Anti-foaming agent for papermaking system

A defoamer and system technology, applied in the direction of defoamer, papermaking, textiles and papermaking, etc., can solve problems such as process influence and product instability, and achieve the effect of eliminating harmful foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

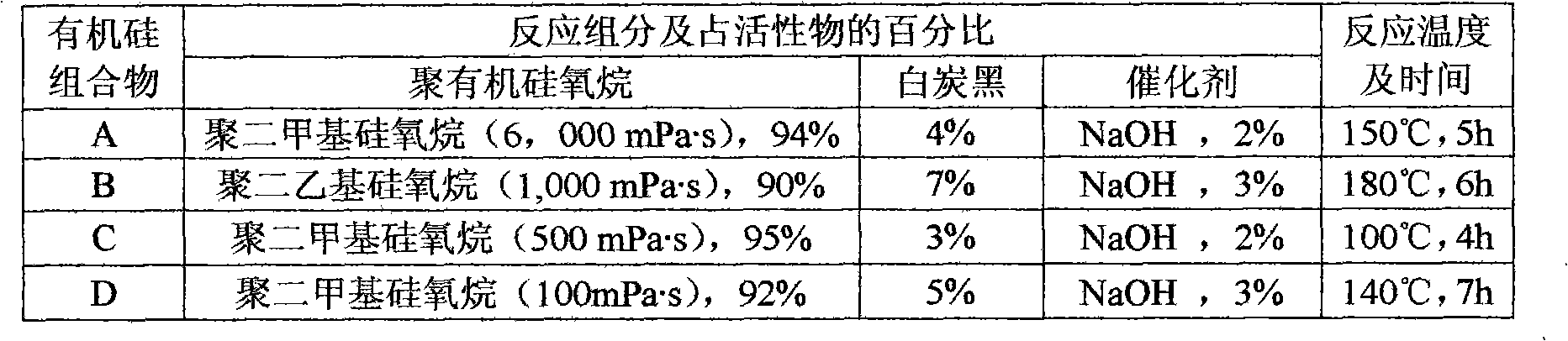

[0029] Preparation of Silicone Composition:

[0030] The organosilicon composition was prepared by using the above-mentioned preparation process of the organosilicon composition and the conditions in the following table.

[0031] Table 1 Silicone composition

[0032]

Embodiment 1

[0034] Add 5 parts of octadecyl alcohol, 2 parts of glycerol monostearate, 5 parts of higher fatty alcohol polyethers (structural formula is C 13 h 27 O(EO) 5 (PO) 7 H), 2 parts of silicone composition A, 2 parts of N-90 (polyether modified polysiloxane, made by Nanjing Sixin Technology Application Research Institute Co., Ltd.) and 1 part of P-70 (polyether modified polysiloxane Oxane, made by Nanjing Sixin Technology Application Research Institute Co., Ltd.), the system was heated to 80 ° C, stirred for a while, so that the components were mixed evenly; then slowly added 70 parts of water to it, and after the water was added, it was ground and dispersed by a colloid mill. Until the particle size of the emulsion is less than 15 μm, the defoamer E is obtained.

Embodiment 2

[0036] Add 5 parts of lauryl alcohols, 5 parts of higher fatty alcohol polyethers (structural formula is C 18 h 37 O(PO) 10 H), 4 parts of octyl stearate, 6 parts of silicone composition B, 2 parts of nonylphenol polyoxyethylene ether (10) and 2 parts of nonylphenol polyoxyethylene ether (3), the temperature of the system was raised to 70°C , keep warm for 10 minutes, slowly add 70 parts of water, after adding water, grind and disperse by colloid mill to make the particle size of the emulsion less than 15 μm, and obtain defoamer F.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com