B-position omission perovskite anode material used for solid-oxide fuel battery

A solid oxide, fuel cell technology, used in fuel cell parts, battery electrodes, circuits, etc., can solve the problems of low ionic conductivity and electronic conductivity, and achieve improved ionic conductivity, stable performance, and good chemical compatibility. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

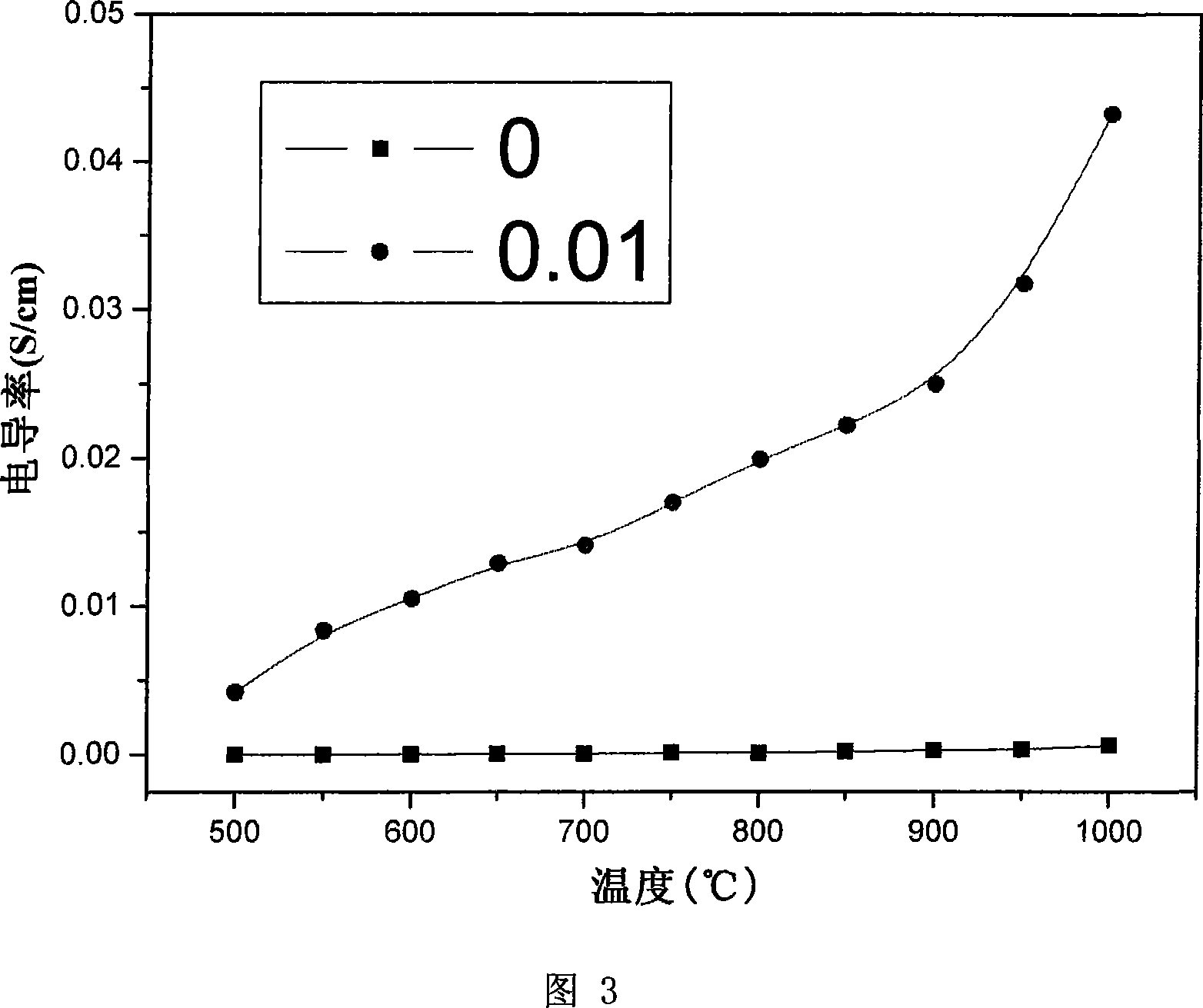

[0019] to Y 2 o 3 , SrCO 3 ,TiO 2 as raw material, according to Y 0.08 Sr 0.92 Ti 0.99 o 3-δ Prepare the mixture with the ratio of the elements, and use alcohol as the medium, mill it in an agate ball mill jar for 6 hours, mix it evenly, and dry it in an oven. Grind and sieve the dried powder (100 mesh), put the sieved powder in an alumina crucible, and store in 5% H 2 / Ar atmosphere, synthesized at 1300°C for 10 hours. Sieve the synthesized powder (100 mesh), add 40% by volume of carbon powder, 2% by volume of PVA solution, mix and dry press to form, and keep the prepared sample at 1500°C for 5 hours to make a porous anode material . The total conductivity of the material at 1000°C is 33.34S / cm, and the ion conductivity is 4.32×10 -2 S / cm, as shown in Figure 3, when the vacancy is 0.01, the ionic conductivity of the material at each temperature is much higher than that of the non-defective sample. Under the condition of 1000℃ and YSZ, La 0.8 Sr 0.2 Ga 0.8 Mg 0....

Embodiment 2

[0021] With Y(NO 3 ) 3 , Sr(NO 3 ) 2 , TiCl 4 as raw material, according to Y 0.08 Sr 0.92 Ti 0.97 o 3-δ The mixture was prepared in the ratio of the elements, and the reaction was carried out in a sealed autoclave with 1 mol / L potassium hydroxide solution as the solvent, and the temperature of the autoclave was raised to 150 ° C for 30 min. After the autoclave was cooled naturally, the precipitate was washed and dried to obtain a synthesized powder. Sieve the synthesized powder (160 mesh), take 1g powder, add 10% mass fraction of soluble starch and 1% mass fraction of ethyl cellulose, finally add 1ml deionized water, mix well and use screen printing The method is evenly coated on the surface of the dense electrolyte YSZ fired at high temperature, and kept at 1550 ° C for 10 hours to make a porous anode film material. The total conductivity of the material at 1000°C is 28.52S / cm, and the ion conductivity is 2.13×10 -2 S / cm, under the condition of 1000 ℃ and YSZ, La ...

Embodiment 3

[0023] Press (Y 0.08 Sr 0.92 ) 0.95 TiO 3-δ The stoichiometric ratio weighs tetrabutyl titanate (chemically pure), Y 2 (CO 3 ) 3 (analytical pure) and SrCO 3 (analytical pure). First mix tetrabutyl titanate with ethylenediaminetetraacetic acid (EDTA, analytically pure), where the molar ratio of EDTA to titanium ions is 1:1, add water to dissolve, stir in a water bath at 80°C until clear, and then add Y 2 (CO 3 ) 3 and SrCO 3 ; Add citric acid according to the molar ratio of citric acid (analytically pure) to titanium ion at a ratio of 4:1, adjust the pH value to 8-9 with ammonia water, and obtain a light yellow transparent sol by heating and stirring. The sol is dried in an oven to obtain a transparent gel, and the gel is heated and coked to obtain a porous sponge-like coked product. The primary powder, namely the precursor, is obtained after the coking product is ground. The primary powder is heat treated in the temperature range of 500-600°C to obtain the synthet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com