Intelligent wall tile attaching robot

A robot and ceramic tile technology, applied in construction, building construction, etc., can solve problems such as insufficient space and inability to realize equipment, and achieve the effect of stable work, improved paste quality, and liberation of manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

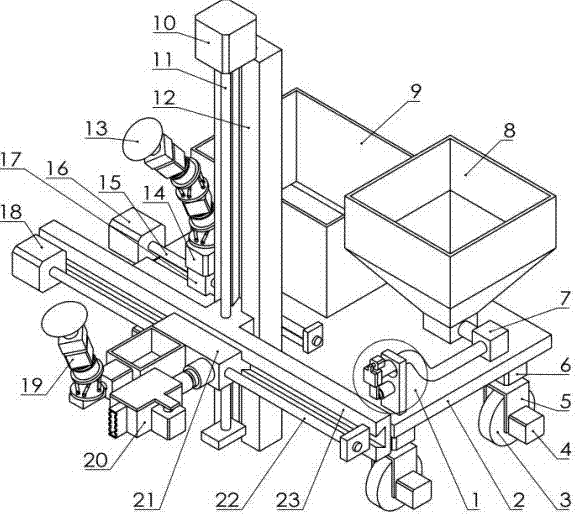

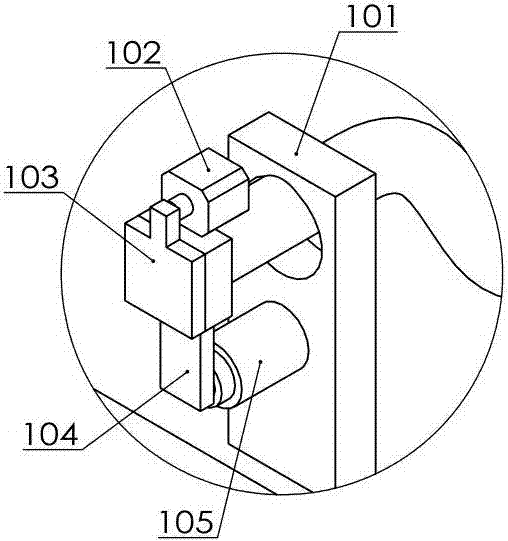

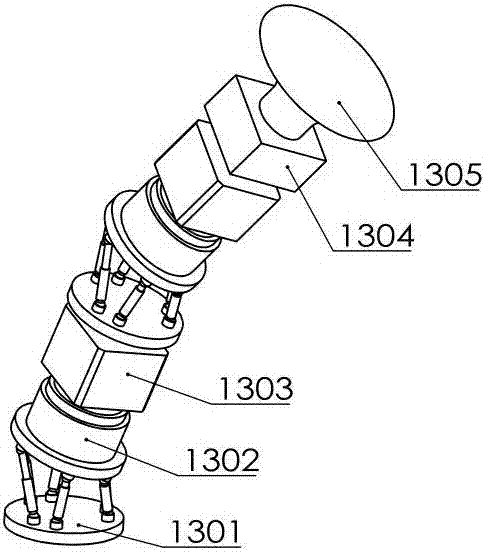

[0029] Such as figure 1 , figure 2 , image 3, Figure 4 , Figure 5 , Figure 6 A wall tile intelligent pasting robot shown includes a pipe head assembly 1, a bottom plate 2, four wheels 3, four first stepping motors 4, four wheel frames 5, four first servo motors 6, cement Pump 7, cement storage box 8, tile storage box 9, second servo motor 10, first lead screw 11, vertical guide rail 12, fixed tile grabbing arm 13, second stepping motor 14, second lead screw 15, the first Three servo motors 16, the first sliding seat 17, the fourth servo motor 18, the moving tile box assembly 19, the cement wiper 20, the second sliding seat 21, the third screw 22, and the horizontal guide rail 23, are characterized in that:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com