Online control method and system capable of maintaining steel-making and continuous casting production stability

A control method and stability technology, which is applied in the field of online control methods and systems to maintain the stability of steelmaking-continuous casting production, can solve the problem that the initial scheduling plan cannot maintain good continuity and stability, the initial scheduling plan has a large impact, Unfavorable production stability and smooth operation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

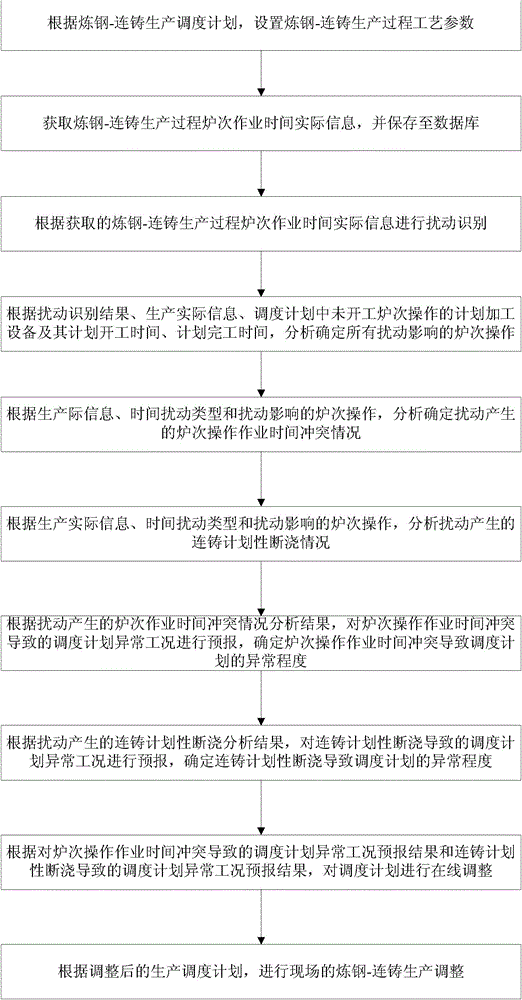

[0063] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

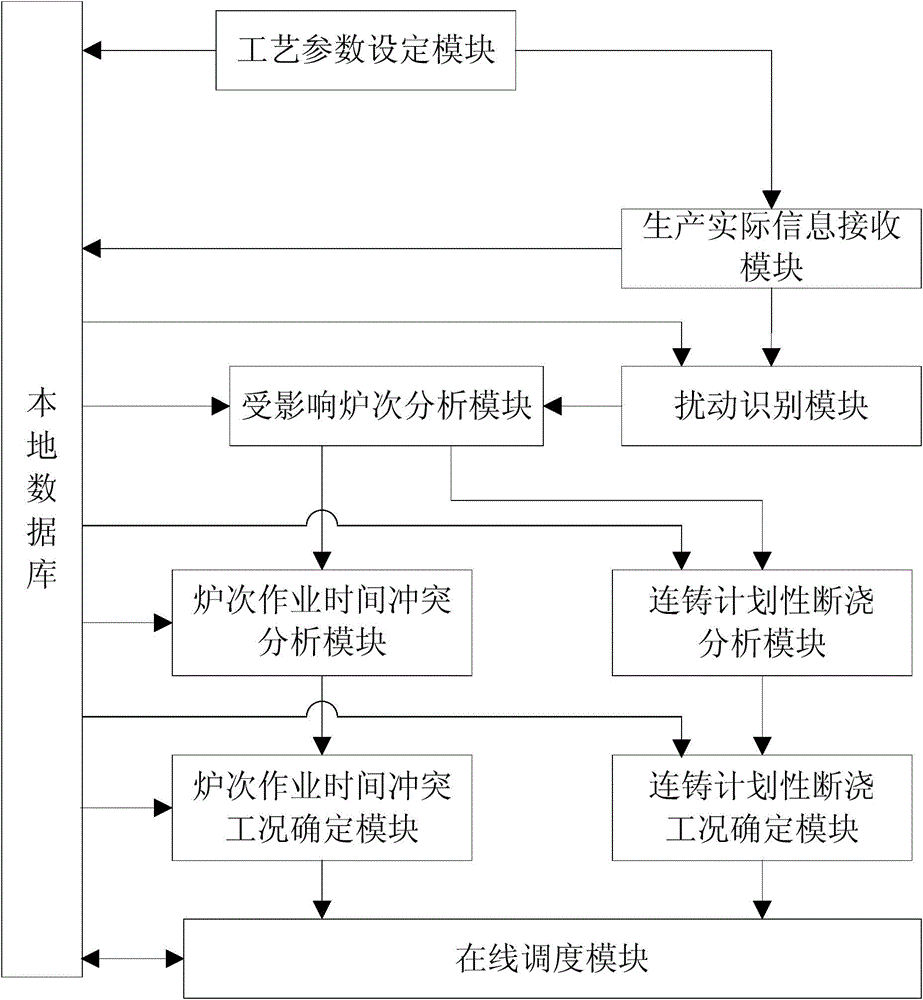

[0064] The online control method for maintaining the stability of steelmaking-continuous casting production in this embodiment is realized by an online control system for maintaining the stability of steelmaking-continuous casting production, such as figure 1 As shown, the system includes process parameter setting module, actual production information receiving module, disturbance identification module, affected heat analysis module, heat operation time conflict analysis module, continuous casting planned pouring interruption analysis module, heat operation time Conflict working condition determination module, continuous casting planned pouring interruption determination module, online scheduling module and local database.

[0065] The process parameter setting module is used to set the process parameters of the steelmaking-continuous c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com