Process and device thereof for sticking magnetic steel on rotor of high-power permanent magnet motor for vehicles

A permanent magnet motor, high-power technology, used in the manufacture of stator/rotor bodies, etc., to achieve the effects of easy manufacture, improved efficiency and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

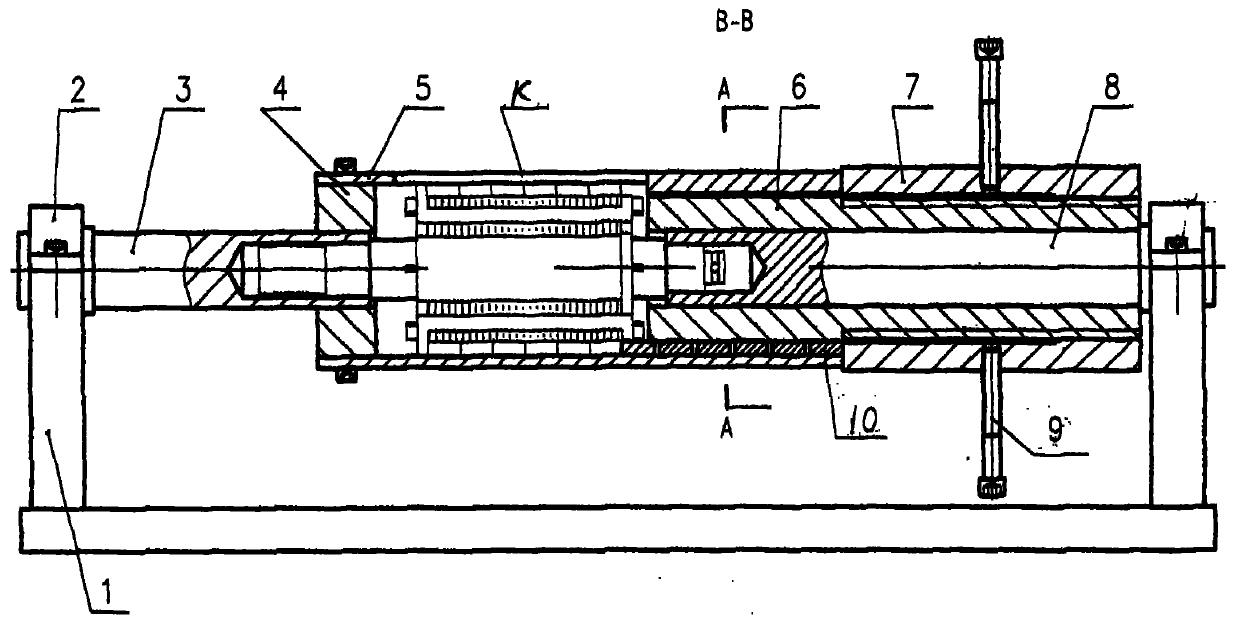

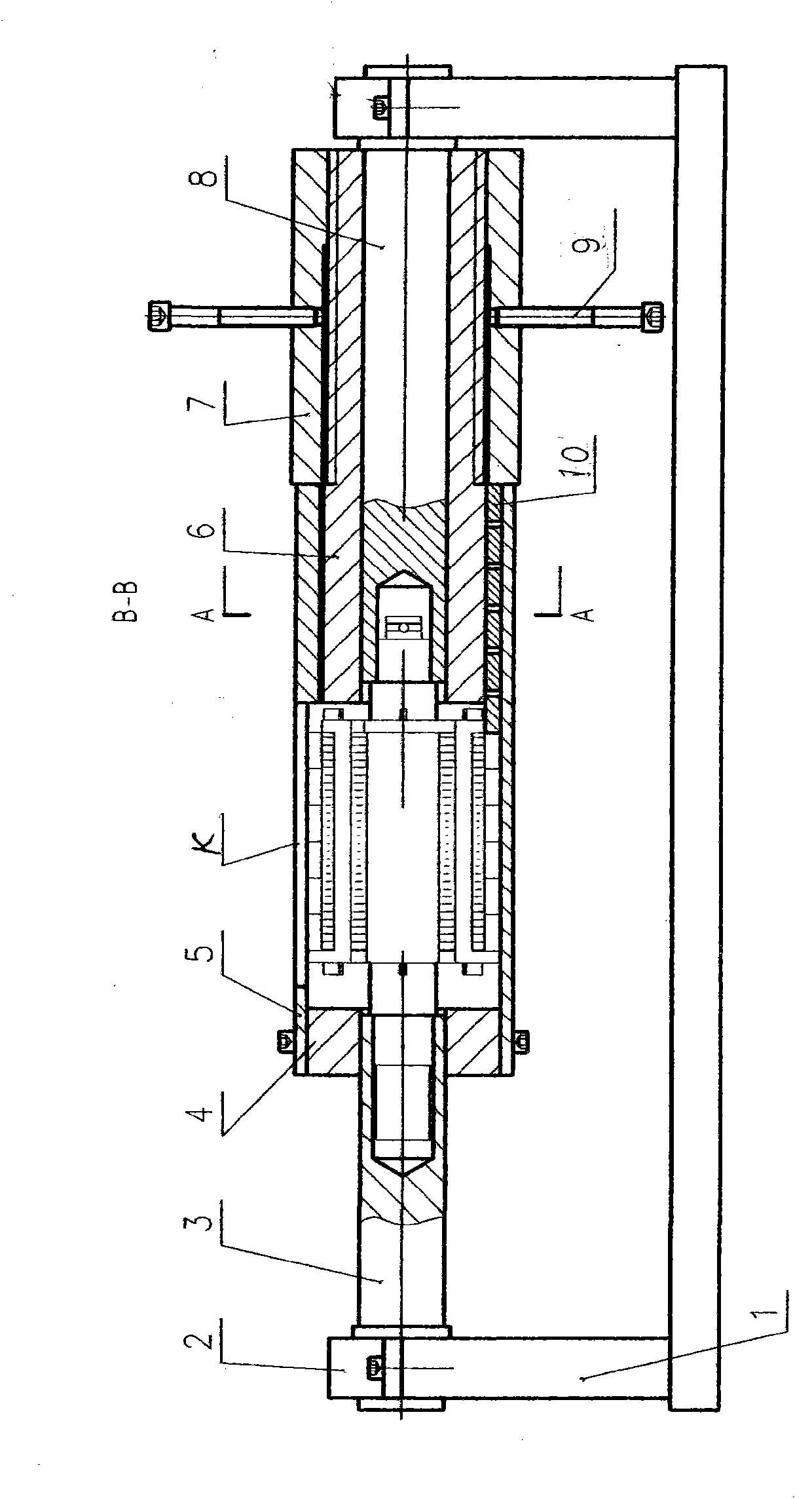

[0022] The present invention relates to the drive power of electric buses and electric cars—a special process device for pasting the rotor magnets of high-power permanent magnet motors for vehicles and a process flow of the pasting process for the rotor magnets of permanent magnet motors.

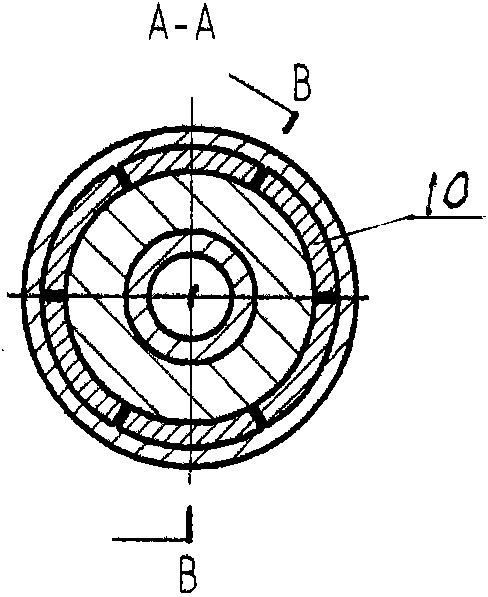

[0023] The inner hole of the mold cover 5 is slidingly matched with the outer circle of the motor rotor magnetic pole. On the outer circle of one end of the mold cover 5, a window K parallel to the axial center line is made along the direction of the axis line. The length of the window is longer than the length of the motor rotor magnetic pole. Auxiliary guide support block 4 is installed on the end of the inner hole at this end, and fixed by screws, and six partitions are evenly distributed in the inner hole of the other end according to the circumference, so that the partitions are arranged in the axial direction, and the inner hole is separated. Six axial positioning grooves are formed, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com