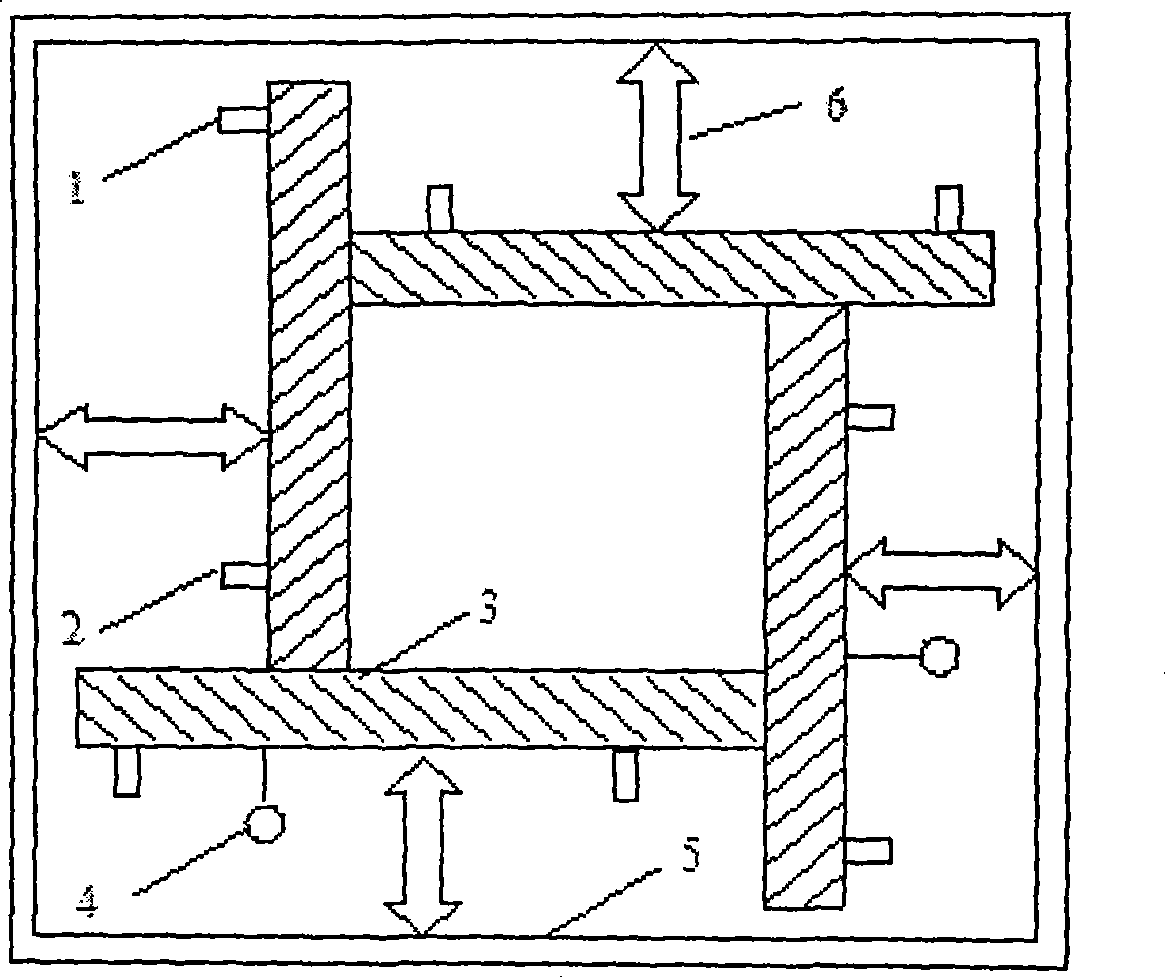

Casting mold experimental equipment for technology under simulating light press continuous casting blank and method

A kind of experimental equipment, light pressing technology, applied in material inspection products, testing metals, optical testing flaws/defects, etc., can solve the problems of grain nucleation, growth and lack of experimental methods for phase transformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] When carrying out the experiment, according to the specific experimental design, a certain flow of cooling water is introduced, and the smelted molten steel is injected into the soft-pressed casting mold. ), set the process parameters (light reduction position, reduction amount, reduction rate, reduction force, etc.) Shrinkage, after the slab is solidified and cooled, slice and sample the slab after solidification, observe the microstructure evolution of the slab during solidification and crystallization, focusing on central segregation, internal looseness and cracks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com