Continuous casting data space-time matching method based on heat tracking and casting flow tracking

A matching method and technology of heats, applied in the field of steelmaking and continuous casting, can solve the problems of inability to reflect the impact and inability to accurately manage the quality of slabs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

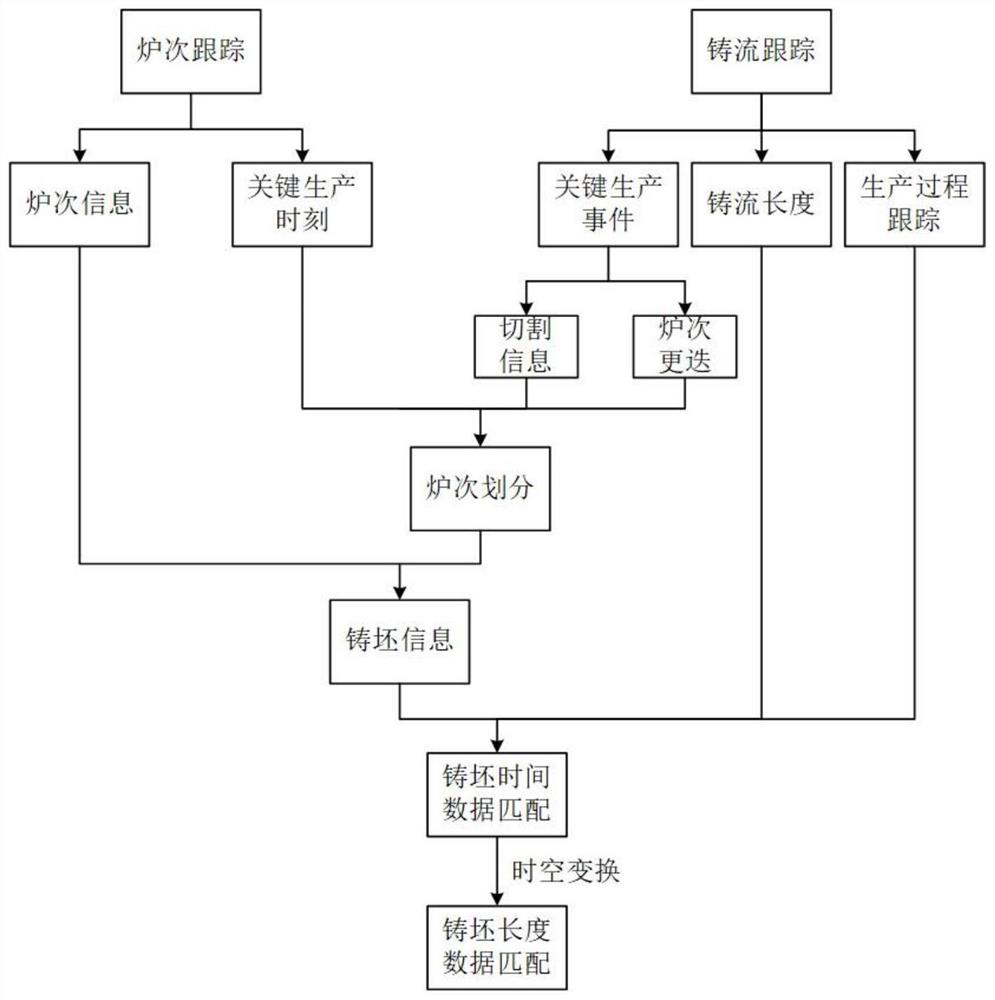

Method used

Image

Examples

Embodiment 1

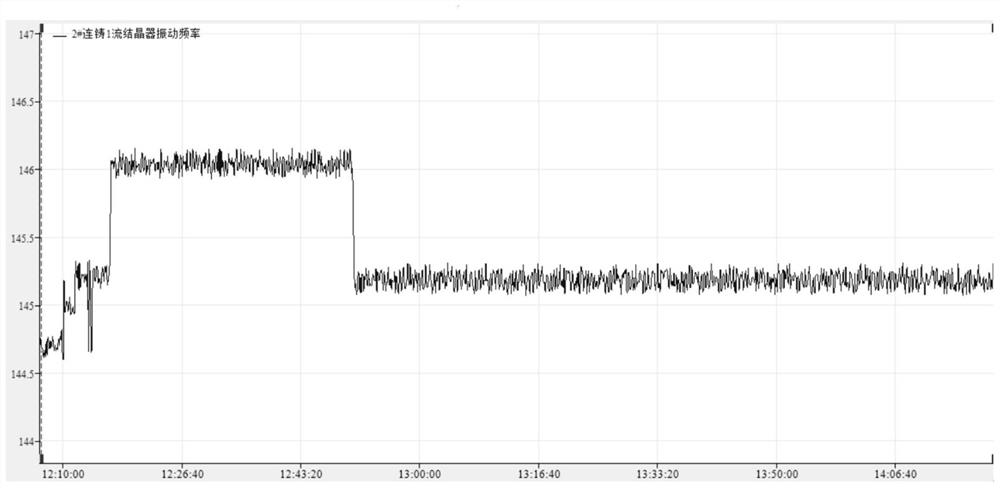

[0055] Taking the production situation of two heats mixed casting in a continuous casting production line as an example, the key data in the continuous casting process and the width and thickness of the crystallizer were obtained from the site, as shown in Table 1. And the actual concentrations and allowable ranges of molten steel in two heats were obtained from the site, as shown in Table 2. The distance from each equipment of the continuous casting machine to the cutting device was also obtained from the site, as shown in Table 3.

[0056] Table 1 Key information of continuous casting site tracking process

[0057]

[0058] Table 2 Composition data of molten steel in continuous casting site

[0059]

[0060]

[0061] Table 3 Distance from each device of continuous casting machine to cutting device

[0062]

[0063]

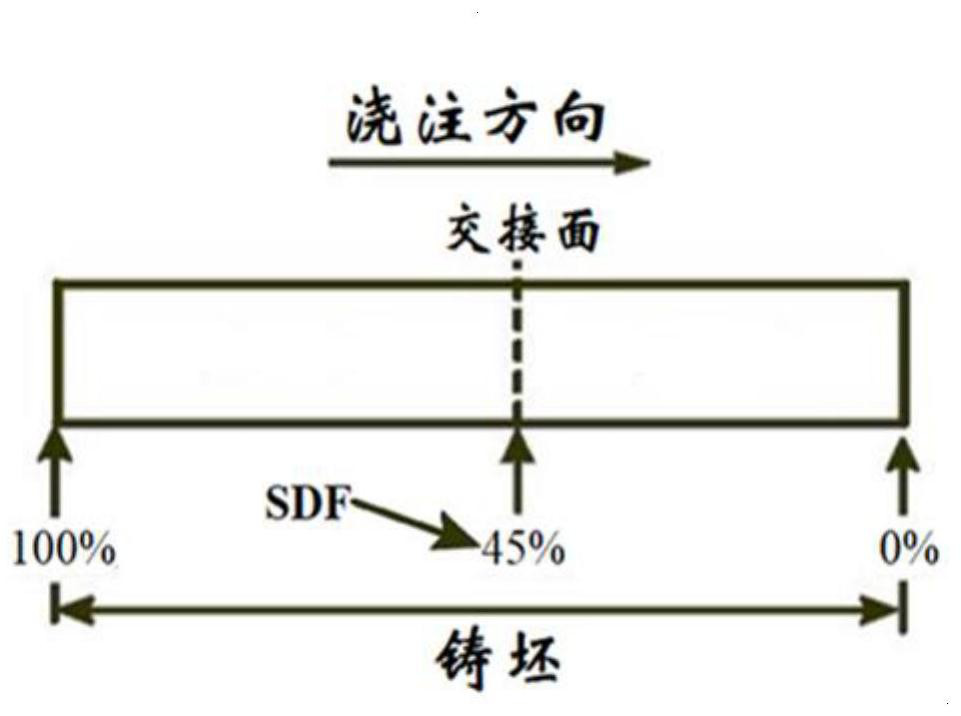

[0064] According to these data, the present invention is used to match the time and space of the continuous casting production data and the sla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com