Defoaming agent for linerboard paper making

A technology of container board and defoamer, applied in the direction of defoamer, etc., can solve problems such as container board foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

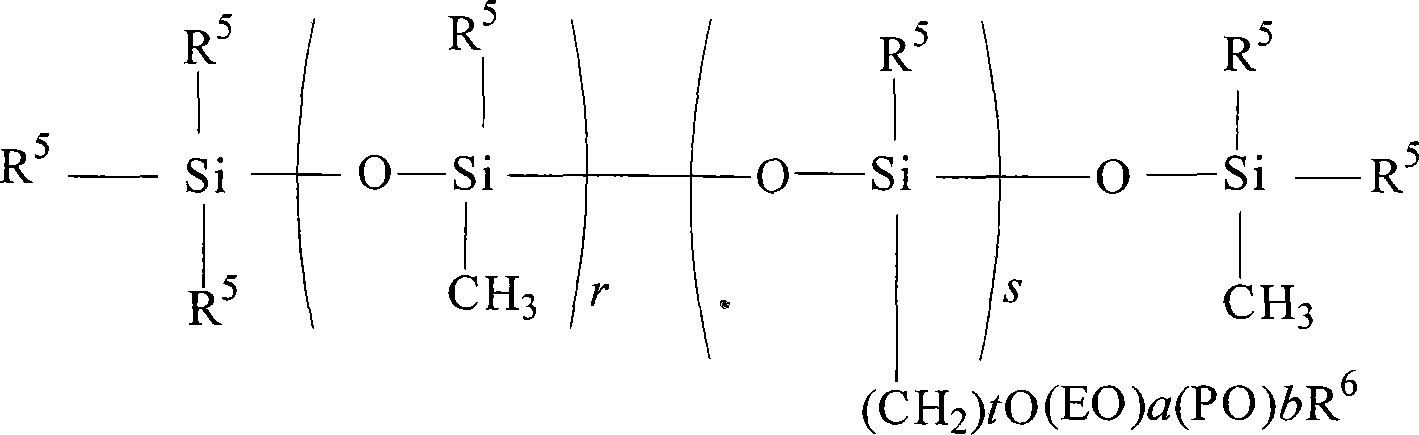

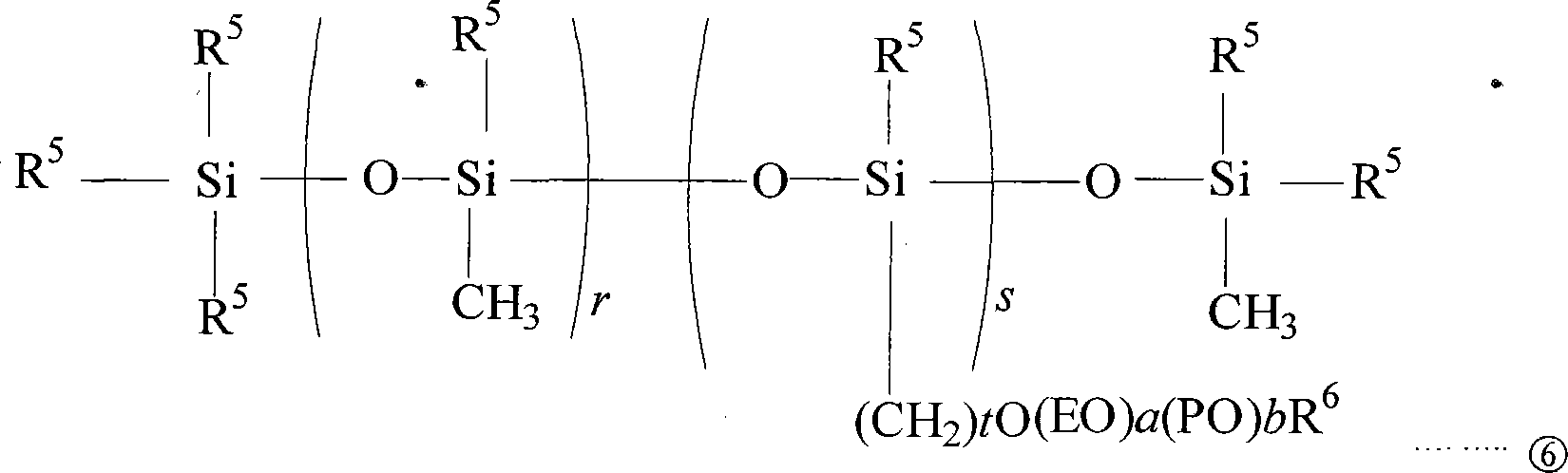

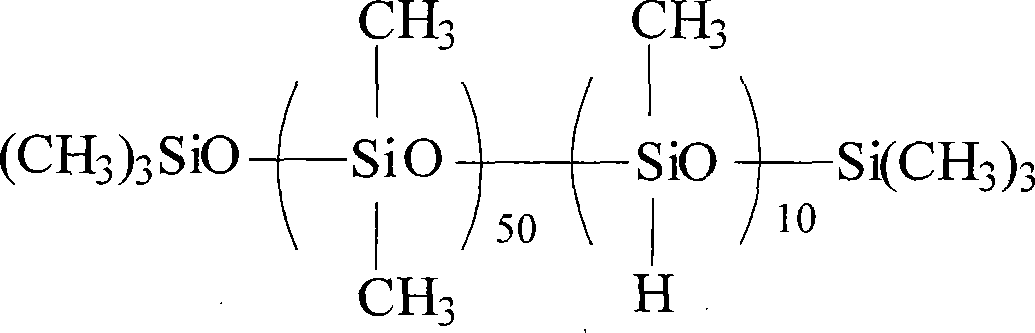

Method used

Image

Examples

example 1

[0065] Example 1: Preparation of organic hydrocarbon defoaming mixture O1:

[0066] Add 90 parts of liquid wax with a viscosity of 40 mPa·s and 4 parts of aluminum stearate into the reaction bottle, start stirring, and slowly raise the temperature. After the temperature rises to 135-140°C, keep it warm for 2 hours. Then add 6 parts of hydrophobic silica particles and mix evenly.

example 2

[0067] Example 2: Preparation of organic hydrocarbon defoaming mixture O2:

[0068] Add 93 parts of white oil with a viscosity of 5 mPa·s and 4 parts of EBS into the reaction flask, start stirring, and slowly raise the temperature. After the temperature rises to 135-140°C, keep it warm for 1 hour. Then add 3 parts of MQ resin (molar ratio M / Q=0.7:1) and mix evenly.

example 3

[0069] Example 3: Preparation of fatty alcohol polyether A1:

[0070] Add 130g of n-octanol and 100ppm of bimetallic catalyst to the polyether reactor, then vacuumize at 100°C to remove low molecular weight substances and trace moisture in the raw materials, and maintain it at a vacuum degree of -0.09~-0.1MPa 30min. Then continue to heat up to around 150° C., and add a mixture of ethylene oxide (EO) and propylene oxide (PO) to a total of 1000 g, wherein the mass of EO is 400 g, and the mass of PO is 600 g. After adding the mixed alkanes, keep it at the reaction temperature for 60 minutes, and finally cool down and discharge the material to obtain a colorless transparent viscous liquid, which is octanol polyether A1, and its average molecular weight is 1070.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Cloud point | aaaaa | aaaaa |

| Cloud point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com