Novel papermaking wet part deformer

A technology of defoamer and wet end, which is applied in the field of preparation of new paper-making wet end defoamer, and can solve problems such as harmful foam

Active Publication Date: 2010-02-03

JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

View PDF9 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0009] The purpose of this invention is to provide a new type of wet-end defoamer to solve the problem of harmful foam in paper production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 2

[0043] Example 2: Preparation of polyether

[0044] R 2

example 3

[0045] Example 3: Preparation of modified polyether

[0046] R 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| cloud point | aaaaa | aaaaa |

| cloud point | aaaaa | aaaaa |

Login to View More

Abstract

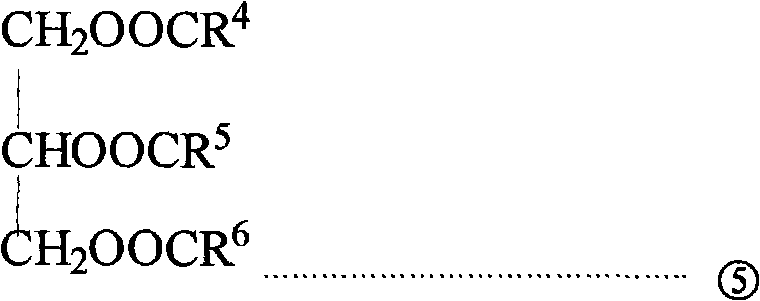

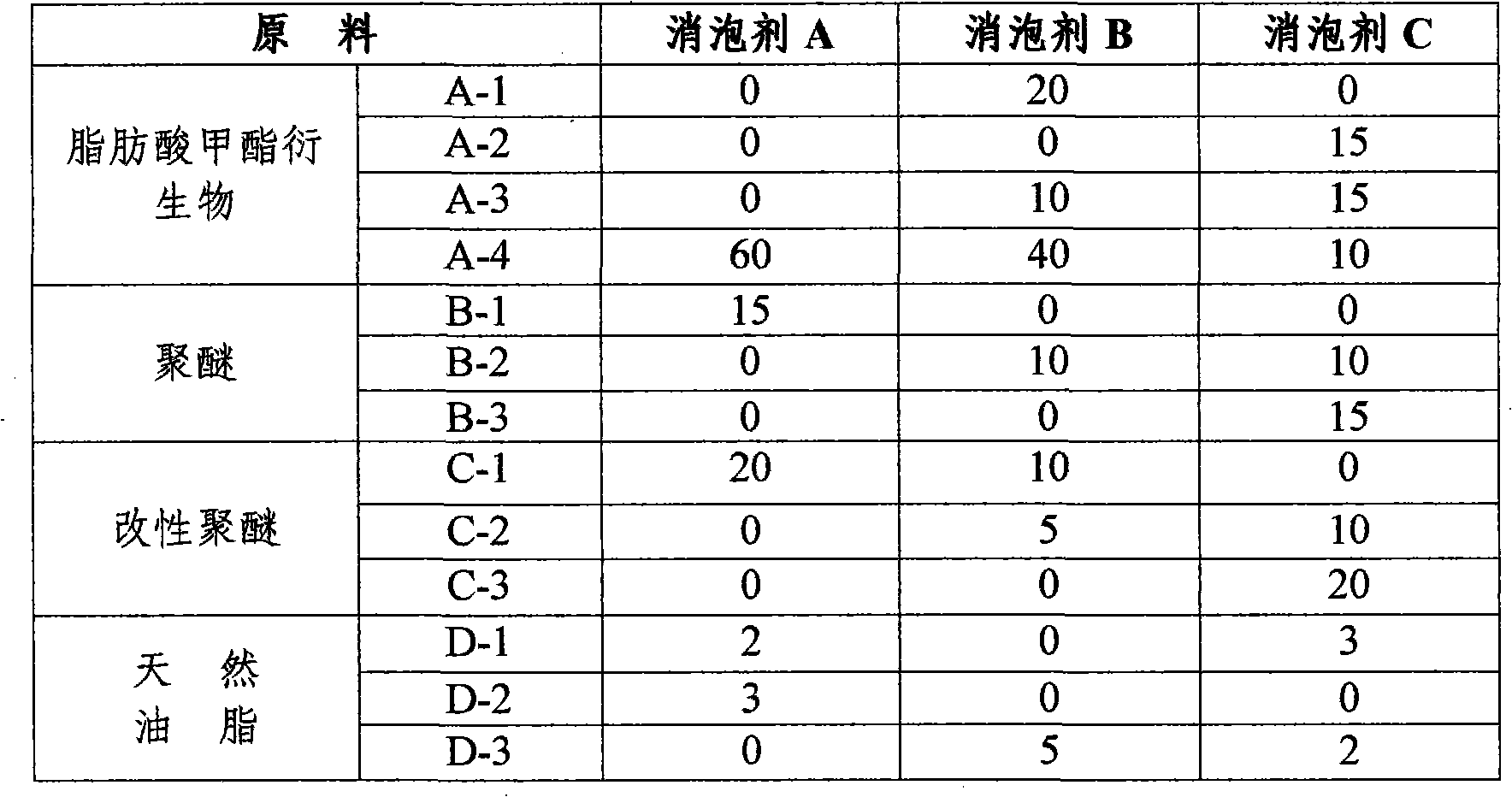

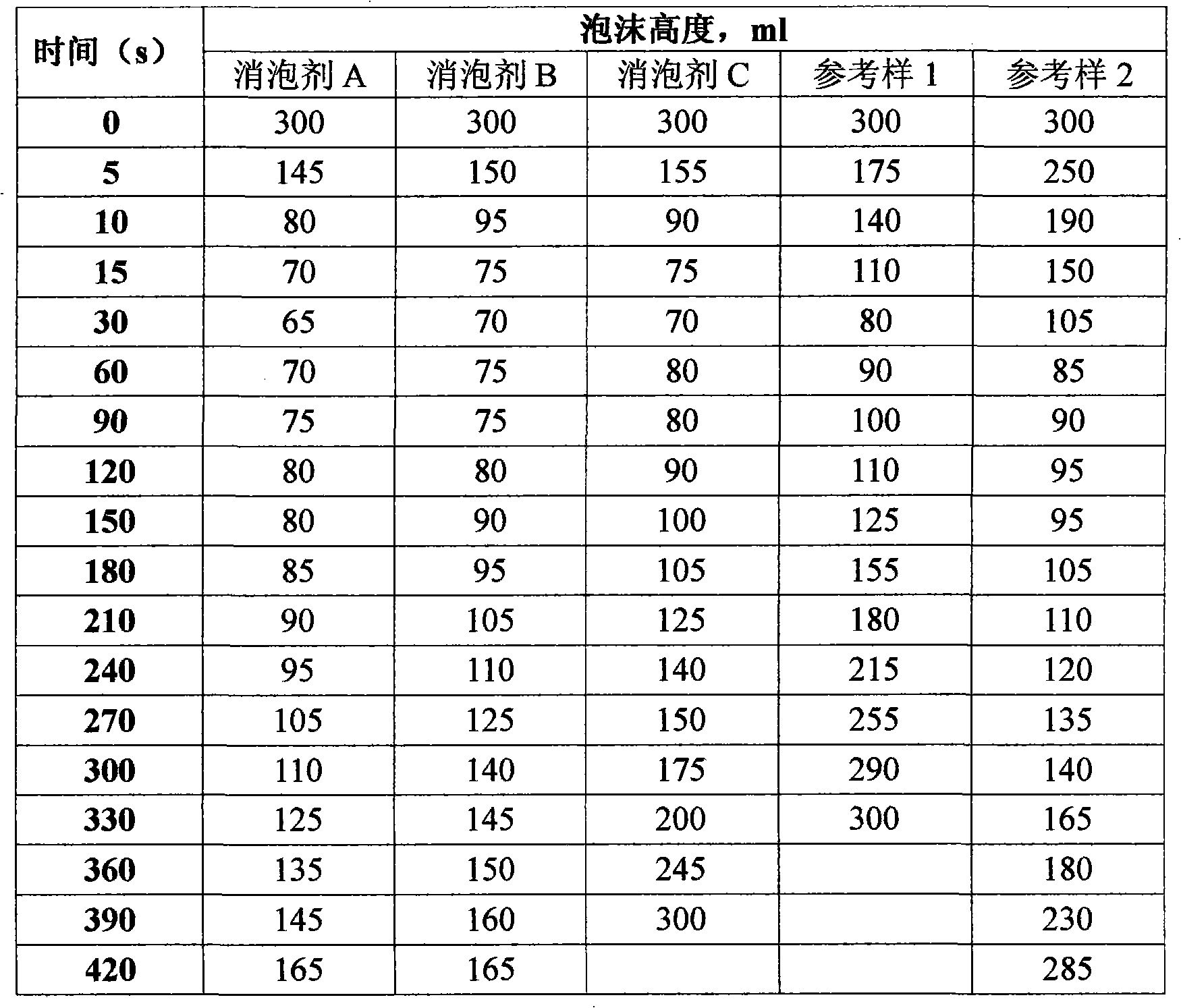

The invention relates to a preparation method of a novel papermaking wet part deformer, belonging to the field of special chemical preparations for papermaking. The novel papermaking wet part deformeris characterized by comprising the following components: 5-99 percent of fatty acid methyl ester derivative (1), 0.1-80 percent of polyether (2), 0.1-70 percent of modified polyether (3) and 0.1-20 percent of natural oil (4), wherein the fatty acid methyl ester derivative has a general structure formula of R<1>CO(EO)x(PO)yOCH3, a molecular weight of 300-3000 and a cloud point of 20-80 DEG C and is a product prepared by an addition reaction of ethylene oxide (EO) and propylene oxide (PO) under the action of a catalyst by using fatty acid methyl ester as an initiator; the polyether has a structural general formula of R<2>(M(EO)m(PO)nH)a, a molecular weight of 500-8,000 and a cloud point of 10-80 DEG C; and the modified polyether has a structural general formula of R<2>(M(EO)m(PO)nR<3>)a. The novel papermaking wet part deformer is not only suitable for a papermaking wet part working procedure, but also suitable for the treatment of papermaking waste water and the elimination of other water-phase foams.

Description

technical field [0001] The invention relates to the preparation of a novel paper-making wet-end defoamer. The defoamer is a fine chemical additive. Therefore, the preparation of a novel paper-making wet-end defoamer belongs to the field of special chemicals for papermaking. Background technique [0002] Papermaking is a key industry in the production of the national economy. In the paper industry, a variety of surfactants are often used, such as sizing agents, retention aids, filter aids, strengthening agents, deinking agents, dyes, etc. Active agents, they are also easy to foam during the operation of the paper machine. With the development of large industries, the speed of the paper machine is getting faster and faster. At present, the speed of the high-speed paper machine in production has reached 1800m / min. Paper whitening water is generally used in a closed cycle. During this process, if the air bubbles are not driven away in time, "pit" will be formed on the cardboard...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D21H21/12D21H17/53

CPCD21H21/12D21H23/04B01D19/0404D21H17/53

Inventor 吴飞曹治平孙颖欣郭佳曹添钟翔

Owner JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com