Cold rolling hot-dip galvanizing high-strength steel with extension strength being 1,000 MPa and preparation method of cold rolling hot-dip galvanizing high-strength steel

A technology of hot-dip galvanizing and tensile strength, applied in hot-dip galvanizing process, coating, metal material coating process, etc., to achieve good adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of the hot-dip galvanized high-strength steel with a tensile strength of 1000MPa comprises the following steps:

[0045] (1) Smelting process;

[0046] (2) Hot continuous rolling and coiling of cast slab or ingot: the cast slab is heated at 1200-1250°C, rolled by rough rolling mill for 5-7 passes, and rolled to a thickness of 30-60mm; The unit conducts 5-7 passes of rolling to a thickness specification of 2.2-4.5mm, the starting rolling temperature is 1000-1150°C, the final rolling temperature is 860-920°C, and the coiling temperature is 450-600°C;

[0047] (3) Hot-rolled coil cover removal: the hot-rolled coil cover removal temperature is 600-800°C, and the cover-removal time is 24-72h;

[0048] (4) Pickling and cold rolling: pickling the steel strip in a hydrochloric acid tank to remove the surface oxide scale, then performing cold continuous rolling or cold rolling, the acid rolling reduction rate is 45-60%, and rolling to the target thickness...

Embodiment 8

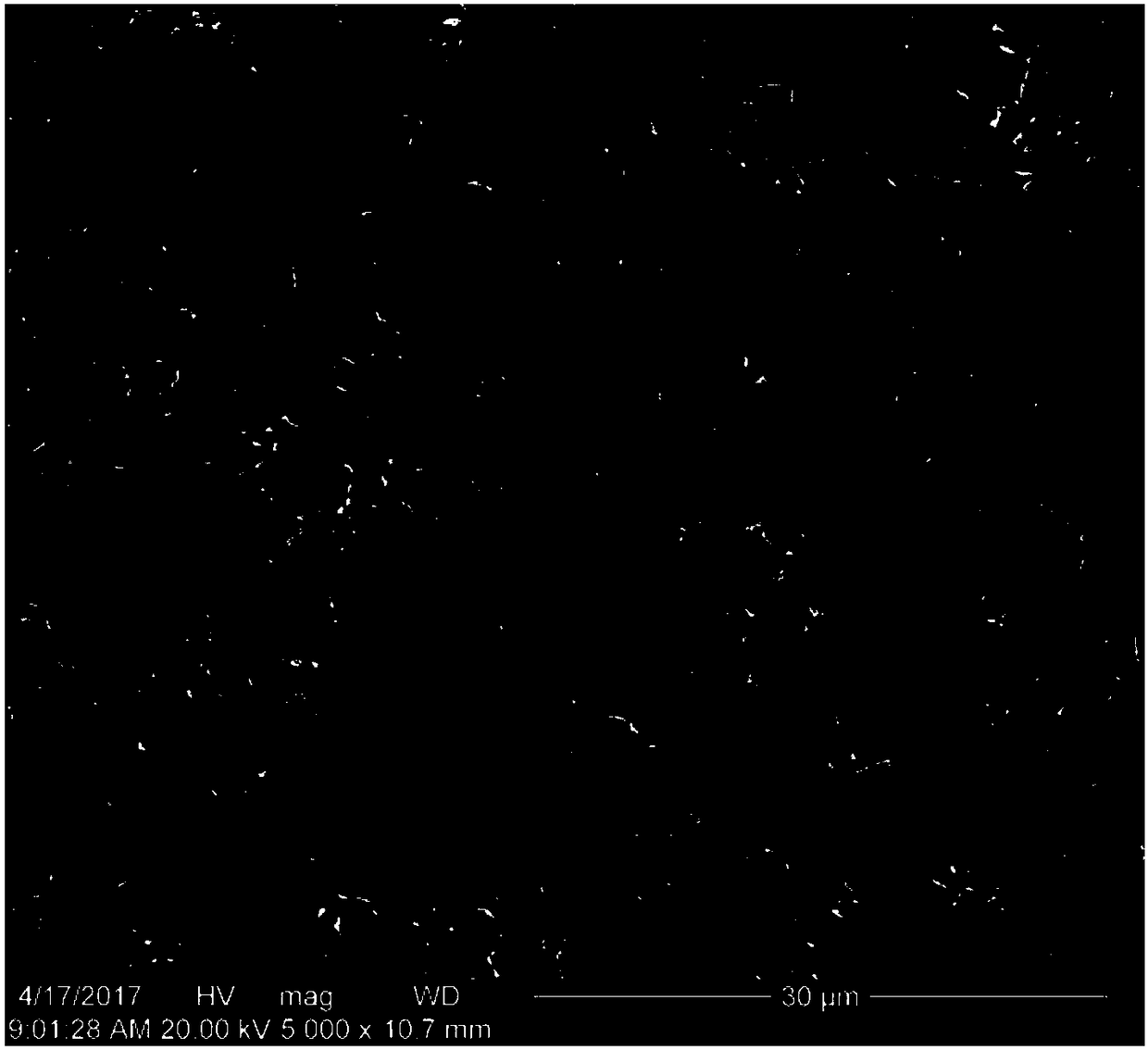

[0059] The metallographic structure photo of the hot-dip galvanized high-strength steel obtained in embodiment 8 is as follows figure 1 As shown, the scanning electron microscope photo is shown as figure 2 As shown, the zinc layer on the surface of the steel plate was corroded by 5% HCl solvent + corrosion inhibitor, and the morphology of the inhibition layer of the pure zinc coating was taken by scanning electron microscope, as shown in image 3 shown. from figure 1 and figure 2 It can be seen that the finished product structure is mainly ferrite and martensite, of which ferrite accounts for about 50%, martensite and / or bainite accounts for about 50%, and the hard phase martensite\and / or bainite uniformly distributed in ferrite; from image 3 It can be seen that when the pure zinc layer is eroded, the substrate surface is evenly distributed with "rice grain" inhibition layer particles (Fe-Al alloy phase), indicating that the inhibition layer on the substrate surface is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com