Spring drive device for three-position switching operating mechanism

An operating mechanism and spring-driven technology, applied to the power device inside the switch, contact operating mechanism, electric switch, etc., to achieve the effects of facilitating production organization, simple and practical operation, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

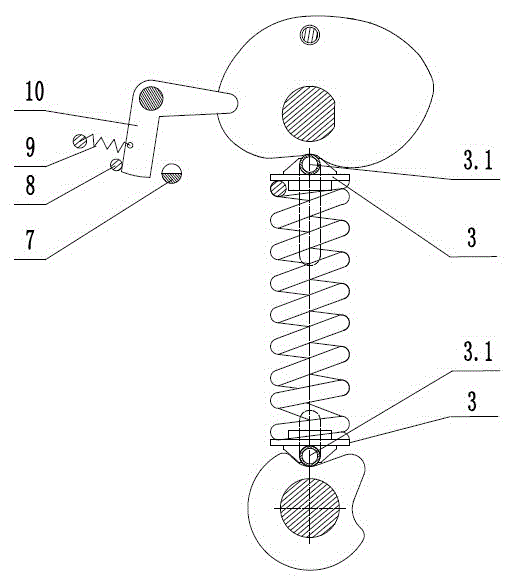

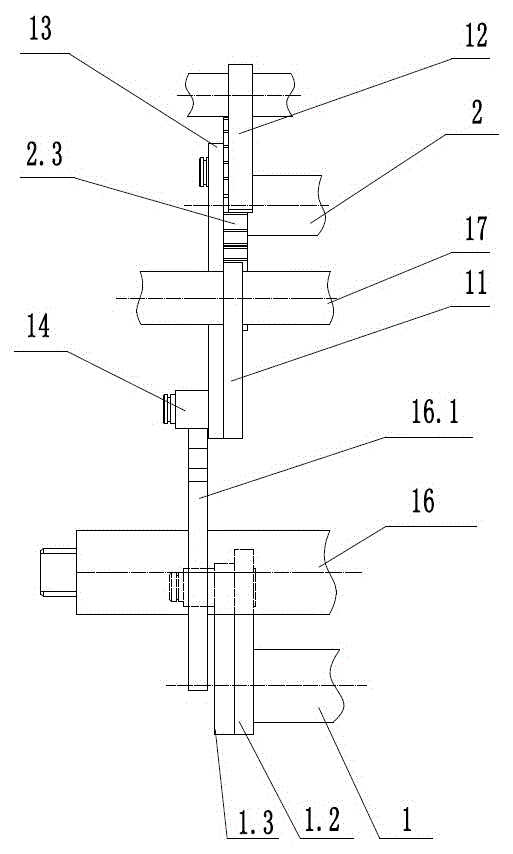

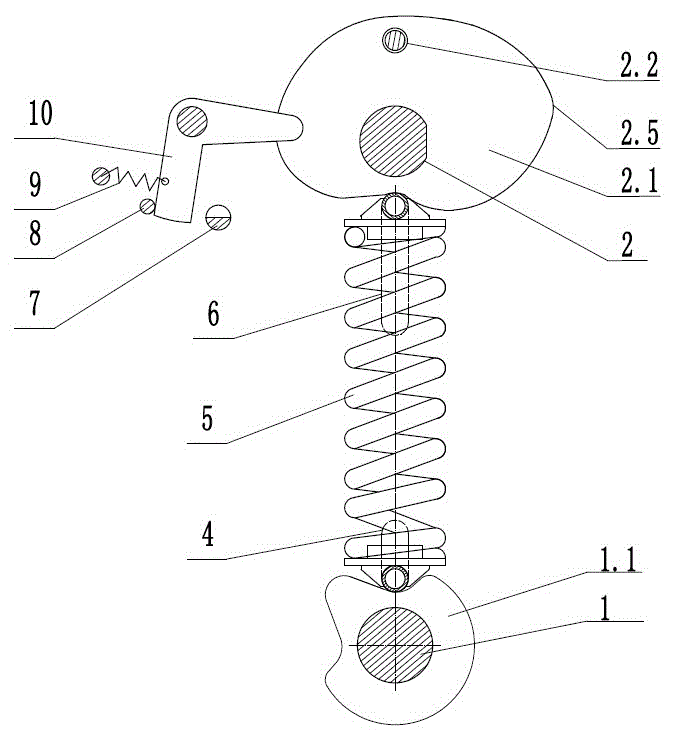

[0023] Embodiment 1: A spring driving device of a three-position switch operating mechanism, including a front plate, a middle plate, a rear plate and its support column for fixing and supporting, a grounding operation shaft 1, a switch operation shaft 2, and an output shaft 16 runs through the front plate, the middle plate and the rear plate, and the rotating shaft 17 is fixed on the middle plate. The switch operation shaft 2 and the grounding operation shaft 1 are vertically distributed, the closing spring 5 is located in the middle of the switch operation shaft 2 and the grounding operation shaft 1, and the grounding operation shaft 1 is provided with two grounding devices located symmetrically between the front plate and the middle plate. Cam 1.1, driving plate 1.2 and driving crank arm 1.3 located between the middle plate and the rear plate, two closing cams 2.1, cam rollers 2.2 and ratchets arranged symmetrically between the front plate and the middle plate on the switch ...

Embodiment 2

[0025] Embodiment 2: The hanging spring arm 1.5 replaces the grounding cam 1.1, the grounding limit block 19 and the opening limit block 18 replace the two grooves on the grounding cam 1.1, and the hanging spring seat 20 replaces the spring seat connected to the grounding cam 1.1 3. The shaft pin 21 replaces the spring seat roller 3.1 to realize the grounding and opening operation of the grounding switch. The hanging spring seat 20 is connected with the hanging spring crank arm 1.5 by a pivot pin 21. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com