Superhydrophobic coating preparation method, coating prepared therethrough, and application of coating in production of highly-transparent superhydrophobic coating layer

A super-hydrophobic coating and coating technology, applied in the coating and other directions, can solve the problems of harsh experimental conditions, difficult mass production, complicated operation process, etc., and achieve the effects of low cost, strong adhesion and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Add 60 mL of isopropanol, 6 mL of deionized water, and 6 mL of ammonia water into a clean three-neck flask, control the magnetic stirring speed at 120 rad / min to 180 rad / min, and stir at room temperature for 5 min.

[0033] (2) Add 0.2mL tetraethyl orthosilicate and 0.02mL of 3,3,4,4,5,5,6,6,7,7,8,8,9,9, 10,10,10-heptadecafluorodecyltrimethoxysilane, stirred for 24 hours, and the stirring speed was controlled at 180rad / min~240rad / min.

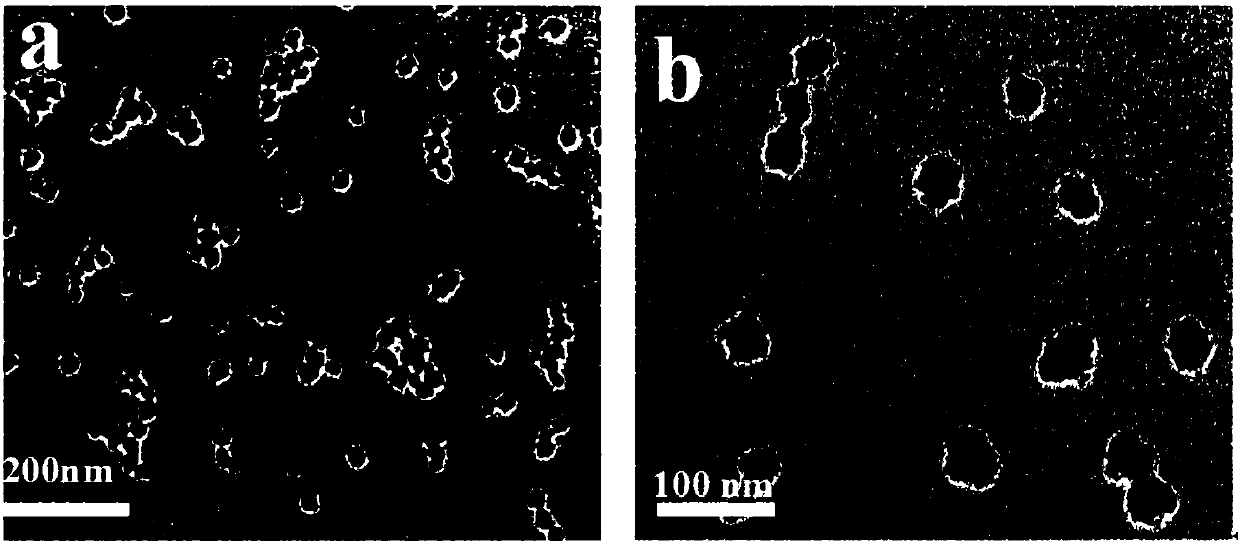

[0034] (3) After the reaction (2) is finished, take the suspension of (2) and spray or dip it on a clean glass sheet, and dry it in vacuum at 60°C for 5 minutes to obtain a transparent superhydrophobic coating. figure 1 It is the TEM image of the nanoparticle suspension obtained in (2), it can be seen that the particle diameters are all less than 100nm, and most of them are below 60nm.

Embodiment 2

[0036] (1) Add 80 mL of ethanol, 4 mL of deionized water, and 4 mL of hydrochloric acid into a clean three-neck flask, control the magnetic stirring speed at 120 rad / min to 180 rad / min, and stir at room temperature for 5 min.

[0037] (2) Add 1 mL of tetraethyl orthosilicate and 0.05 mL of 1H,1H,2H,2H-perfluoroheptadecanetrimethyloxysilane to (1) in turn, stir for 24 hours, and control the stirring speed at 180 rad / min~240rad / min.

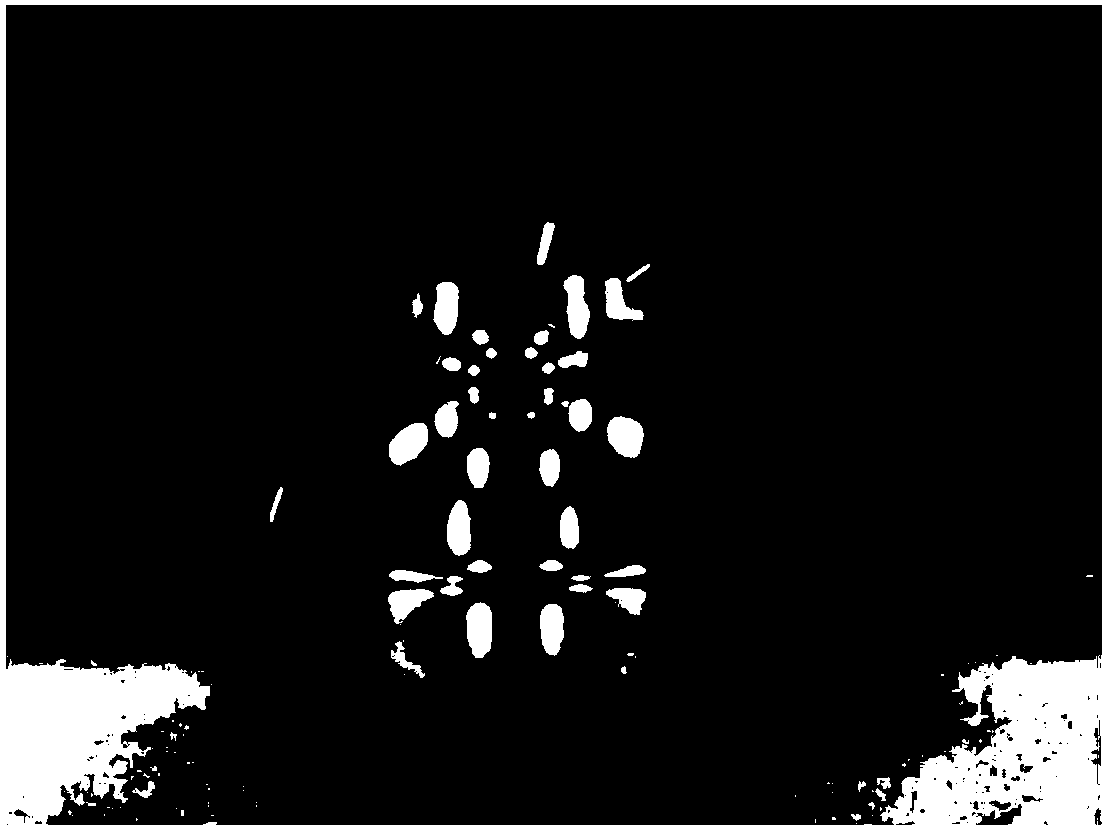

[0038] (3) After the reaction (2), take the suspension of (2) and spray or dip it on a clean glass sheet, and dry it in vacuum at 60°C for 5 minutes to obtain a transparent superhydrophobic coating. figure 2 is the contact angle of a water droplet on the transparent superhydrophobic coating, which is 163°.

Embodiment 3

[0040] (1) Add 100 mL of methanol, 2 mL of deionized water, and 2 mL of sodium hydroxide into a clean three-neck flask, control the magnetic stirring speed at 120 rad / min to 180 rad / min, and stir at room temperature for 5 min.

[0041] (2) Add 0.5mL ethyl silicate and 0.03mL 1H,1H,2H,2H-perfluoroheptadecanetrimethyloxysilane to (1) sequentially, stir for 24 hours, and control the stirring speed at 180rad / min ~240rad / min.

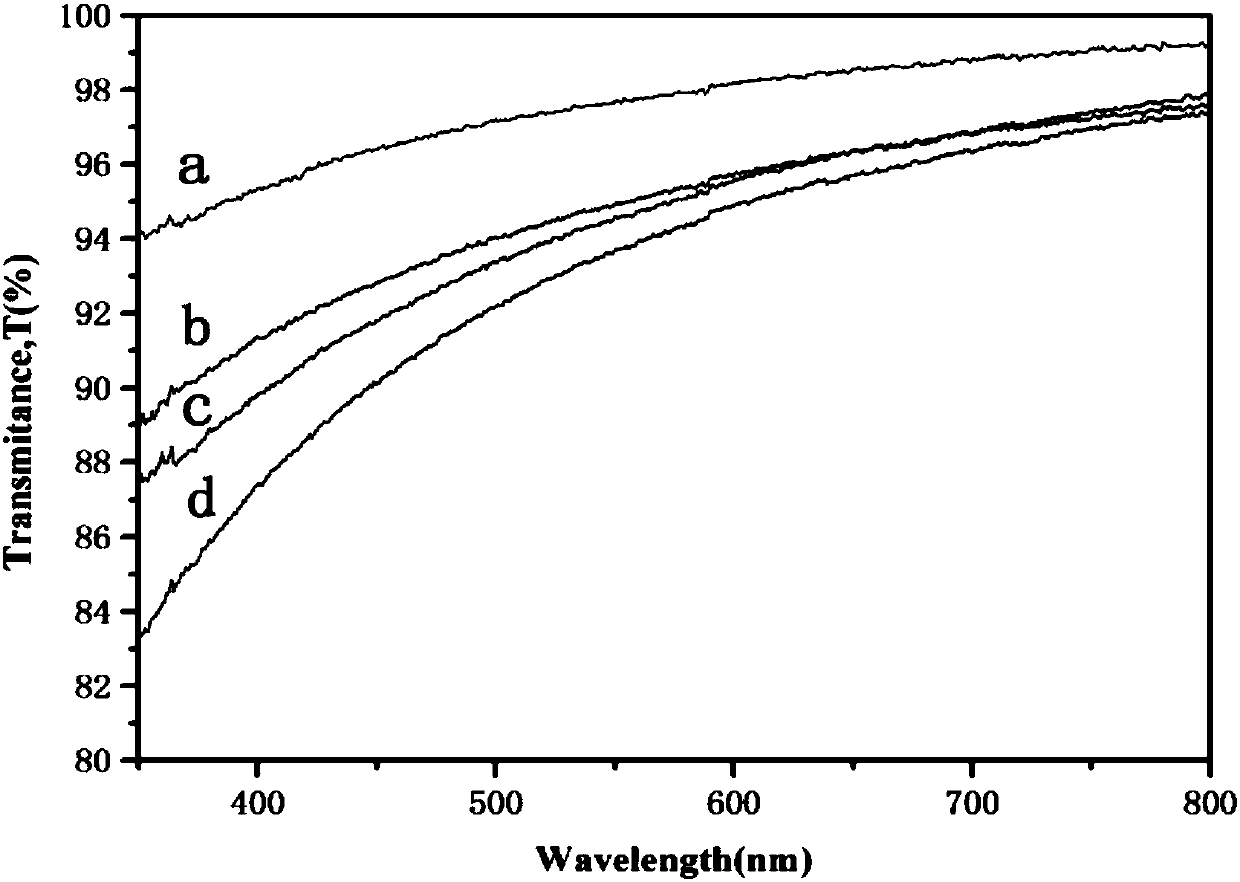

[0042] (3) After the reaction (2), take the suspension of (2) and spray or dip it on a clean glass sheet, and dry it in vacuum at 60°C for 5 minutes to obtain a transparent superhydrophobic coating. image 3 UV-visible light analysis diagrams of glass coated with different water content (a pure glass; b water content 2mL; c 0mL; d 4mL), compared with pure glass, the visible light transmittance of b and c are above 90%, The visible light transmittance of d is also over 87%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com