Cold-rolled steel strip for high-drawing-performance flux-cored wire, and making method thereof

A technology of cold-rolled steel strip and flux-cored welding wire, which is applied to the field of cold-rolled steel strip for flux-cored welding wire and its production, can solve the problems of unreachable composition, low elongation, high yield strength and tensile strength of steel strip, Achieve the effect of obvious aging problem, stable winding performance and improving drawing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

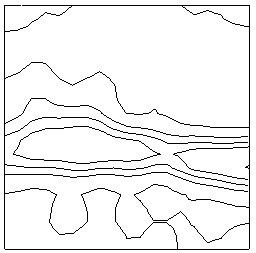

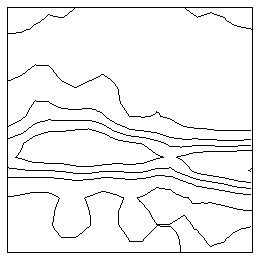

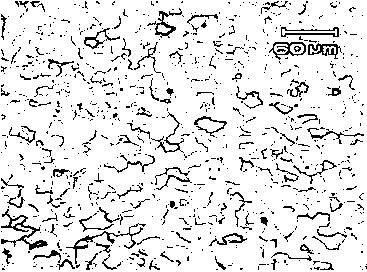

Image

Examples

Embodiment 1

[0057] The cold-rolled steel strip for high-drawability flux-cored wire includes the following components by weight: C 0.003%, Si 0.01%, Mn 0.15%, P 0.006%, S 0.003%, N 0.0025%, Alt (acid soluble aluminum) 0.032%, the balance is Fe and other unavoidable impurities.

[0058] The manufacturing method of the cold-rolled steel strip for the high-drawability flux-cored welding wire comprises the following steps:

[0059] (1) Steelmaking: a. Deep de-slagging of molten iron: Firstly, according to the requirements of the first-level slag removal, that is, the liquid surface is exposed to more than 3 / 4, remove the former slag of the molten iron, and then perform KR pretreatment on the molten iron at 1300-1380°C , when the rotating speed is 60r / min, add the desulfurizing agent according to the standard of 7 kg of desulfurizing agent / 1 ton of molten iron, and stir at a rotating speed of 85-95r / min. The content is 0.003%;

[0060] b. De-P and pre-de-C by double slag method of...

Embodiment 2

[0073] The cold-rolled steel strip for high-drawability flux-cored welding wire includes the following components in weight percentage: C0.0025%, Si 0.01%,

[0074] Mn 0.20%, P 0.005%, S0.002%, N 0.0030%, Alt 0.03%, the balance is Fe and other unavoidable impurities.

[0075] The manufacturing method of the cold-rolled steel strip for the high-drawability flux-cored welding wire comprises the following steps:

[0076] (1) Steelmaking: a. Deep desulfurization of molten iron: firstly remove the former slag of molten iron according to the requirements of the first-level slag removal, that is, the liquid surface is exposed to more than 3 / 4, and then perform KR pretreatment on the molten iron at 1300-1380°C. When the rotating speed is 60r / min, add desulfurizing agent according to the standard of 7kg desulfurizing agent / 1 ton of iron, and stir at a rotating speed of 85-95r / min. After stirring for 12 minutes, remove the slag so that the S content in the 0.002%;

[0077] ...

Embodiment 3

[0090] The cold-rolled steel strip for high-drawability flux-cored welding wire includes the following components in weight percentage: C0.0035%, Si 0.009%,

[0091] Mn 0.15%, P 0.007%, S 0.0008%, N 0.0040%, Alt 0.025%, the balance is Fe and other unavoidable impurities.

[0092] The manufacturing method of the cold-rolled steel strip for the high-drawability flux-cored welding wire comprises the following steps:

[0093] (1) Steelmaking: a. Deep desulfurization of molten iron: firstly remove the former slag of molten iron according to the requirements of the first-level slag removal, that is, the liquid surface is exposed to more than 3 / 4, and then perform KR pretreatment on the molten iron at 1300-1380°C. When the rotating speed is 60r / min, add desulfurizing agent according to the standard of 7kg desulfurizing agent / 1 ton of iron, and stir at a rotating speed of 85-95r / min. After stirring for 12 minutes, remove the slag so that the S content in the 0.0008%;

[0094] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com