Experimental device and experimental method for simulating low-speed solidification of extra-thick plates

An experimental device and technology for extra-thick plates, applied in the field of steelmaking and continuous casting, can solve problems such as lack of experimental means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

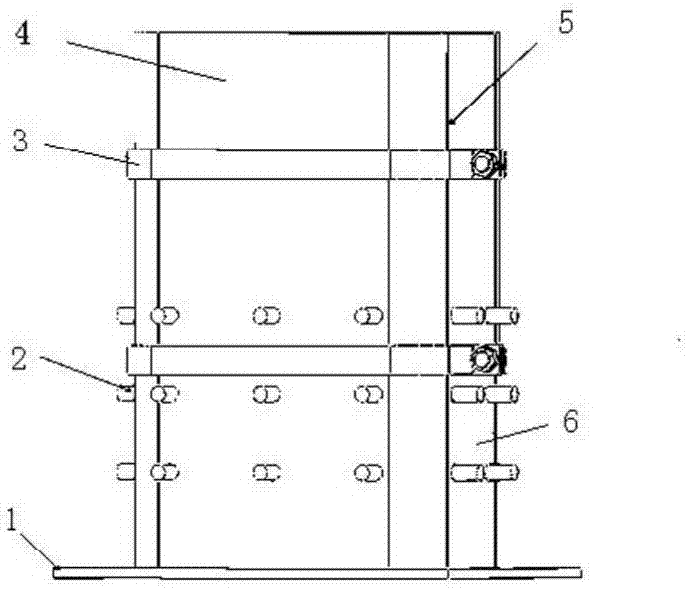

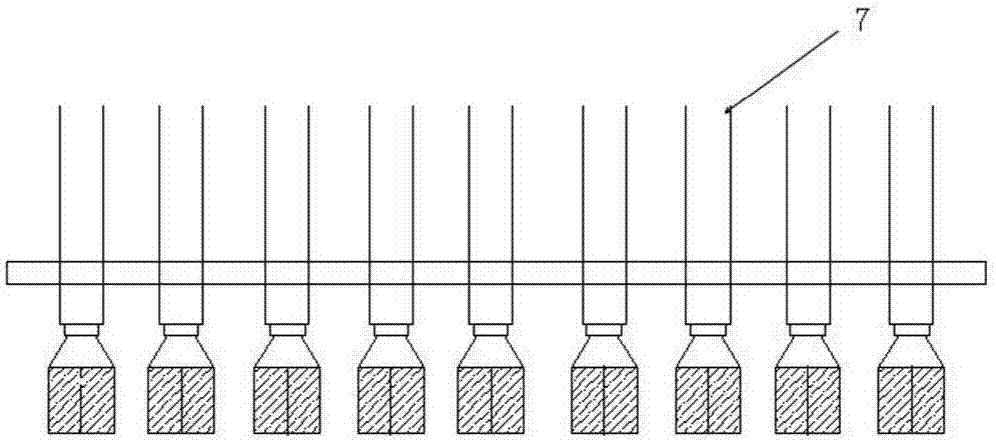

[0051] Embodiment 1: Carry out the experiment of slow solidification in magnesia crystallizer

[0052] Step 1: Determination of crystallizer material

[0053] According to the temperature requirements of the mold material, select materials with a maximum allowable temperature greater than or equal to 1400°C; magnesia, clay, silicon and chromium refractory materials all meet the requirements; select magnesia refractory materials, and the maximum allowable temperature of the material is 1600°C- 1700℃, thermal conductivity λ is 2.1W / (m.℃), density ρ is 2450kg / m 3 , the specific heat capacity Cp is 1250J / (kg.℃), and α=6.857×10 from α=λ / (ρ·Cp) -7 ; α∈(2.676×10-7, 21.41×10-7), so magnesia refractories can be used as materials for slow solidification crystallizers;

[0054] Step 2: Determination of crystallizer size

[0055] According to the size of the crystallizer that can produce 420mm×2020mm extra-thick slab, according to the requirement that the geometric similarity ratio is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com