Protective safety net

A safety net and crossbar technology, applied in door/window protection devices, shutters/movable grilles, railings, etc., can solve the problems of high labor intensity, low efficiency, large space occupation, etc., and achieve fast and simple installation. Easy and fast operation, neat and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

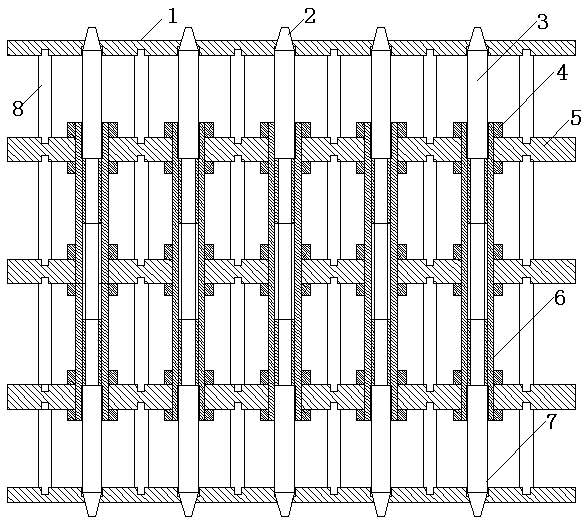

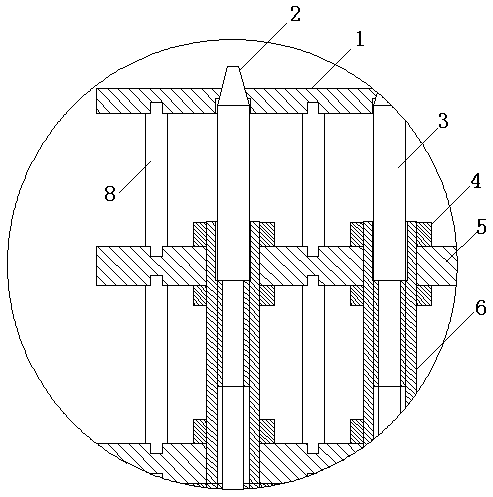

[0027] Such as figure 1 , figure 2 As shown, the protective safety net of the present invention includes a pole set, and the pole set is composed of at least two poles. The pole comprises a pole a3, a pole b7 and a connecting sleeve 6. The vertical rod a3 and the vertical rod b7 are respectively provided with threaded connection ends. The screw threads of the vertical rod a3 and the vertical rod b7 are screwed into the same direction of rotation. The two ends of the connecting rod or the connecting sleeve 6 are respectively provided with threads compatible with the threaded openings of the vertical rod a3 and the vertical rod b7. The vertical rod a3 and the vertical rod b7 are connected through the connecting sleeve 6 to form a vertical rod, and the screwing of the connecting sleeve 6 can make the two ends of the vertical rod or the cross bar retra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com