On-line dynamic dispatching method for continuous steel casting production

A technology of dynamic scheduling, steelmaking and continuous casting, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as dynamic scheduling problems that do not involve steel production, and achieve the effect of reducing blindness and unscientificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

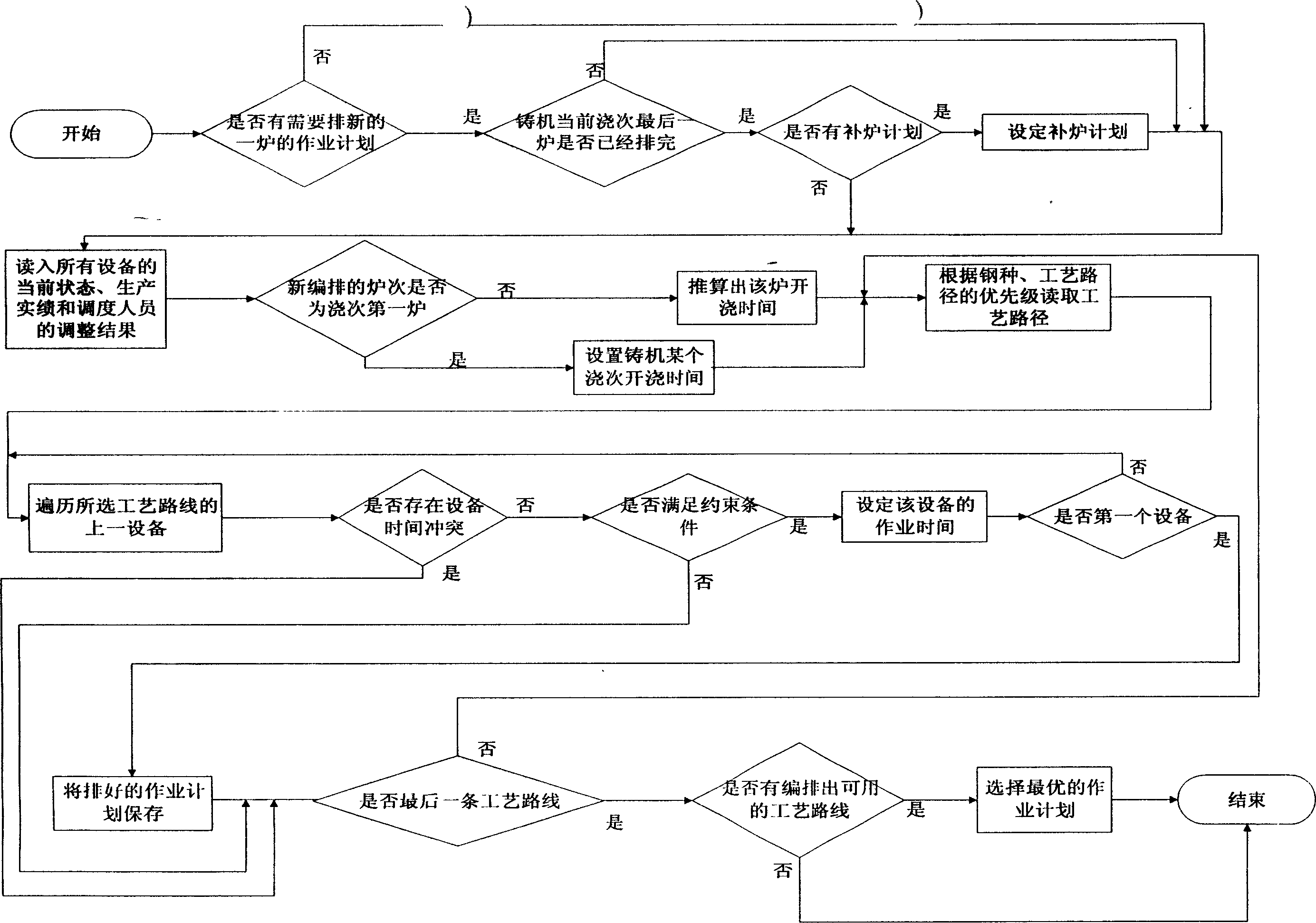

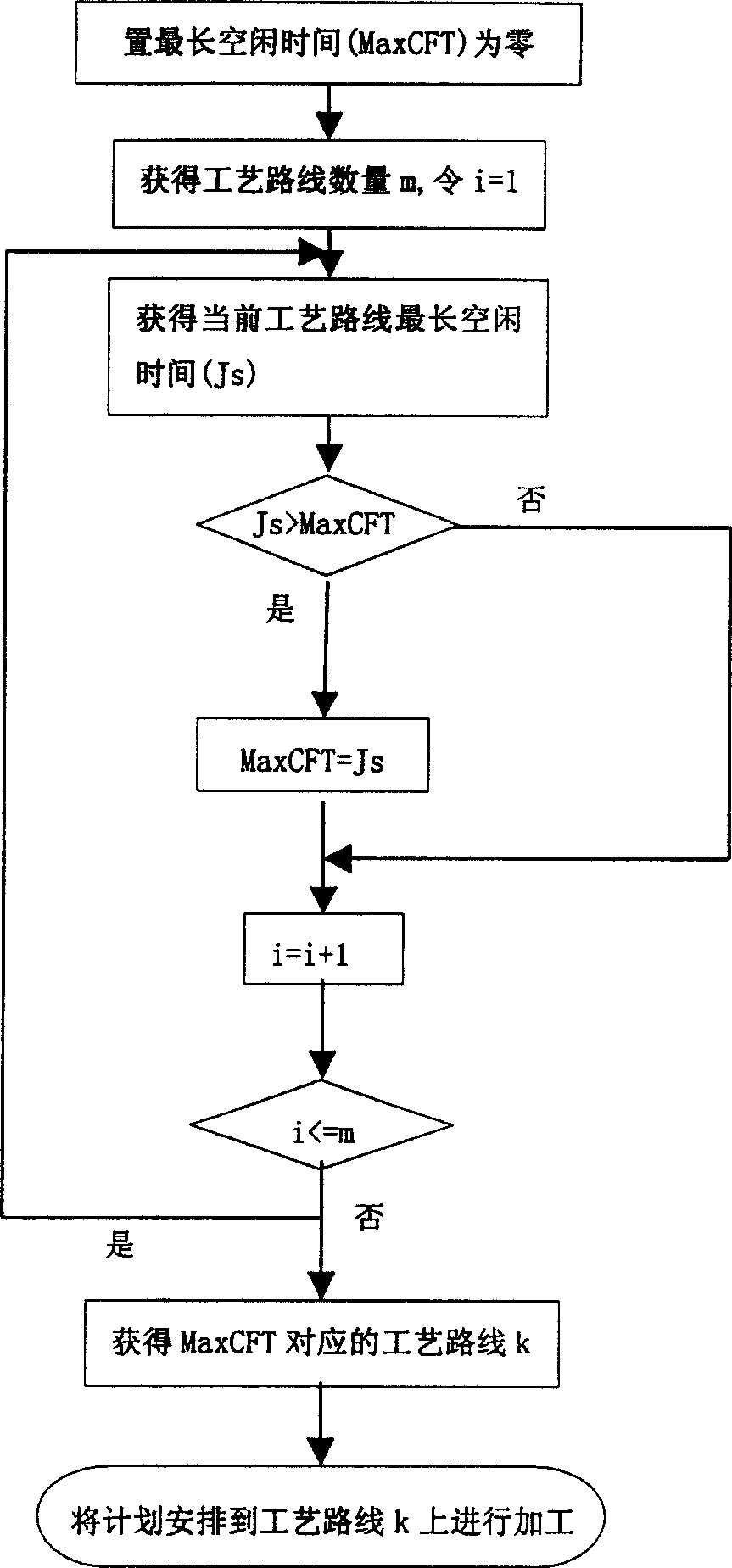

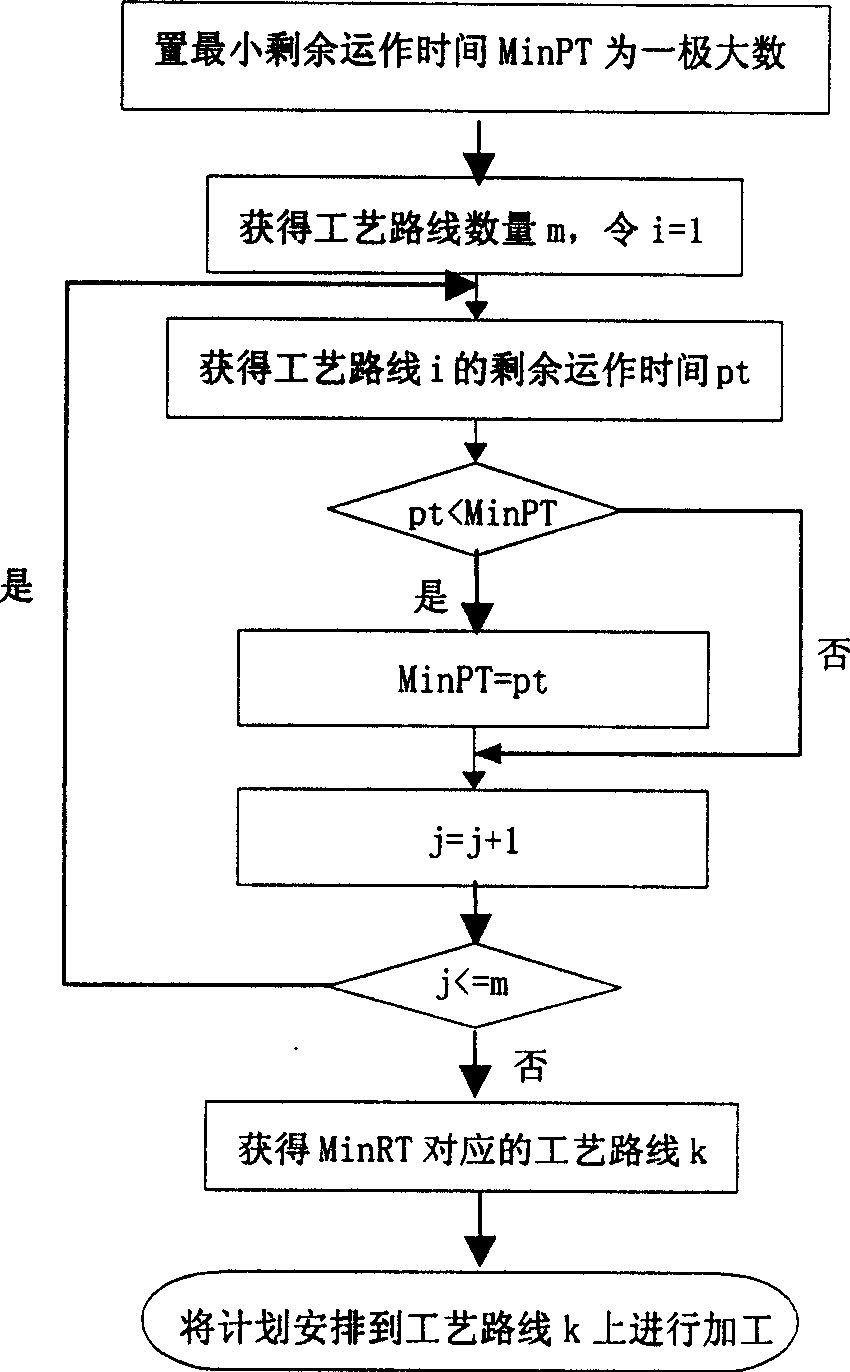

Method used

Image

Examples

Embodiment Construction

[0109] In the following, a steelmaking and continuous casting production line is taken as an example to illustrate that under normal and abnormal conditions, the present invention can dynamically schedule and direct production on-line according to the actual conditions of the production site. The production line includes: 3 converters, 3 refining positions, 2 LF furnaces, 1 VD furnace, 4 continuous casting

[0110] Normal situation: Assuming that the 2# converter, 2# and 4# continuous casting machines are in a scheduled repair state at 10:20 at the current time, and the 4# continuous casting machine will end the maintenance at 11:00. A furnace of molten steel with the heat number 109 is cast in the 1# continuous casting machine, and the system automatically triggers the scheduling of the operation plan.

[0111] 1. Set the pouring time of the continuous casting machine. First, it is judged that the current casting of No. 1 continuous casting machine has been arranged to the last f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com