Steelmaking square billet encoding and sizing method

A technology of sizing and coding, which is applied in the field of coding and sizing of steelmaking billets, to achieve the effects of improving service life, good practical value and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

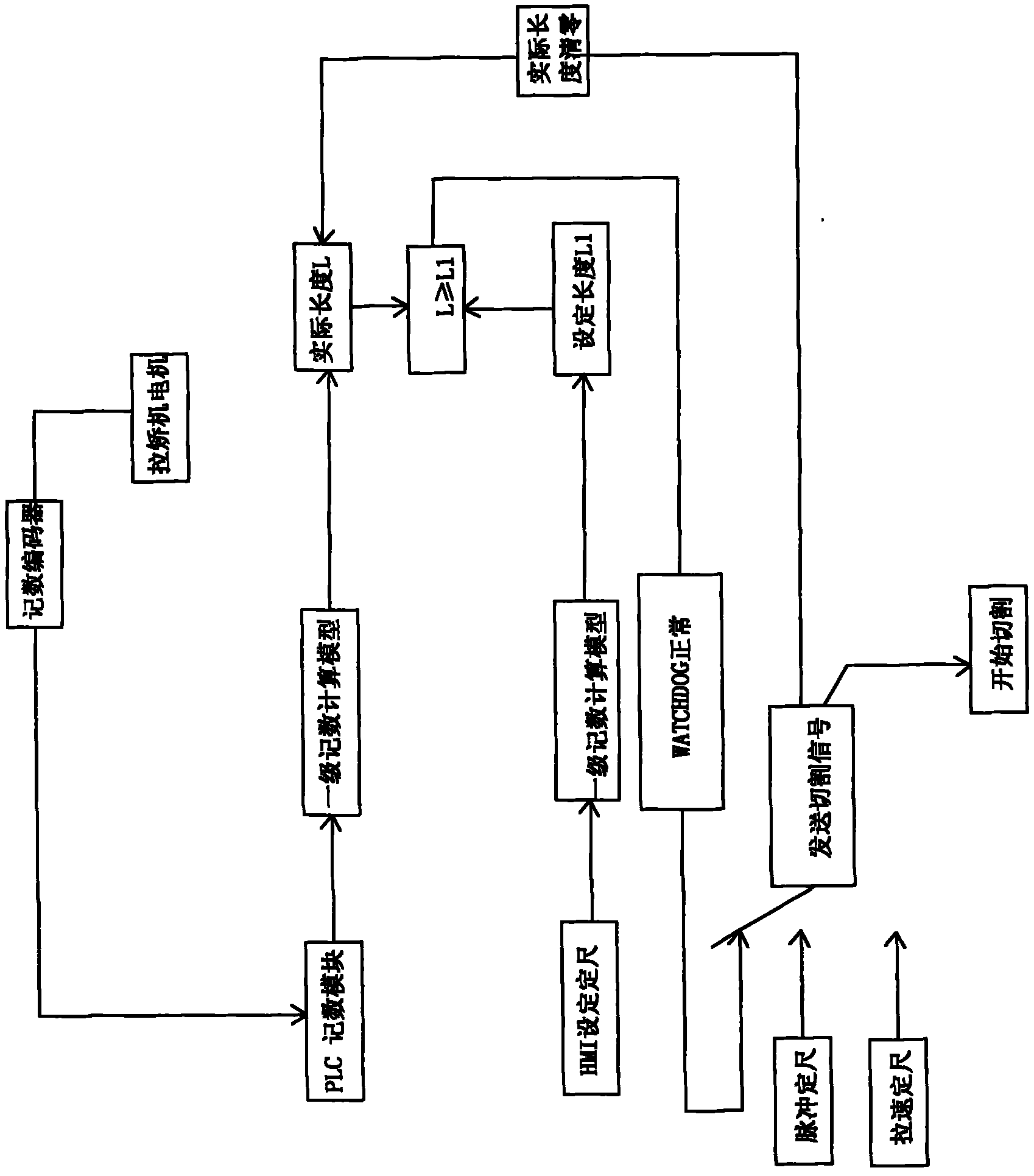

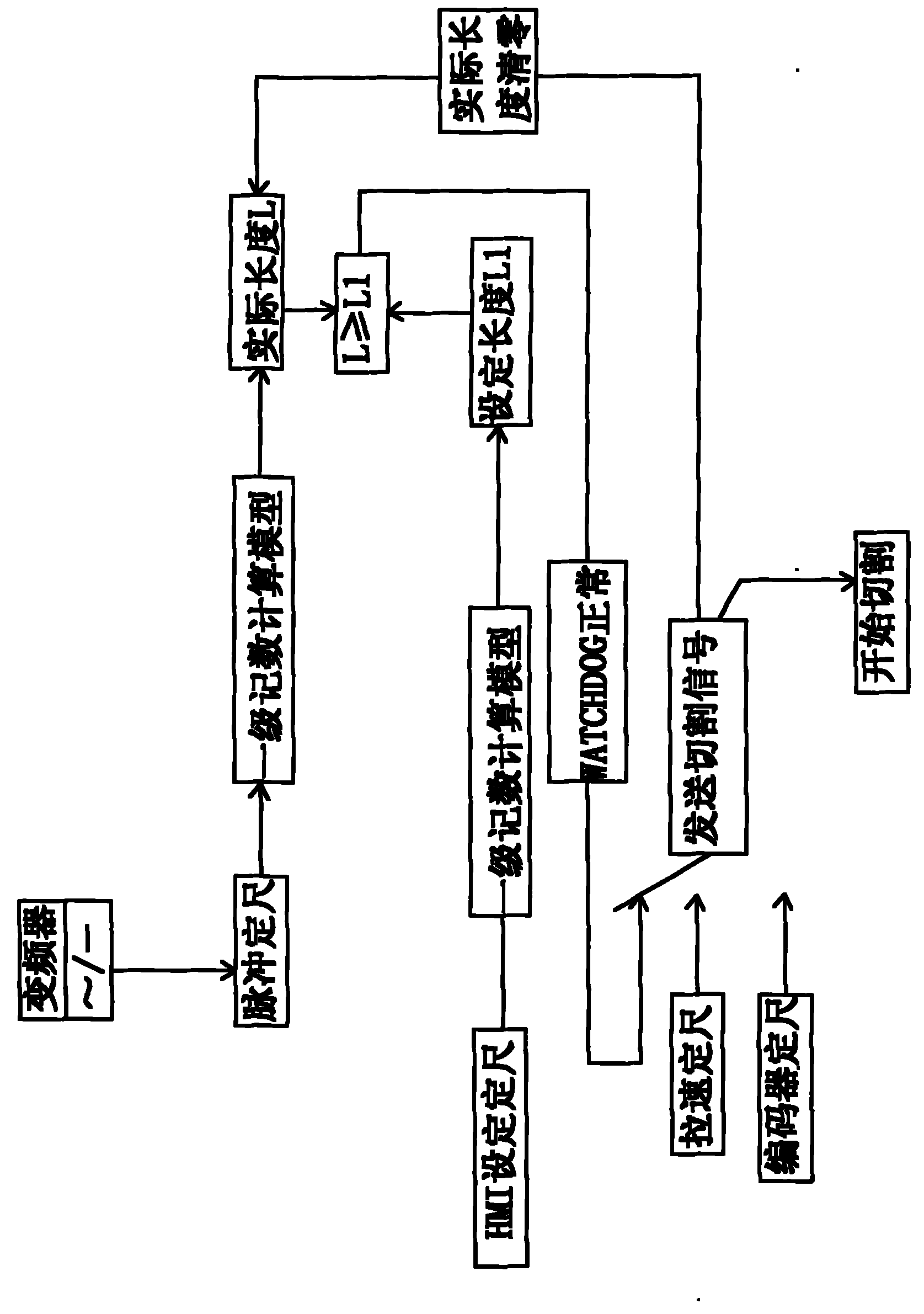

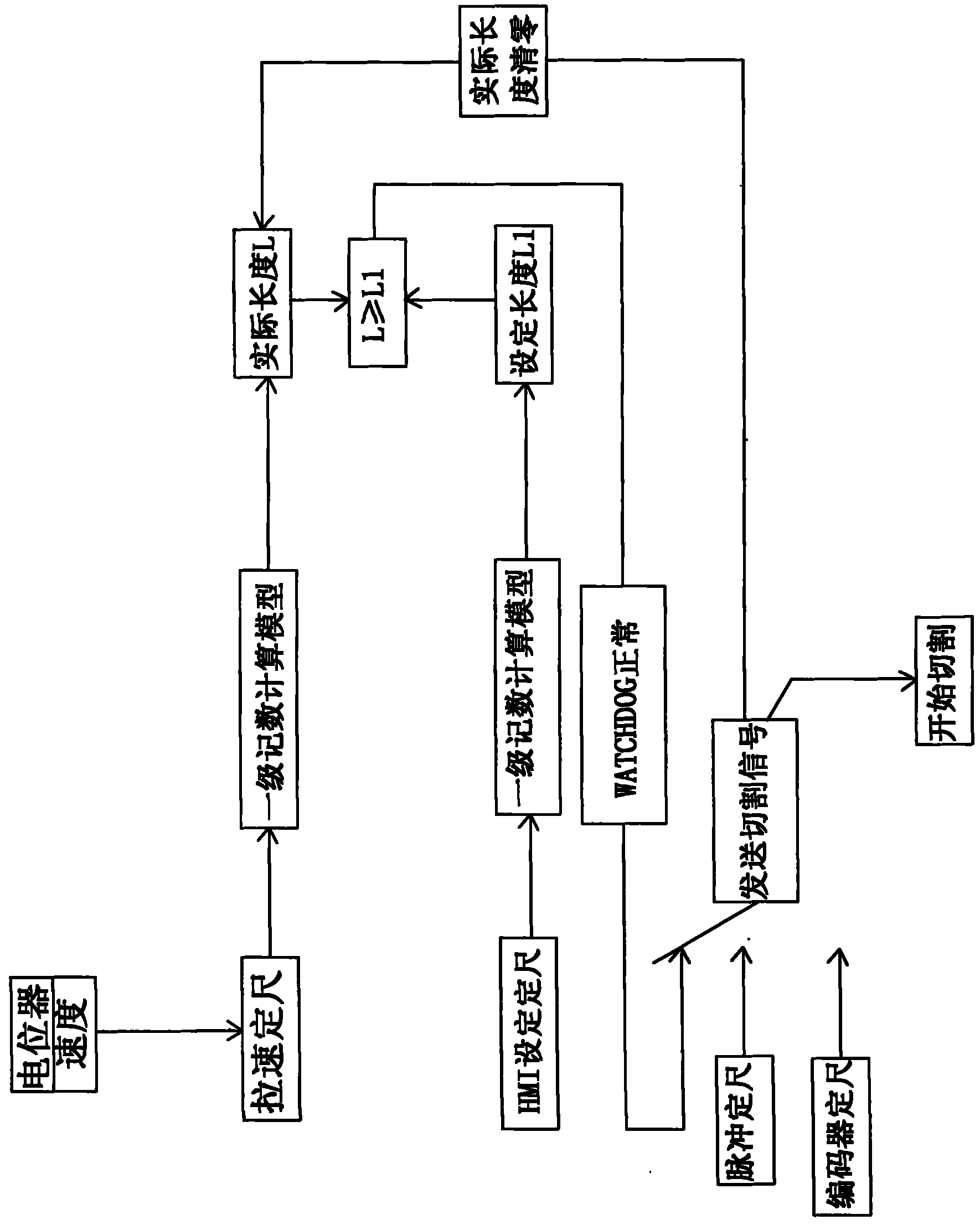

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0011] In the steelmaking billet encoding and sizing method described in this embodiment, first, an incremental rotary encoder is added to the upper roll of the tensioning and leveling machine, and the tensioning and leveling roll is used as a measuring roll for data tracking and measurement. 1 pulse actual billet running distance = ∏D (drawing and straightening roll diameter) N (reduction ratio) ÷ n (encoder actual pulse number).

[0012] In order to improve the service life of the encoder, a water-cooled sheath is added to the encoder, so that the operating environment temperature of the encoder is 70°C. The connection method adopts spring type soft connection to prevent the motor bearing heat conduction from affecting the encoder operation. The encoder cable is equipped with a heat-resistant sleeve to prevent heat from affecting the encoder's tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com