Scheduling system and method for steel making and continuous casting production

A production scheduling and scheduling system technology, applied in the field of steelmaking-continuous casting, can solve the problems that the algorithm cannot be practically applied, the online test time is too long, and the steelmaking-continuous casting production scheduling algorithm is difficult to effectively guide the actual production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

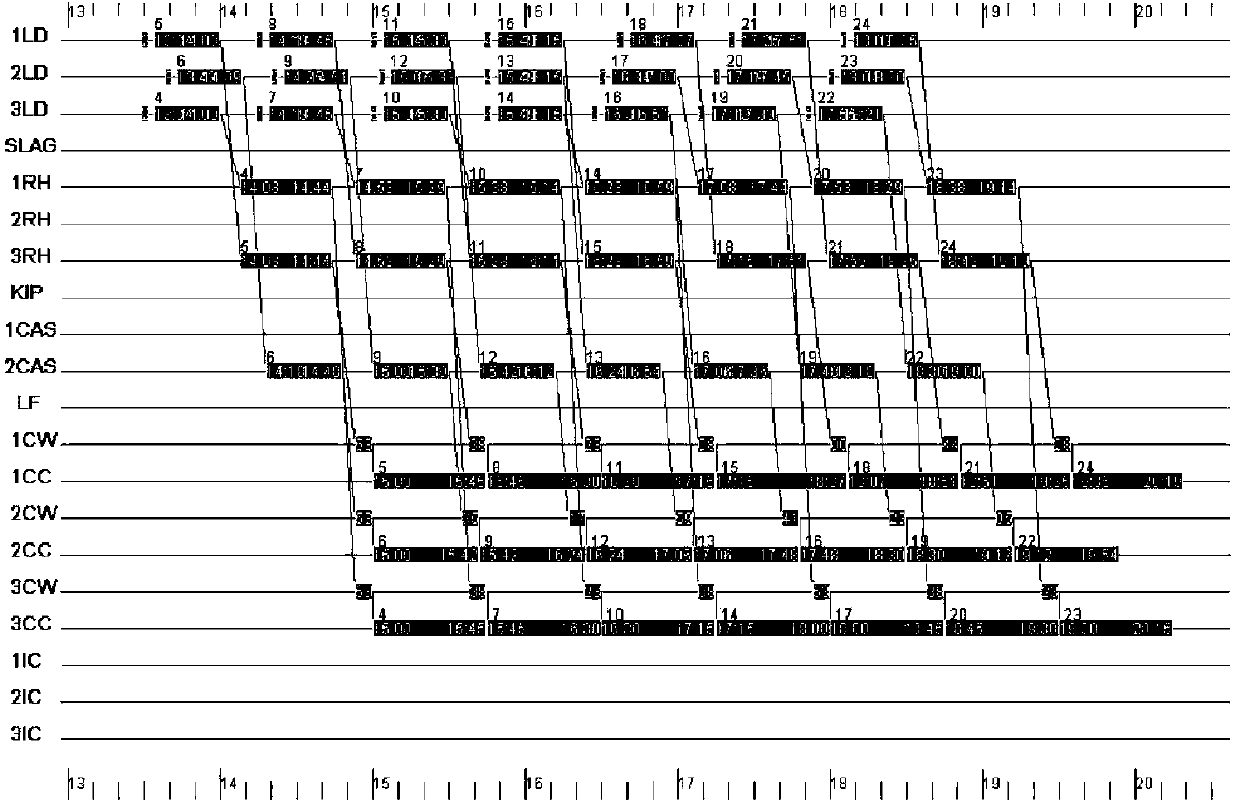

[0066] The specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment takes the actual production scheduling problem of a certain iron and steel enterprise as an example. The production line includes: 3 converters (1LD, 2LD, 3LD), refining equipment (1RH, 2RH, 3RH , 1CAS, 2CAS, KIP, LF), 3 continuous casting (1CC, 2CC, 3CC).

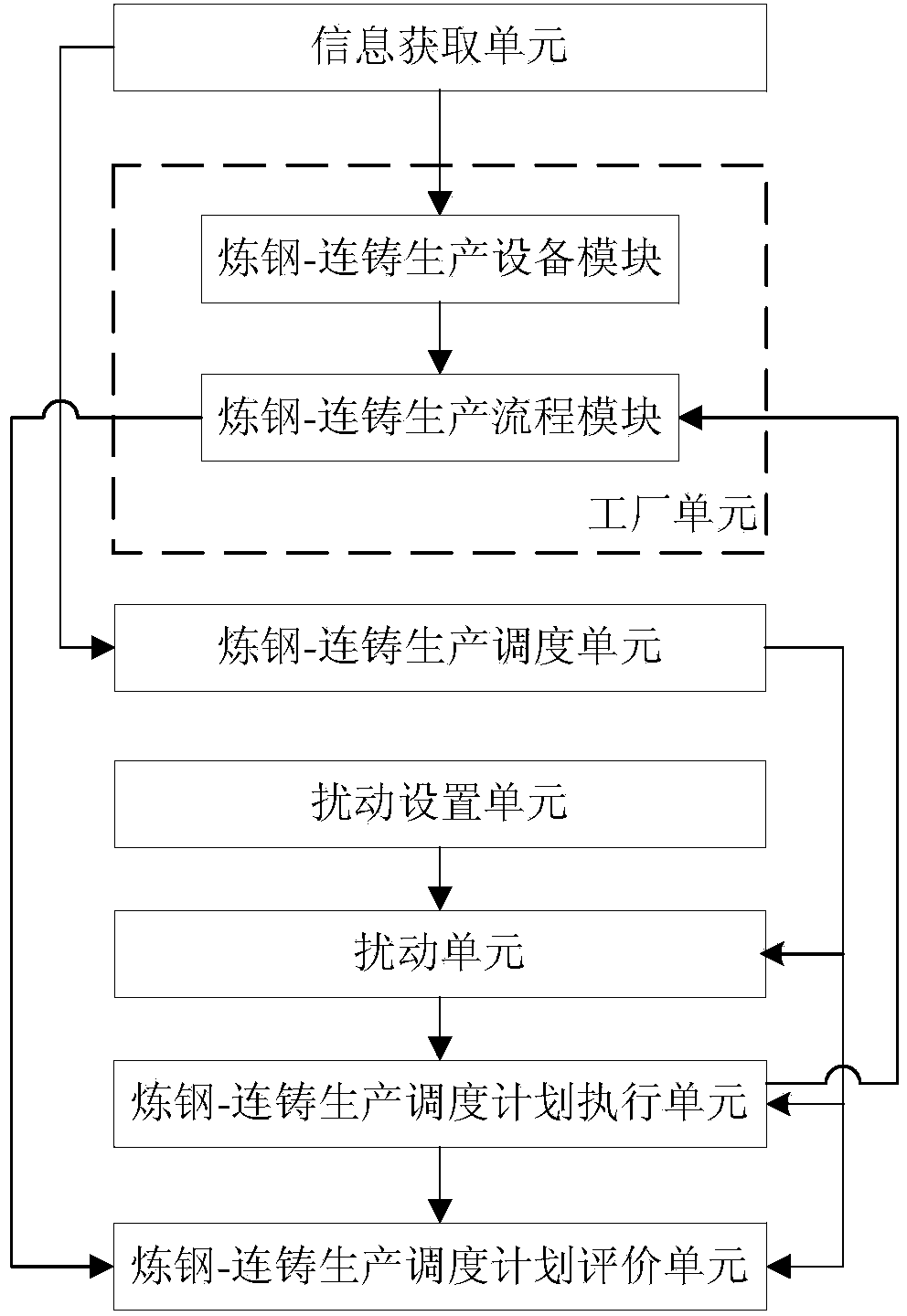

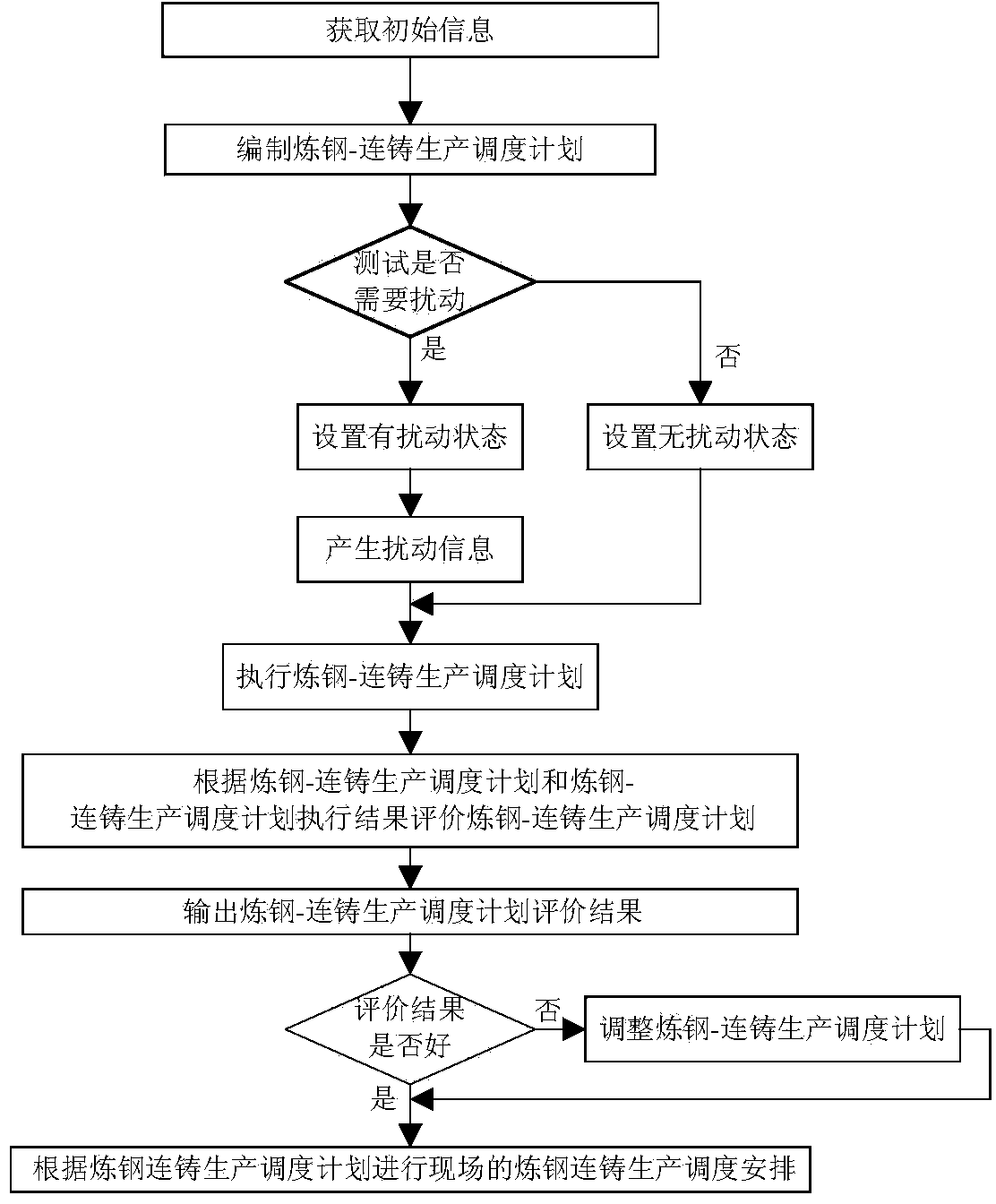

[0067] Such as figure 1 As shown, the scheduling system of steelmaking-continuous casting production in this embodiment includes:

[0068] Information acquisition unit: used to obtain the basic information of the factory's steelmaking-continuous casting production equipment and the factory's steelmaking-continuous casting production plan information; the basic information of the factory's steelmaking-continuous casting production equipment includes: the type of equipment in the factory, the total number of each type of equipment , the processing time of each equipment and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com