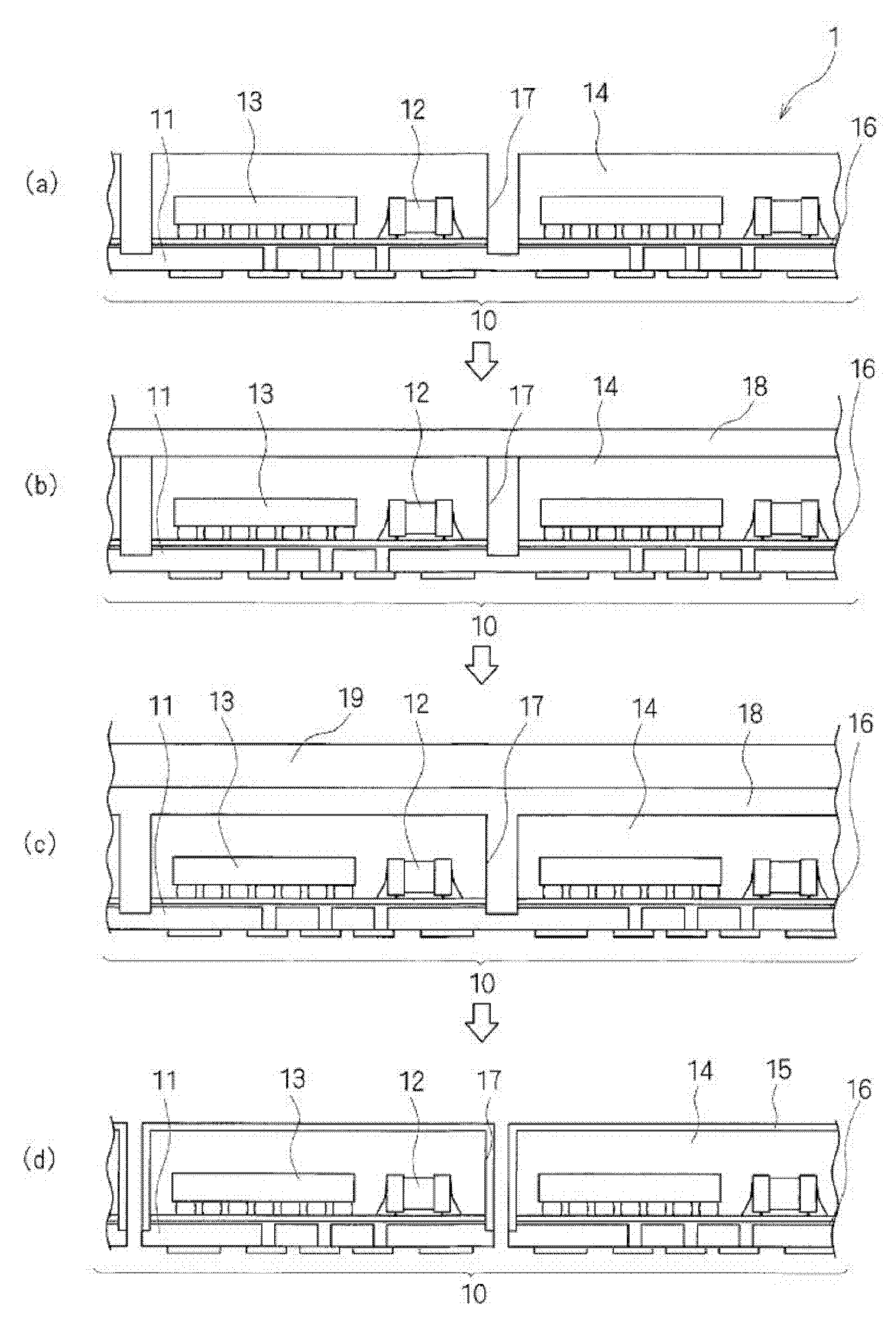

[0088] Figure 4 It is a sectional view explaining the manufacturing method of the electronic component module 1 which concerns on Embodiment 2 of this invention. Figure 4 (a) shows the state where the notch part 17 was formed after the sealing resin layer 14 was formed, Figure 4 (b) shows the state where the sheet-shaped conductive resin 18 is set, Figure 4 (c) shows the state where the collective substrate 10 is pressurized and heated by the pressure furnace device 21, Figure 4 (d) shows the state where the shielding layer 15 is formed. in addition, Figure 4 (a) and (b) of figure 2 (a) and (b) are the same.

[0089] As in Embodiment 1, the insulating lay...

Embodiment approach 3

[0097] Since the configuration of the electronic component module according to Embodiment 3 of the present invention and figure 1 The configuration of the electronic component module 1 according to Embodiment 1 shown is the same, and therefore the same reference numerals are used to omit detailed description.

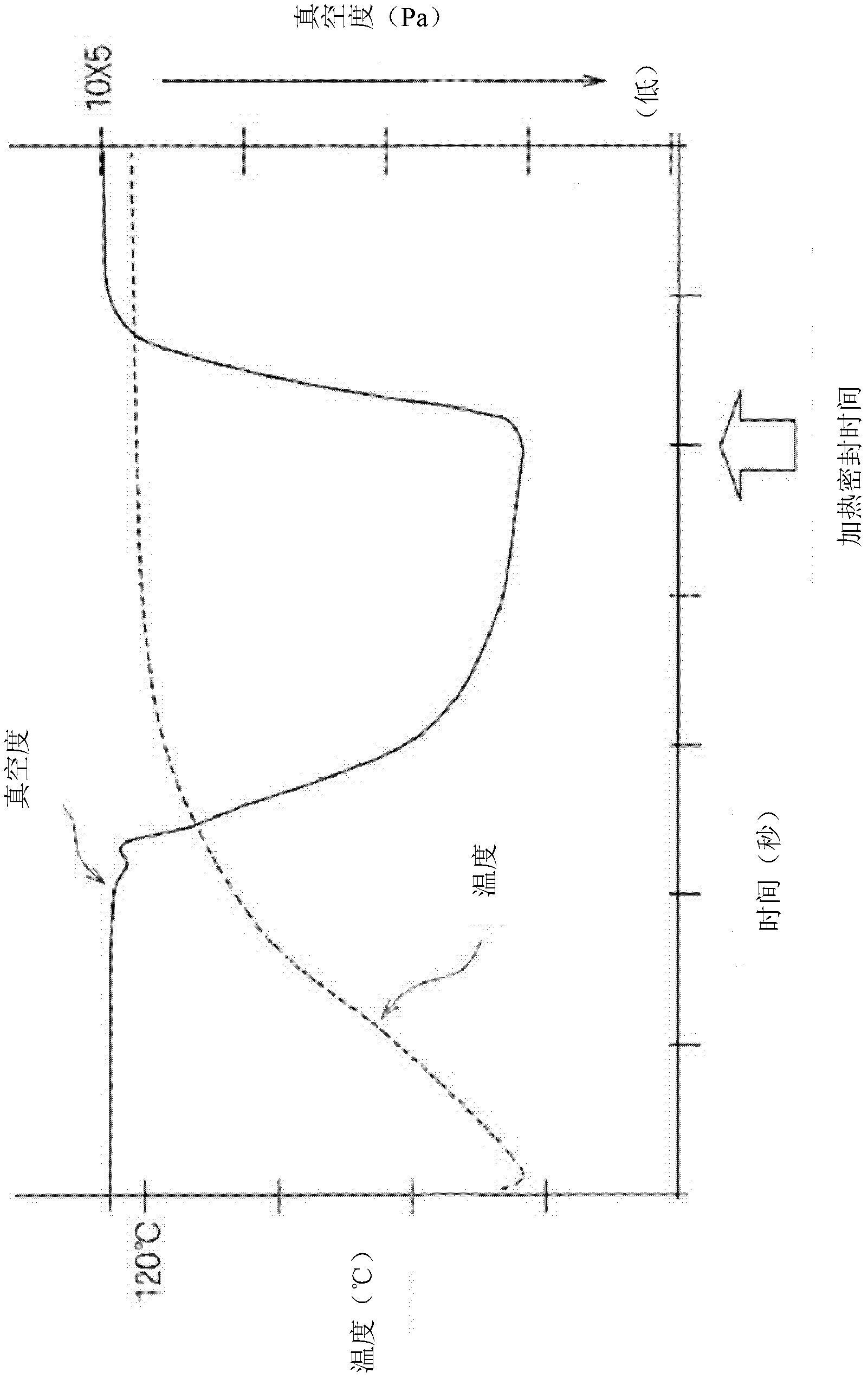

[0098] Figure 5 It is a sectional view explaining the manufacturing method of the electronic component module 1 which concerns on Embodiment 3 of this invention. Figure 5 (a) It is the state which formed the notch part 17 after forming the sealing resin layer 14, Figure 5 (b) shows the state where the sheet-shaped conductive resin 18 is set, Figure 5 (c) shows the state where the collective substrate 10 is placed in a gas-insulating bag 22 and decompressed, Figure 5 (d) shows the state where the aggregated substrate 10 in the depressurized bag 22 is heated. in addition, Figure 5 (a) and (b) of figure 2 (a) and (b) are the same.

[0099] As in Embodiment 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com