Reverse flotation collecting agent of cellophane and preparation method thereof

A collector and reverse flotation technology, used in flotation, solid separation and other directions, can solve the problems of lack of market competitiveness, increased dosage of chemicals, and reduced dispersibility, so as to promote sustainable development and reduce the dosage of chemicals. Less and less cost effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] According to the molar ratio of α-chlorooleic acid: sodium hydroxide = 1:2 ingredients, add α-chlorooleic acid to an aqueous solution of 10wt% sodium hydroxide and mix, control the reaction temperature to 110°C, react for 2 hours, and cool To obtain sodium α-hydroxy oleate, add sulfuric acid solution to the obtained sodium α-hydroxy oleate to acidify until the pH value is neutral, stir mechanically for 2 hours, wash with hot water, and separate layers to obtain α-hydroxy oleic acid. Take 1 kg of α-hydroxy oleic acid, 0.2 kg of sodium hydroxide (formed as a 16.67% aqueous solution), and 1 kg of lauric acid in a reactor at a temperature of 60° C., and mechanically stir for 2 hours to obtain the basic substance. Add water to make it into an aqueous solution with a solid content of 2wt%, which is the reverse collector.

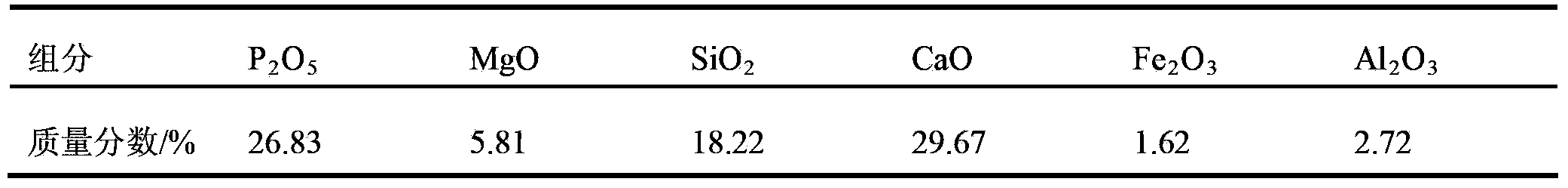

[0024] Taking a high-magnesium refractory collophosite in Yichang as an ore sample, the chemical composition of the raw ore is:

[0025]

[0026] Use t...

Embodiment 2

[0031] According to the molar ratio of α-chlorooleic acid: sodium hydroxide = 1:2.5 ingredients, add α-chlorooleic acid to the aqueous solution of 35wt% sodium hydroxide and mix, control the reaction temperature to 150 ° C, react for 3 hours, and cool To obtain sodium α-hydroxy oleate, add the obtained sodium α-hydroxy oleate to sulfuric acid solution to acidify until the pH value becomes neutral, stir mechanically for 3 hours, wash with hot water, and separate by layers to obtain α-hydroxy oleic acid. Take 2.5kg of α-hydroxyoleic acid, 0.5kg of sodium hydroxide (33.33% aqueous solution), 0.1kg of oleic acid, and 1kg of palmitic acid in a reactor at a temperature of 75°C and mechanically stir for 3 hours to obtain the basic substance. Adding water to make it 2wt% aqueous solution is the reverse collector.

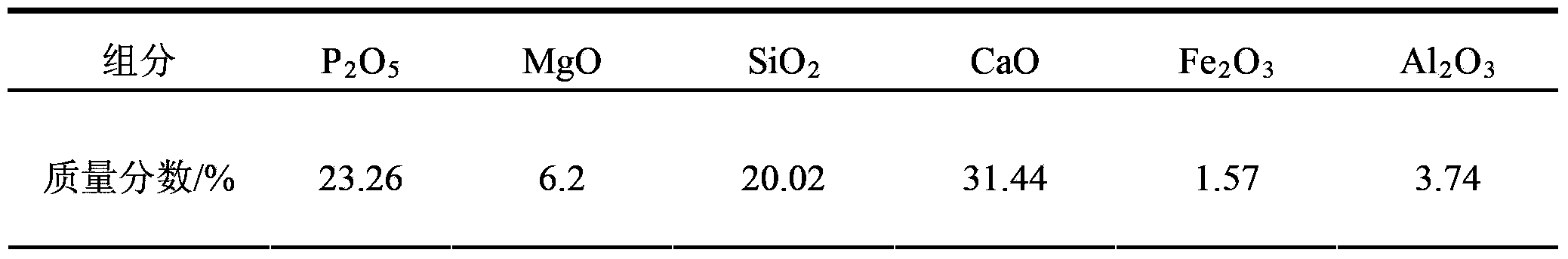

[0032] Taking middle and low-grade high-calcium-magnesium carbonate-type collophanite in Haikou, Yunnan Province as the ore sample, the chemical composition of the raw ore ...

Embodiment 3

[0039] According to the molar ratio of α-chlorooleic acid: sodium hydroxide = 1:5 ingredients, add α-chlorooleic acid to an aqueous solution of 75wt% sodium hydroxide and mix, control the reaction temperature to 160 ° C, react for 5 hours, and cool To obtain sodium α-hydroxy oleate, add sulfuric acid solution to the obtained sodium α-hydroxy oleate to acidify until the pH value is neutral, stir mechanically for 5 hours, wash with hot water, and separate layers to obtain α-hydroxy oleic acid. Take 5 kg of α-hydroxy oleic acid, 1.5 kg of potassium hydroxide (33.33% aqueous solution), 1 kg of oleic acid, and 1 kg of stearic acid in a reactor at a temperature of 95° C. and mechanically stir for 5 hours to obtain the basic substance. Adding water to make it 2wt% aqueous solution is the reverse collector.

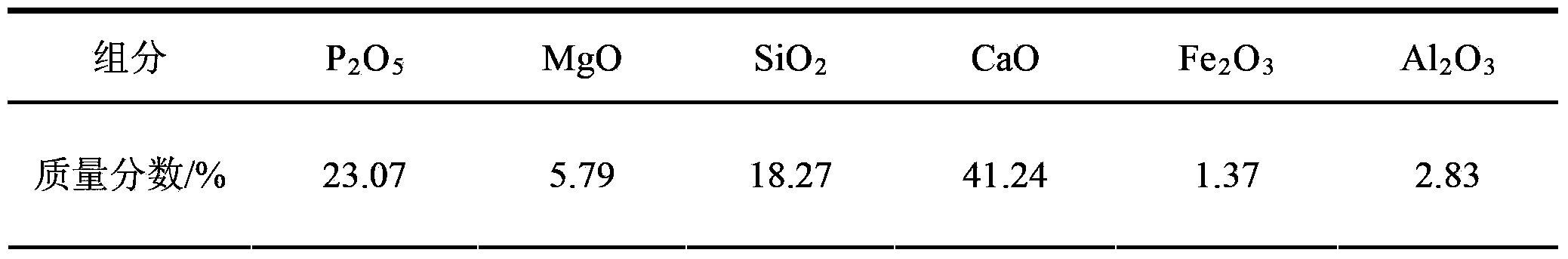

[0040] Taking Mabian high-magnesium collophosite in Sichuan as the ore sample, the chemical composition of the raw ore is:

[0041]

[0042] Use this collector to carry out s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com