Electrostatic prevention temperature-resistant marking material and manufacturing method thereof

An anti-static and marking technology, applied in the direction of chemical instruments and methods, film/sheet adhesives, applications, etc., can solve problems that restrict the development of the electronic assembly manufacturing industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

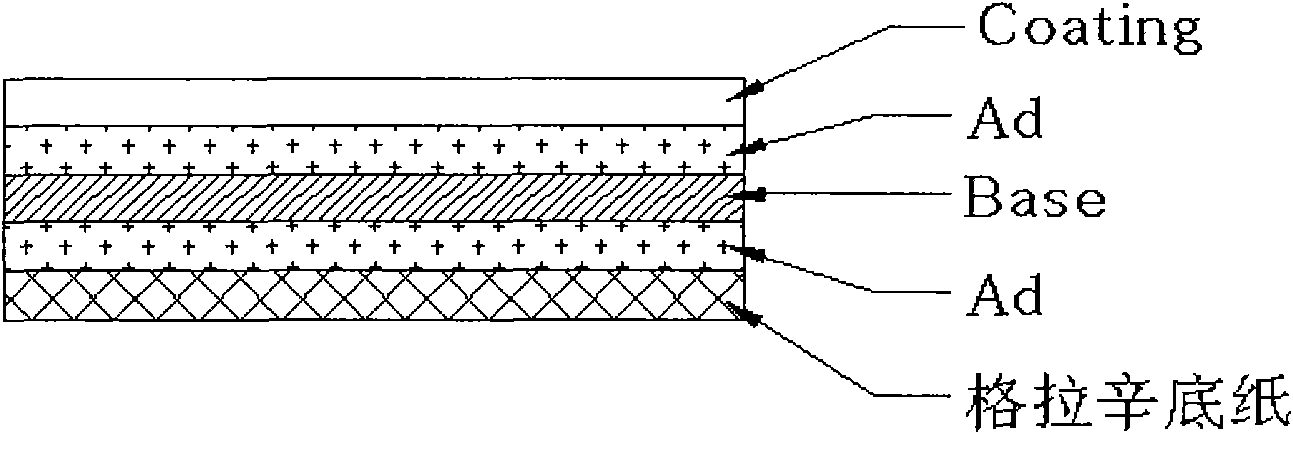

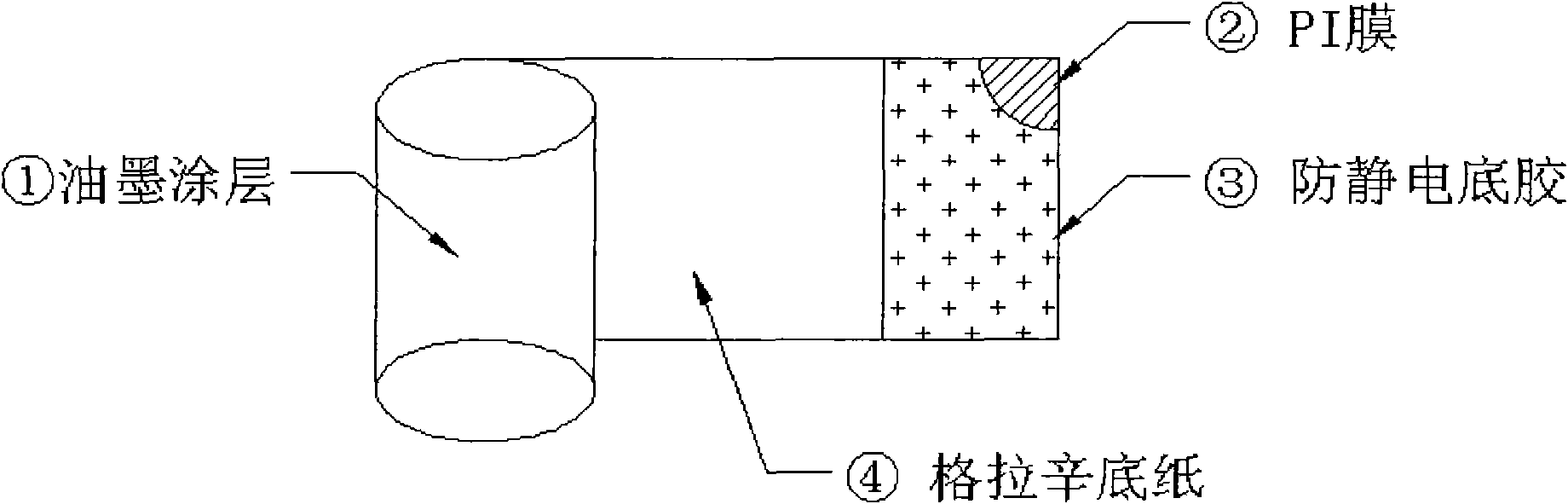

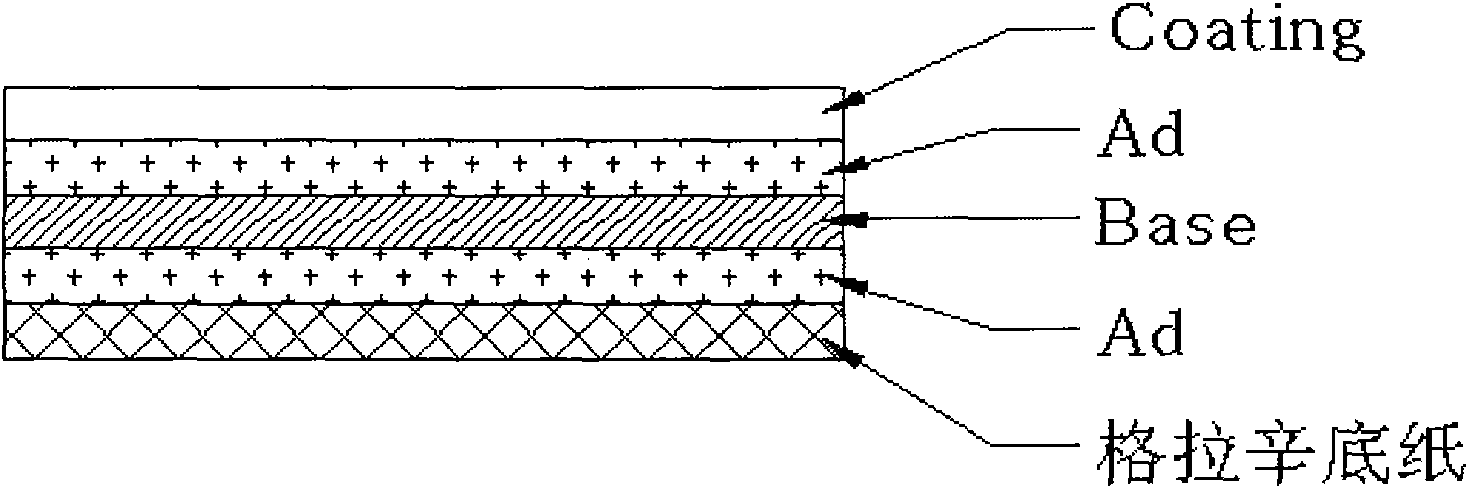

[0015] A) Select a flawless polyimide material with a thickness of 25um and no pinholes and the like with static electricity dissipation as the substrate 2, unwind it and pass it through the rotating rubber wheel of the model FQS-60 corona elimination static electricity equipment , adjust the corresponding current and voltage, and then start the machine for double-sided corona treatment, so that it is easy to combine with the ink coating 1, the substrate 2, and the antistatic pressure-sensitive adhesive 3 to improve the bonding force between them.

[0016] B) First put the mixed modified resin paint into the squeegee tank of the coater, and adjust the gap between the scraper and the coating roller to 20um, then turn on the heating button of the coater, and put the coater The temperature of zone 1 (substrate 2 entry zone), zone 2 (middle zone) and zone 3 (substrate 2 exit zone) of the oven is controlled at 90°C, 140°C, and 90°C respectively, and then the transmission button of t...

Embodiment example 2

[0019] A) Select a flawless polyimide material with a thickness of 30um and no pinholes and the like with static electricity dissipation as the substrate 2, unwind it and pass it through the rotating rubber wheel of the model FQS-60 corona elimination static electricity equipment , adjust the corresponding current and voltage, and then start the machine for double-sided corona treatment, so that it is easy to combine with the ink coating 1, the substrate 2, and the antistatic pressure-sensitive adhesive 3 to improve the bonding force between them.

[0020] B) First put the mixed modified resin paint into the squeegee tank of the coater, and adjust the gap between the scraper and the coating roller to 20um, then turn on the heating button of the coater, and put the coater The temperature of zone 1 (substrate 2 entry zone), zone 2 (middle zone) and zone 3 (substrate 2 exit zone) of the oven is controlled at 90°C, 140°C, and 90°C respectively, and then the transmission button of t...

Embodiment example 3

[0023] A) Select a flawless polyimide material with a thickness of 50um and no pinholes and the like with static electricity dissipation as the substrate 2, unwind it and pass it through the rotating rubber wheel of the model FQS-60 corona elimination static electricity equipment , adjust the corresponding current and voltage, and then start the machine for double-sided corona treatment, so that it is easy to combine with the ink coating 1, the substrate 2, and the antistatic pressure-sensitive adhesive 3 to improve the bonding force between them.

[0024] B) First put the mixed modified resin paint into the squeegee tank of the coater, and adjust the gap between the scraper and the coating roller to 20um, then turn on the heating button of the coater, and put the coater The temperature of zone 1 (substrate 2 entry zone), zone 2 (middle zone) and zone 3 (substrate 2 exit zone) of the oven is controlled at 90°C, 140°C, and 90°C respectively, and then the transmission button of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com