Platform of principal axis with paralleled Z, A two degrees of freedom driven by linear motor

A linear motor, degree of freedom technology, used in metal processing machinery parts, large fixed members, metal processing equipment and other directions, can solve the problems of singular motion interference, small working space, etc., to achieve high motion speed, fast feed speed, deflection wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

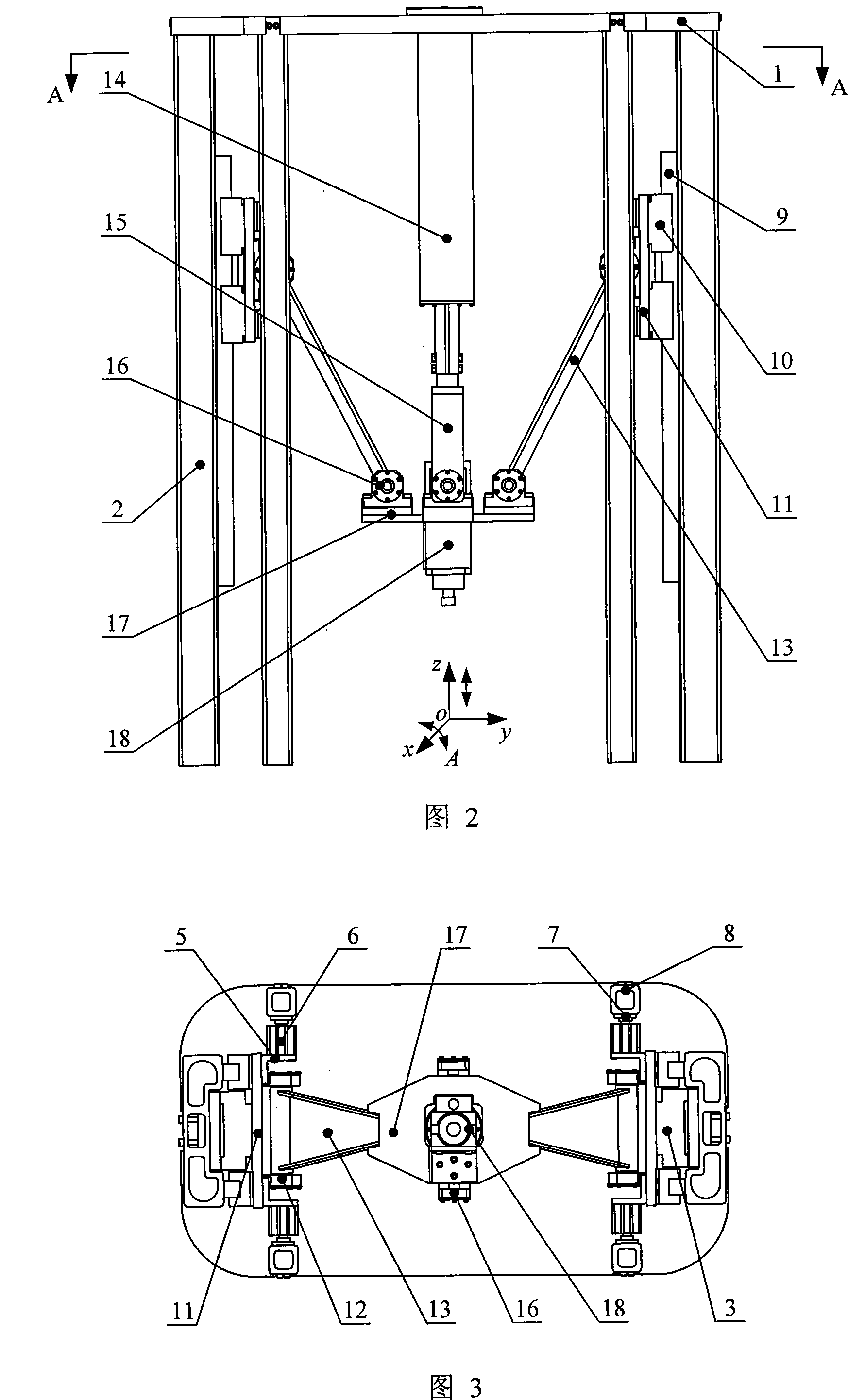

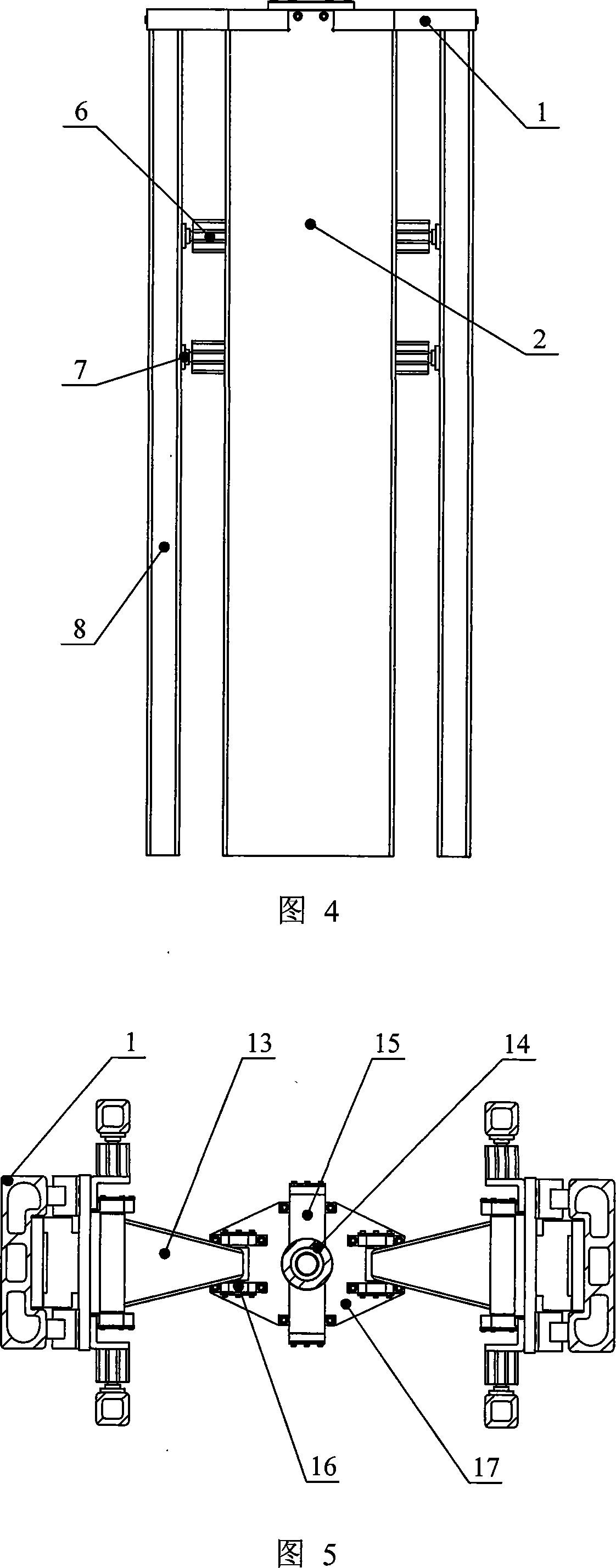

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings.

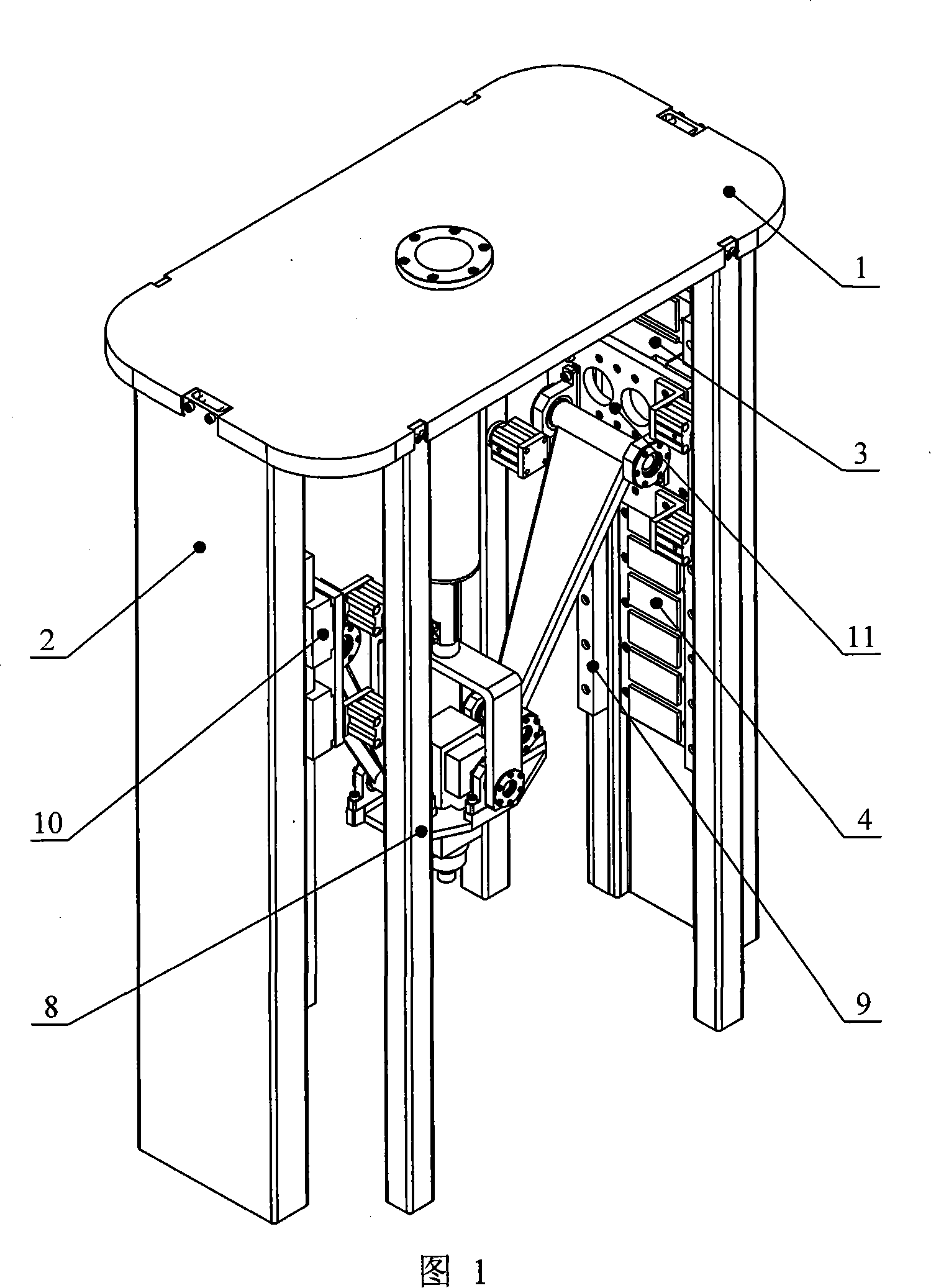

[0030] A Z-A two-degree-of-freedom parallel spindle platform driven by a linear motor of the present invention includes: a static platform 1, a column 2, a linear motor mover 3, a linear motor stator 4, a self-locking device, two moving subassemblies, and two rotating Subassembly A 12, two connecting rod assemblies 13, telescopic rod 14, U-shaped shift fork 15, three rotating subassembly B 16, moving platform assembly 17 and main shaft assembly 18;

[0031] As shown in Figure 1, two U-shaped groove-shaped columns 2 are distributed in parallel and opposed to each other, and are respectively fixed to the static platform 1 through screw connections. The linear motor stator 4 is respectively fixed in the U-shaped grooves in the column 2 with screws. The friction column 8 is also connected with the static platform 1 by screws, and fixed at the position shown in FI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com