Manufacturing method of novel circular aluminium alloy tube for automobile gas spring

A technology for automobile gas springs and manufacturing methods, which is applied in the field of aluminum alloy round tubes, can solve the problems of difficulty in meeting the high-quality requirements of aluminum alloys for automobile gas springs, poor plasticity and mechanical properties, and poor surface quality, and achieve moderate strength, High processing precision and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further describe the present invention, the manufacturing method of the novel aluminum alloy round tube for the automobile gas spring of the present invention will be further described in detail below in conjunction with specific examples.

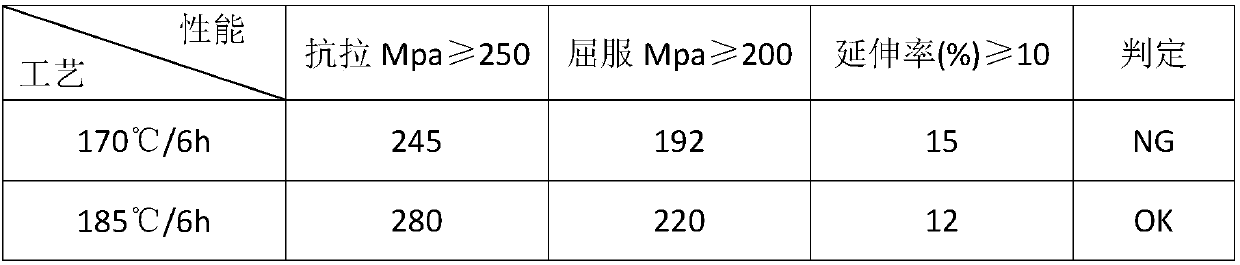

[0038] In the present invention, the mass percent content of each alloy element in the raw material of the new aluminum alloy round tube for automobile gas spring is: Si0.48%-0.52%, Fe 0.16%-0.20%, Cu≤0.05%, Mn≤0.05%, Mg0.51 %~0.55%, Cr≤0.05%, Zn≤0.05%, Ti 0.15%-0.25%, Pb 0.004%~0.01%, Ca+Na 0.001%-0.002%, other single element content≤0.05%, the total amount of other elements ≤0.15%, the rest is aluminum.

[0039] The aluminum rods of the above components are processed into new aluminum alloy round tubes for automobile gas springs by the following procedures and processes:

[0040] (1) Hot extrusion:

[0041]A 1000T horizontal extrusion machine is used, equipped with a 320KW power digital display adjustable electromagn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com