Energy-saving continuous operation inclined plane sintering machine

A sintering machine, energy-saving technology, used in furnace types, furnaces, lighting and heating equipment, etc., can solve the problems of continuous production, high operating costs, and the production line is stopped and turned on and off. It can reduce configuration, ensure sealing, and reduce consumption. Can less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

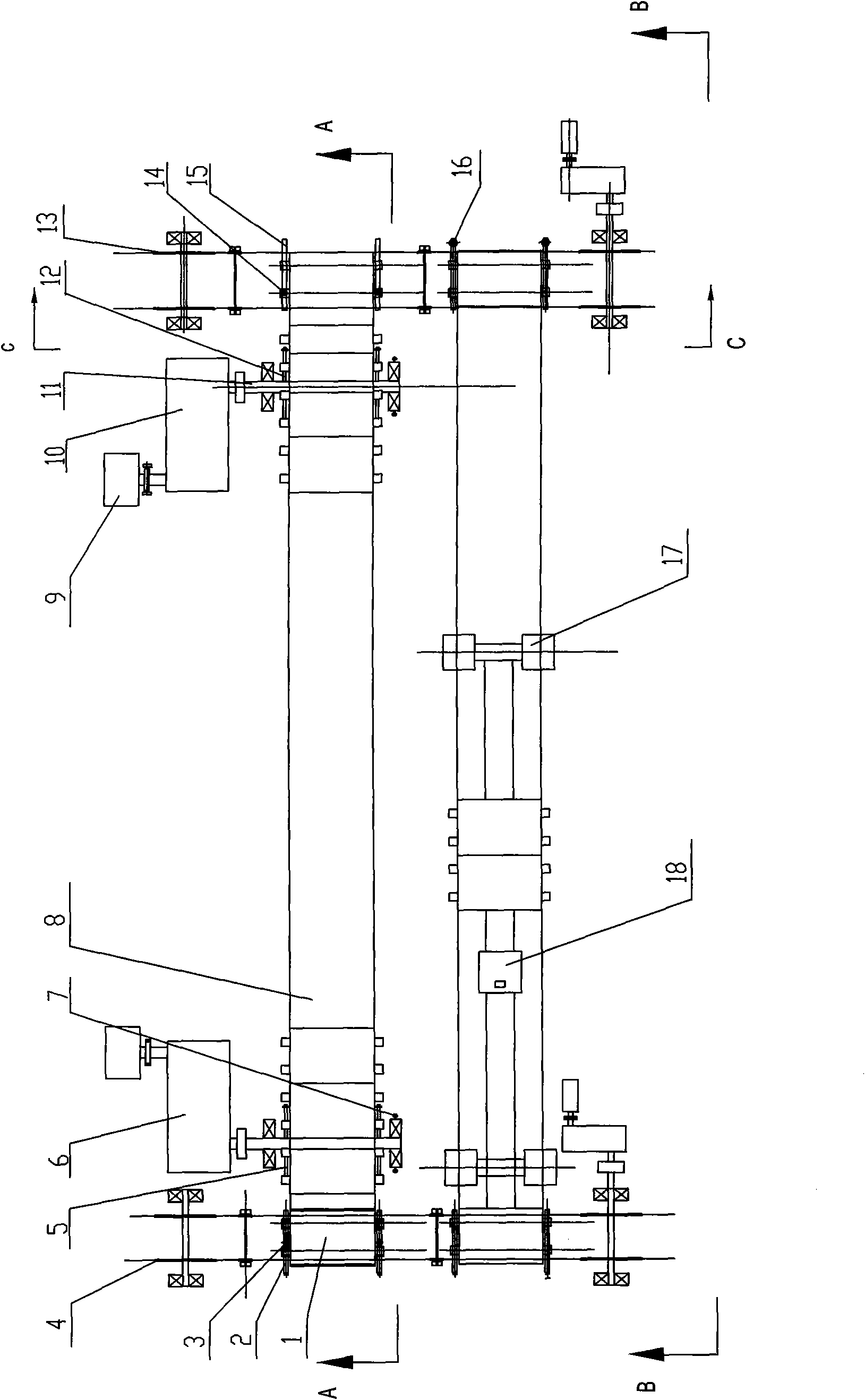

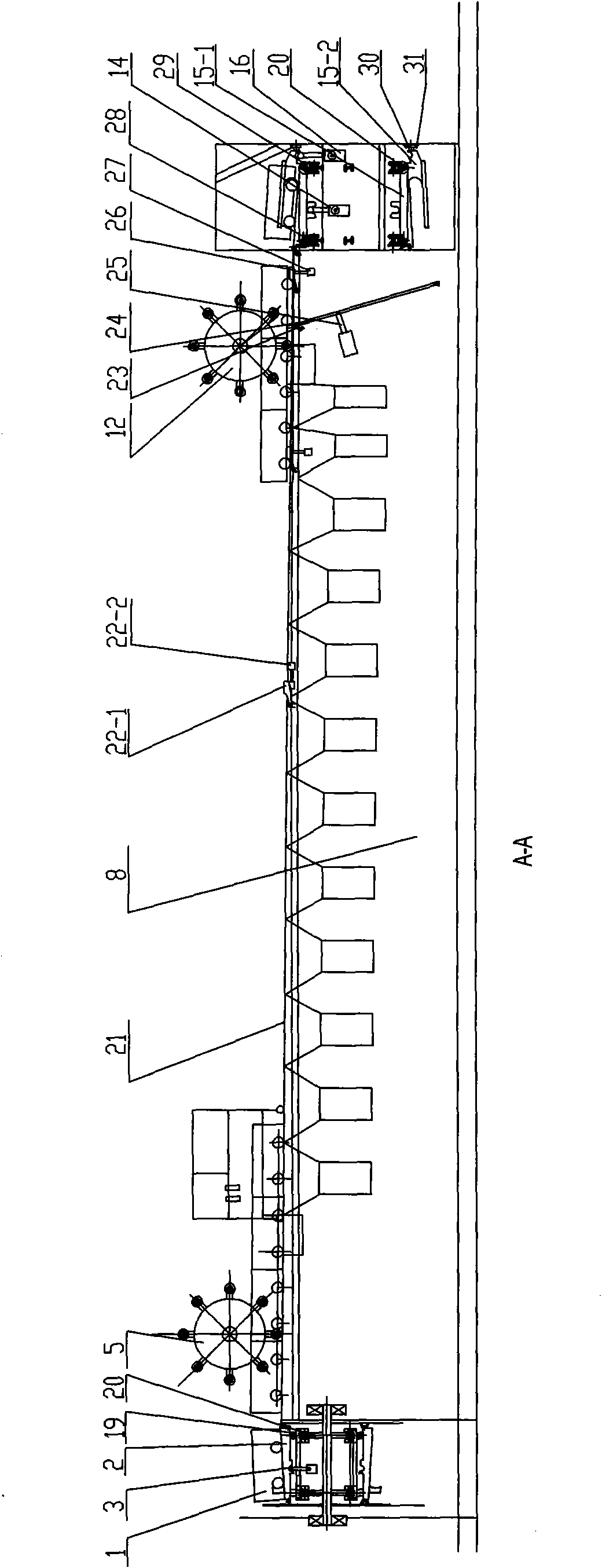

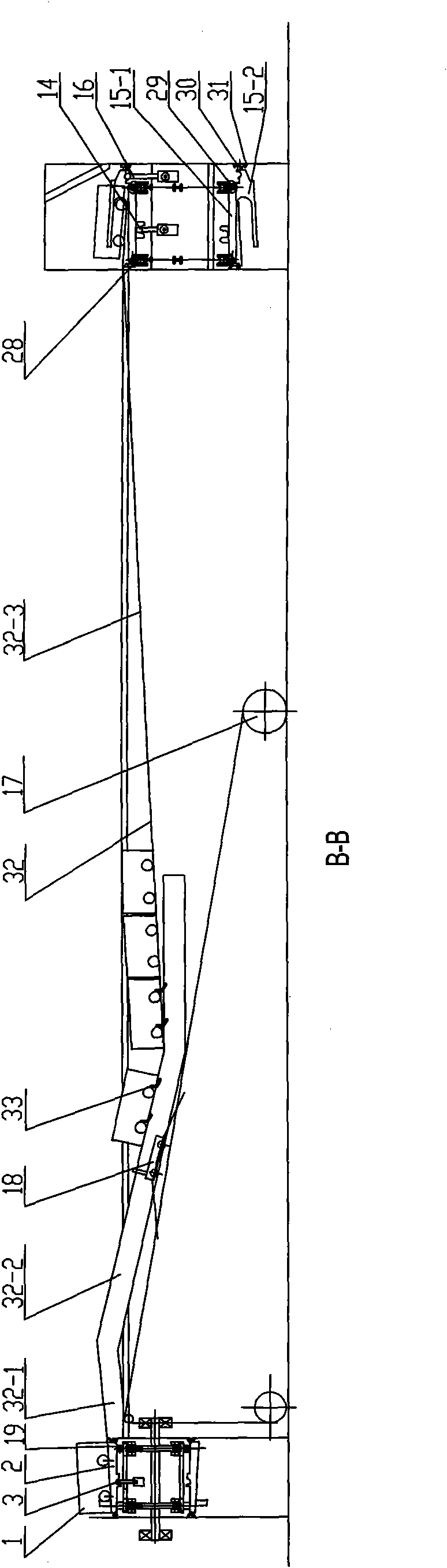

[0033] The specific implementation of the present invention will be further described below with reference to the embodiments given in the drawings.

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, an energy-saving continuous-running inclined surface sintering machine of the present invention includes a sintering machine body 8, a head chain conveyor 4, a tail chain conveyor 13, a trolley return system, and is arranged in the sintering machine The driving mechanism 5 of the body head and the trolley 1. The trolley return system includes a bracket, a trolley return rail 32 arranged on the bracket, a hoisting mechanism 17 arranged below the trolley return rail 32, and this The traction trolley 18 connected to the hoisting mechanism 17 is characterized in that the trolley rail 21 is arranged with a high feeding end and a low slant setting at the outlet end. A damping mechanism 12 is provided at the tail of the sintering machine body 8, and Both the driving mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com