Control method for typical middle cracks and center segregation during pipeline steel slab continuous casting

A control method and technology for steel slabs, applied in the field of steelmaking and continuous casting, can solve the problems of inaccurate reduction position, poor improvement of center segregation, and influence on the effect of light reduction, so as to improve accuracy, improve control level, reduce Effect of Small Intermediate Crack Defect Incidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

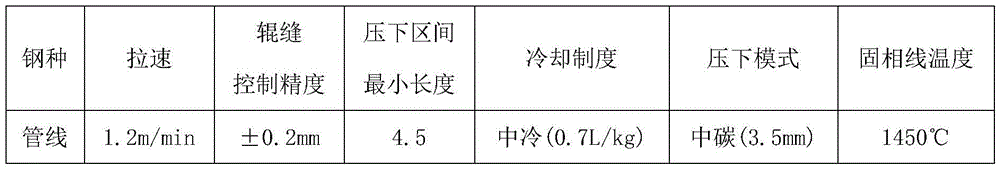

[0024] Scanning electron microscope energy spectrum analysis was carried out on the cracks in the middle of a typical pipeline steel slab, and there were obvious segregation of Nb, S and other elements in the cracks, resulting in a decrease in thermoplasticity. Under complex stress conditions, the local maximum principal strain exceeds the local critical strain, which in turn leads to the occurrence of the above-mentioned intermediate cracks. Therefore, in order to reduce the stress and strain at the solidification front near the triangular area, the continuous casting process route formulated is shown in Table 2 below. In the down mode, the casting machine presses down the segment into 8 and 9 segments. Tracking the historical data of the displacement sensor of the oil cylinder in the segment within the billet reduction range, the reductions of the two segments in the reduction range are more uniform, and the reduction rates are 1.2mm / m and 0.7mm / m respectively. , eliminatin...

Embodiment 2

[0028] In order to ensure the equipment conditions of the soft reduction process, the off-line maintenance calibration and prior inspection of the sector are strictly required to ensure that the roll gap control accuracy is ±0.2mm. According to the reduction control principle of the casting machine, the length of the theoretical reduction interval is increased to 4.5m, and the solidus temperature is revised to 1450°C. The accuracy of the reduction position is guaranteed, and the maximum reduction rate in a single segment is reduced. The basic roll gap curve of the casting machine is: the central liquid phase area is 0.39, the central two-phase area is 0.21, and the central solidification area is 0.11; The curves in the table below are three-stage reductions, and the reduction rates are 0.7mm / m, 1.0mm / m, and 0.25mm / m. Track the internal quality of the slab, center segregation, and the proportion of Class C ≤ 1.0 has been greatly increased from 45% to 87%.

[0029] Table 3 cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com