Process for producing printed decorative raw paper by using recycled waste paper

A production process and decorative base paper technology, applied in the direction of paper recycling, waste paper processing, recycling technology, etc., to achieve the effect of solving recycling problems, reducing waste water discharge, reducing raw material consumption and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

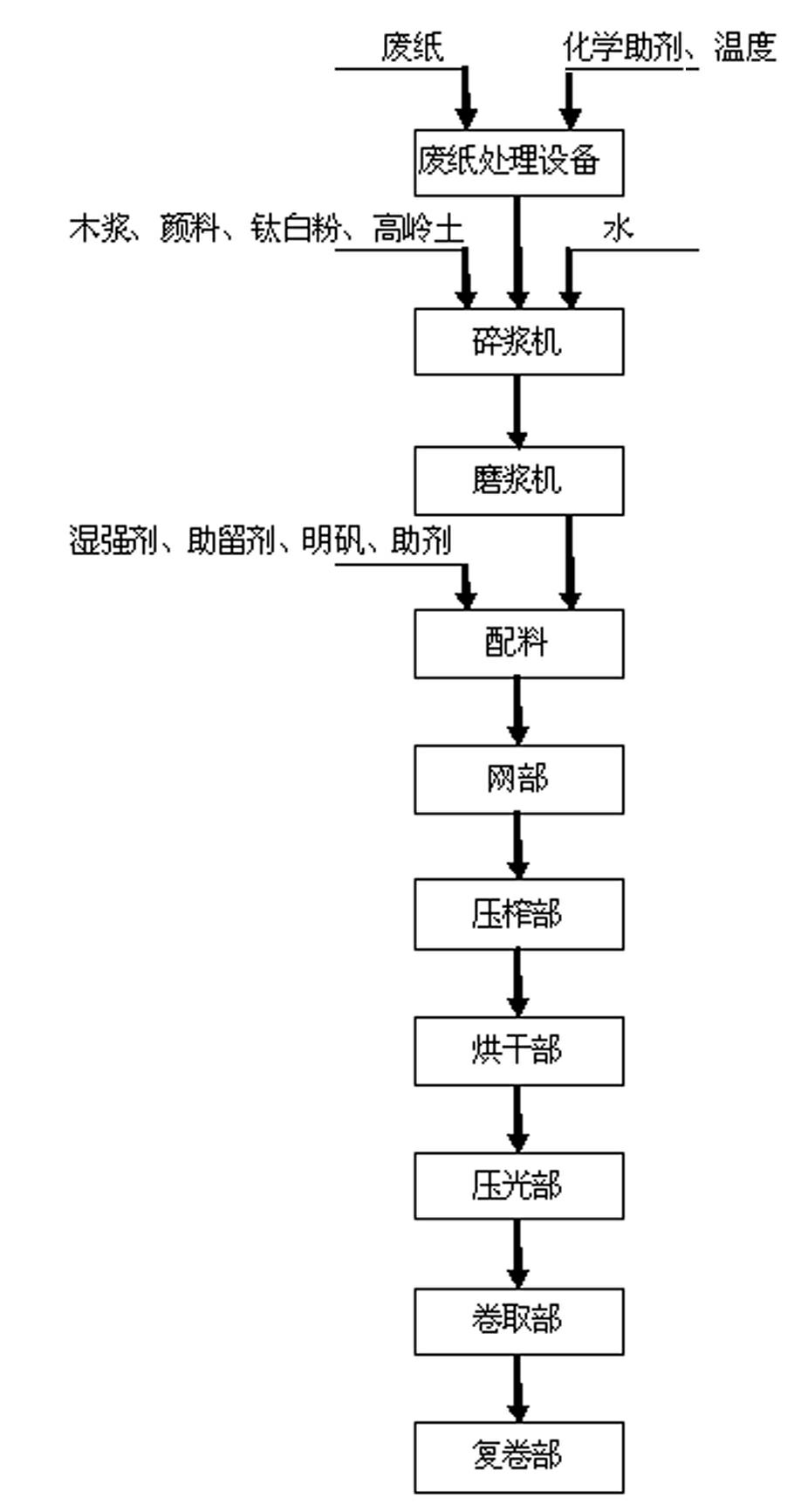

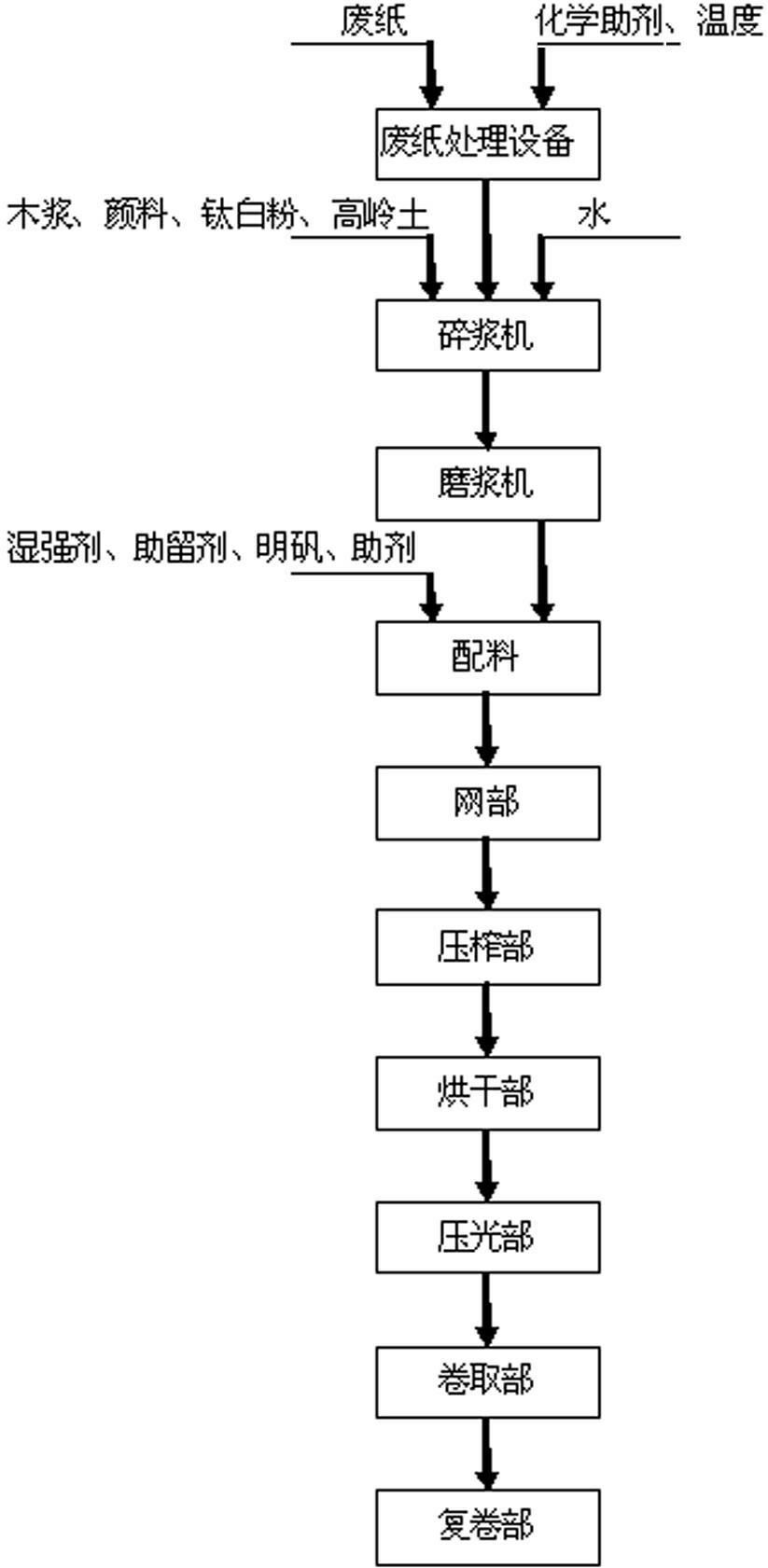

[0017] refer to figure 1 , the production process steps of waste paper recovery type printing decoration base paper of the present invention are as follows:

[0018] The first step: waste paper treatment, put 85% waste paper and 15% chemical additives into the waste paper treatment equipment and mix them, and remove the waste paper at a temperature of 45°C with the help of chemical additives Tape, ink and other impurities in the waste paper and water are prepared with a pH value of 8.5 and a mass percentage concentration of 7.0%. The waste paper is completely decomposed into a waste paper slurry without paper pieces and free ink. The chemical additives include sodium hypochlorite And sodium hydroxide, the weight ratio of sodium hypochlorite and sodium hydroxide is 1:3;

[0019] The second step: pulping, through the pulping equipment, the waste paper pulp, wood pulp, titanium dioxide, pigment and water after the above treatment are mixed evenly, and the slurry with a mass perc...

Embodiment 2

[0024] refer to figure 1 , the production process steps of waste paper recovery type printing decoration base paper of the present invention are as follows:

[0025] The first step: waste paper treatment, put 88% waste paper and 12% chemical additives into the waste paper treatment equipment and mix them, and remove the waste paper at a temperature of 48°C with the help of chemical additives Tape, ink and other impurities in the waste paper and water are prepared with a pH value of 9.0 and a mass percentage concentration of 7.5%. The waste paper is completely decomposed into a waste paper slurry without paper pieces and free ink. The chemical additives include sodium hypochlorite. And sodium hydroxide, the weight ratio of sodium hypochlorite and sodium hydroxide is 1:3;

[0026] The second step: pulping, through the pulping equipment, the waste paper pulp, wood pulp, titanium dioxide, pigment and water after the above treatment are mixed evenly, and the slurry with a mass per...

Embodiment 3

[0031] refer to figure 1 , the production process steps of waste paper recovery type printing decoration base paper of the present invention are as follows:

[0032] The first step: waste paper treatment, put 80% waste paper and 20% chemical additives into the waste paper treatment equipment and mix them, and remove the waste paper at a temperature of 42°C through the assistance of chemical additives Tape, ink and other impurities in the waste paper and water are prepared with a pH value of 8.7 and a mass percentage concentration of 6.5%. The waste paper is completely decomposed into a waste paper slurry without paper pieces and free ink. The chemical additives include sodium hypochlorite. And sodium hydroxide, the weight ratio of sodium hypochlorite and sodium hydroxide is 1:3;

[0033] The second step: pulping, through the pulping equipment, the waste paper pulp, wood pulp, titanium dioxide, pigment and water after the above treatment are mixed evenly, and the slurry with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com