Quick and thinning stamping processing new energy automobile battery shell steel and method for producing same

A new energy vehicle, stamping technology, applied in the field of metallurgy, can solve the problems of poor forming performance of battery shell steel, and achieve the effect of high cleanliness, high forming performance characteristics, high performance uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

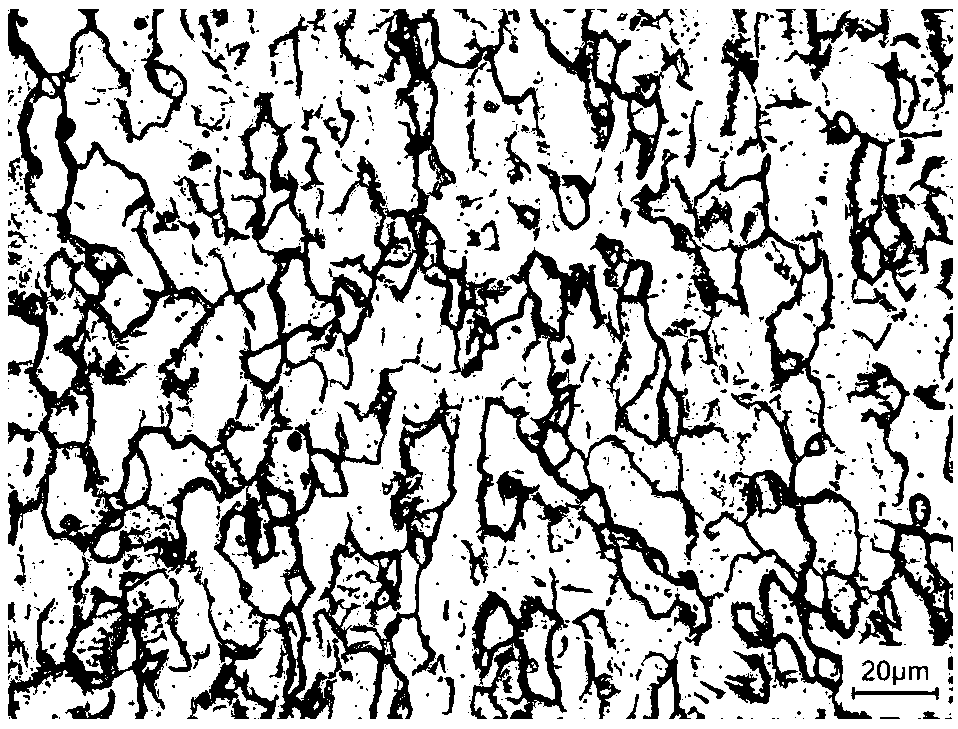

Embodiment 1

[0052] See Table 1 for the chemical composition and mass percentage of the steel for the battery shell of the new energy vehicle that is processed by rapid, thinning and stamping in this embodiment.

[0053] The production method of the steel for the battery shell of a new energy vehicle by rapid, thinning and stamping processing in this embodiment includes the steps of steelmaking, continuous casting, hot rolling, coiling, cold rolling, continuous annealing, and leveling, and the specific process steps are as follows:

[0054] (1) Steelmaking process: Before smelting, molten iron is subjected to compound injection of lime and magnesium powder for deep desulfurization treatment, molten iron S: 0.003%; converter smelting terminal temperature 1700℃, terminal oxygen level 485ppm, molten steel composition: C: 0.045%, S: 0.005%, P: 0.009%; the molten steel discharged from the converter is subjected to vacuum treatment by RH, and the RH vacuum treatment process is followed by decarbu...

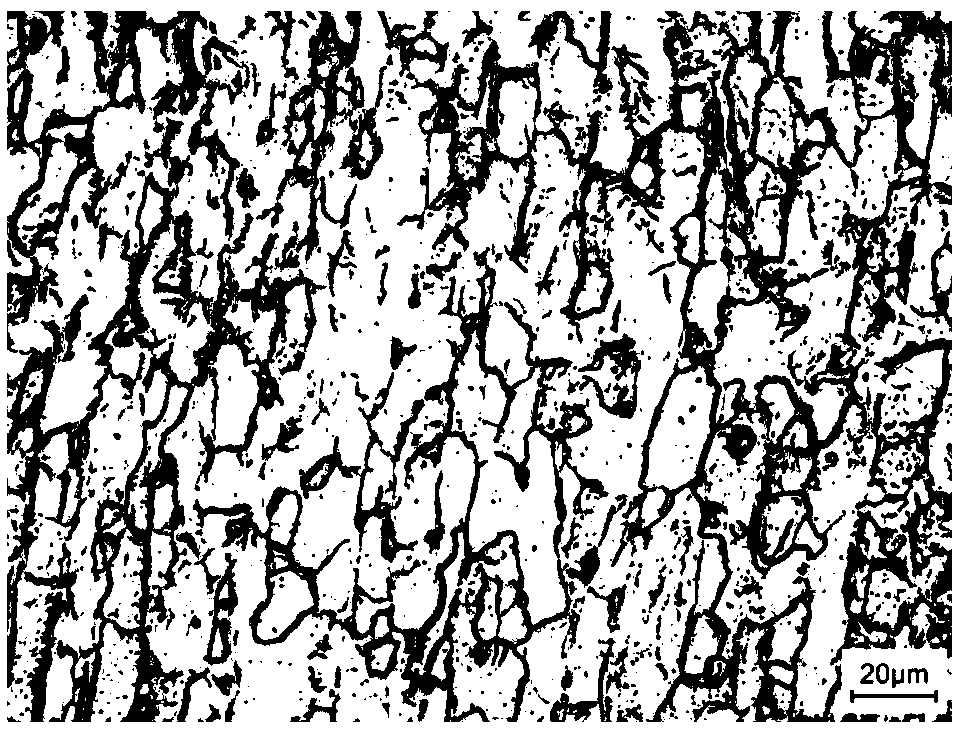

Embodiment 2

[0063] See Table 1 for the chemical composition and mass percentage of the steel for the battery shell of the new energy vehicle that is processed by rapid, thinning and stamping in this embodiment.

[0064] The production method of the steel for the battery shell of a new energy vehicle by rapid, thinning and stamping processing in this embodiment includes the steps of steelmaking, continuous casting, hot rolling, coiling, cold rolling, continuous annealing, and leveling, and the specific process steps are as follows:

[0065] (1) Steelmaking process: Before smelting, molten iron is subjected to compound injection of lime and magnesium powder for deep desulfurization treatment, molten iron S: 0.002%; converter smelting terminal temperature 1703 °C, terminal oxygen level 550ppm, molten steel composition: C: 0.040%, S: 0.007%, P: 0.010%; the molten steel from the converter is vacuum treated by RH, and the RH vacuum treatment process is followed by decarburization, deep deoxidati...

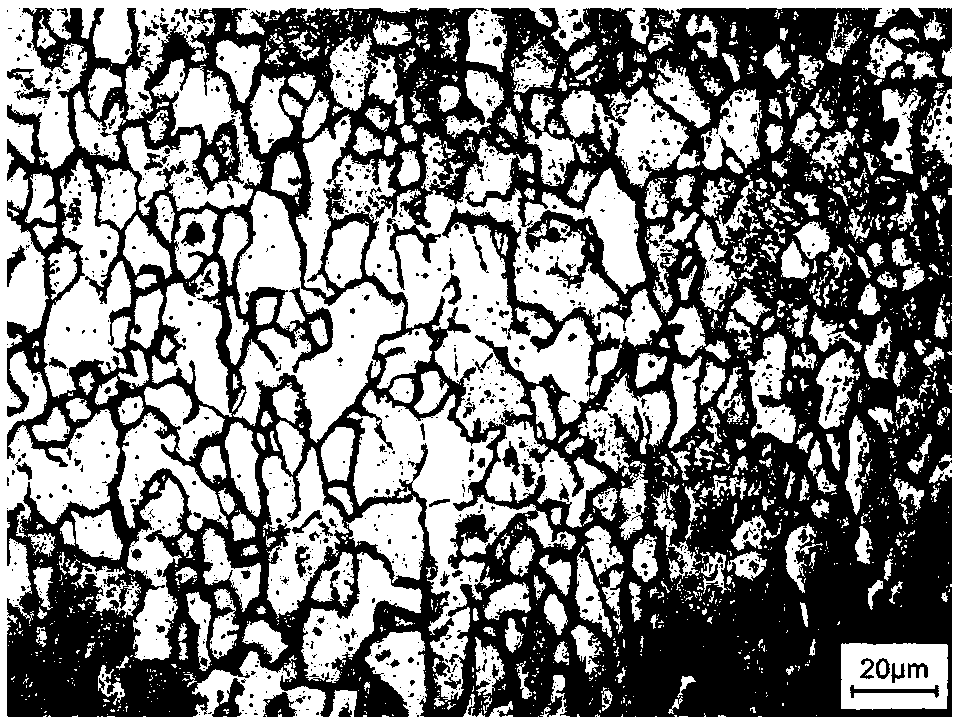

Embodiment 3

[0074] See Table 1 for the chemical composition and mass percentage of the steel for the battery shell of the new energy vehicle that is processed by rapid, thinning and stamping in this embodiment.

[0075] The production method of the steel for the battery shell of a new energy vehicle by rapid, thinning and stamping processing in this embodiment includes the steps of steelmaking, continuous casting, hot rolling, coiling, cold rolling, continuous annealing, and leveling, and the specific process steps are as follows:

[0076] (1) Steelmaking process: Before smelting, molten iron is subjected to compound injection of lime and magnesium powder for deep desulfurization treatment, molten iron S: 0.001%; converter smelting end temperature 1730℃, end oxygen level 750ppm, molten steel composition: C: 0.035%, S: 0.004%, P: 0.013%; the molten steel out of the converter is vacuum treated by RH, and the RH vacuum treatment process is followed by decarburization, deep deoxidation by ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com