Caulking device and caulking method for building facing bricks

A decorative brick and construction technology, applied in the direction of architecture, building structure, etc., can solve the problems that affect the quality of appearance and decorative effect, the adhesion of free calcium oxide cannot be removed, and the pollution and whitening of decorative bricks, etc., so as to improve the decorative effect and improve the adhesion. Quality, enhance the effect of anti-leakage ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

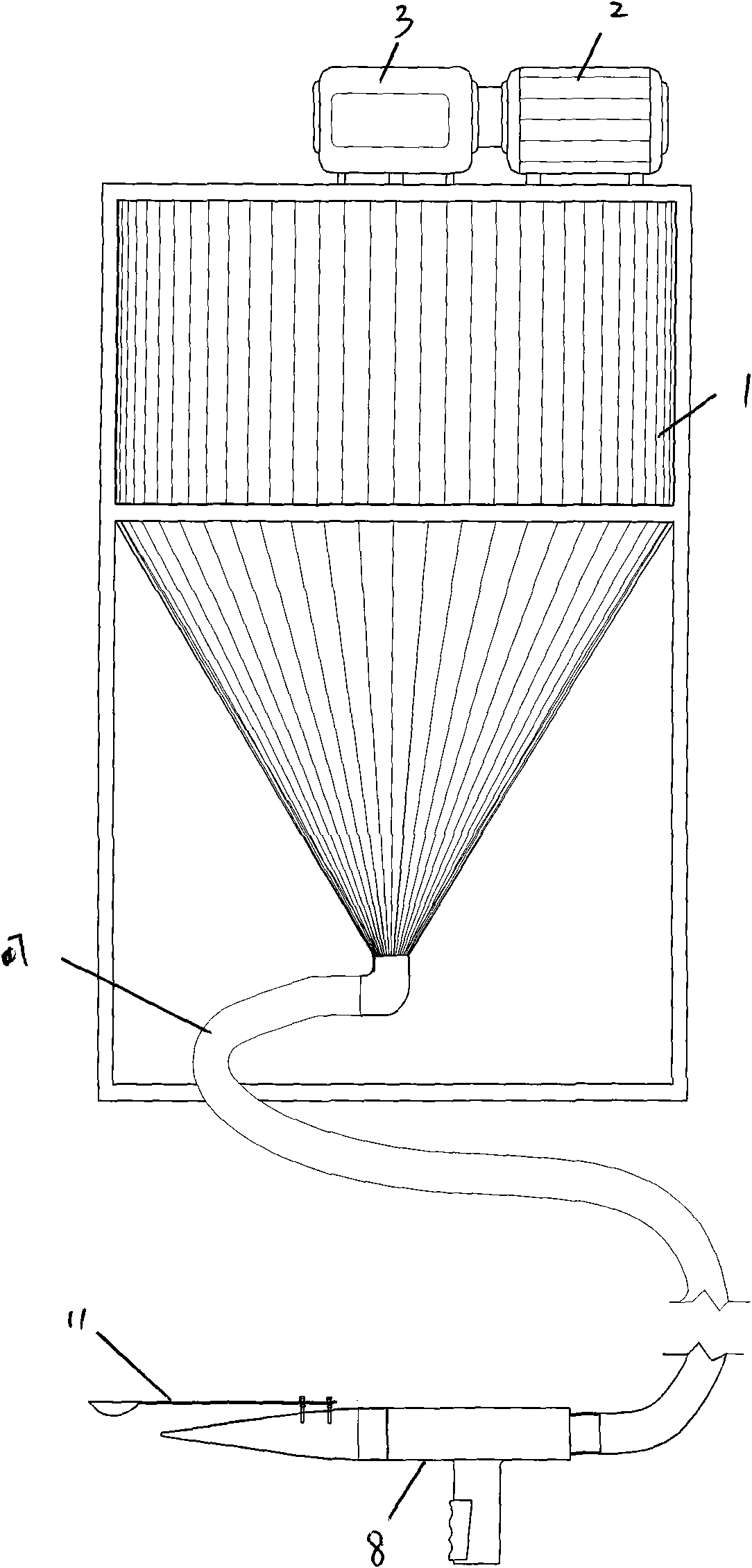

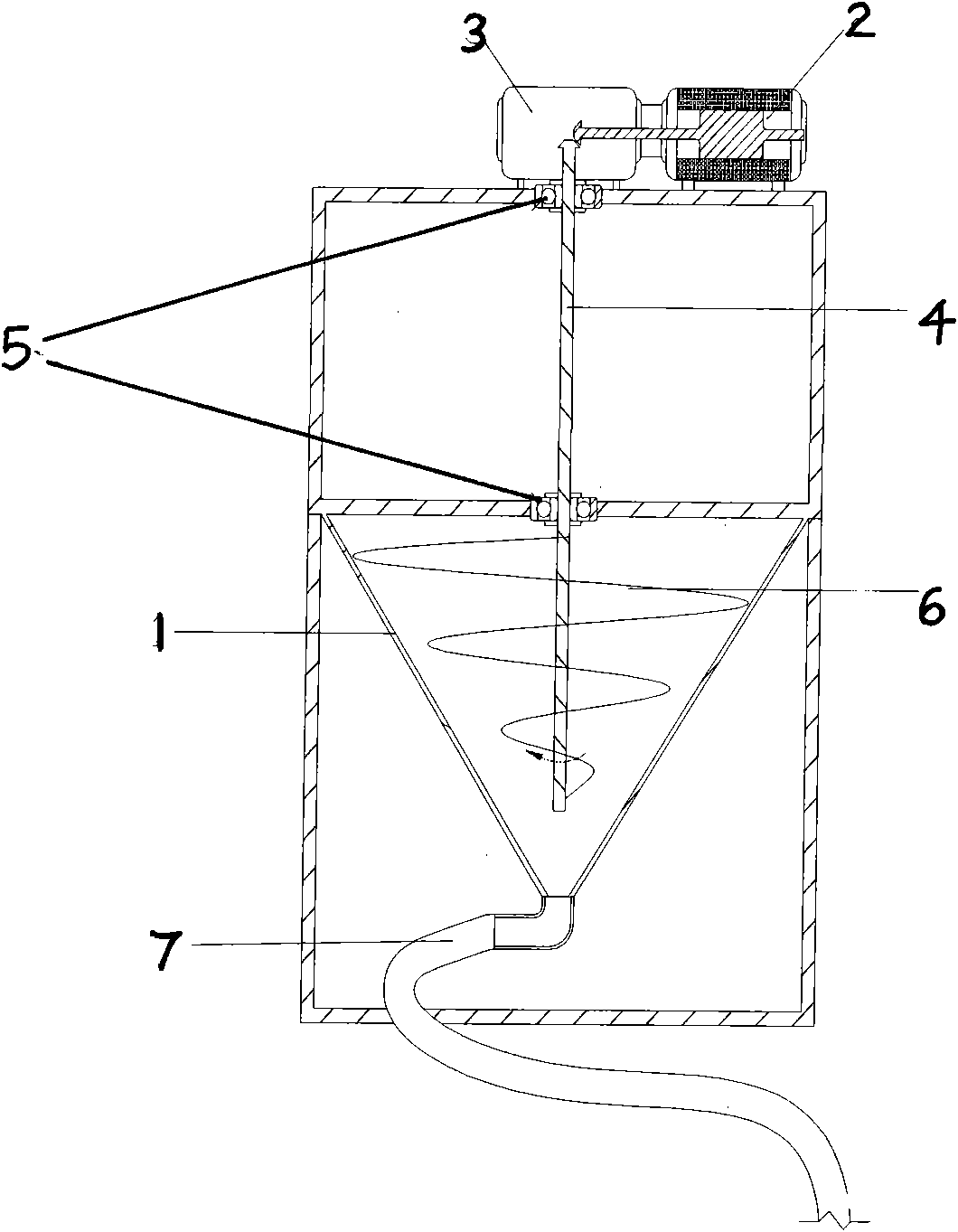

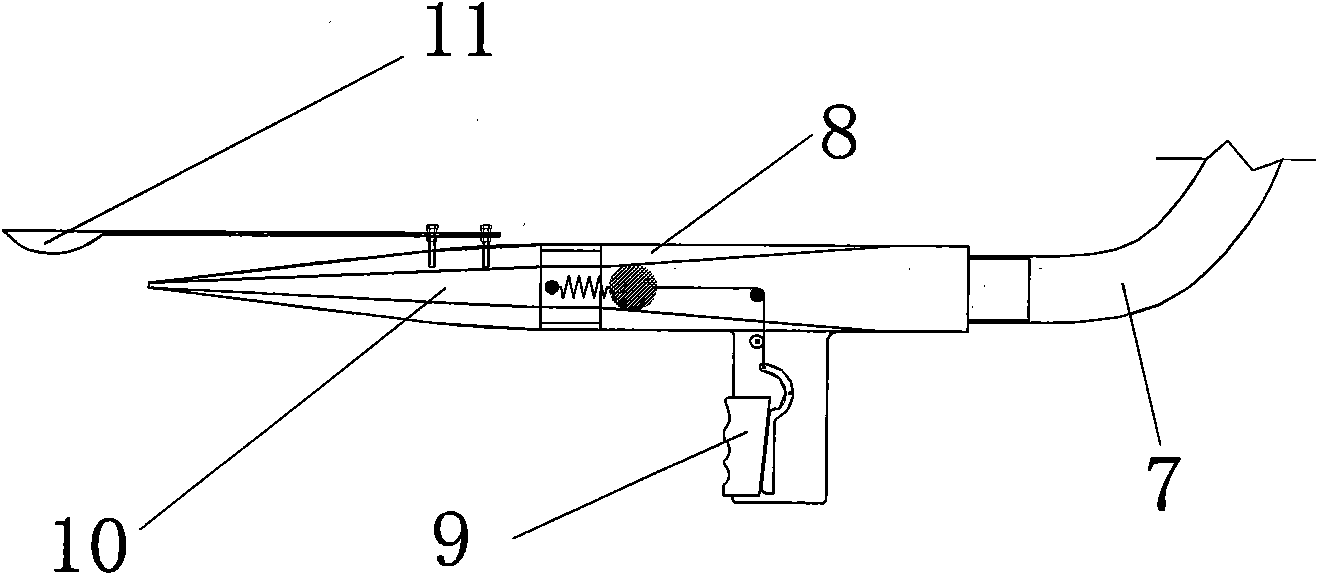

[0022] see Figure 1-3 , the building facing brick caulking device provided by the invention is composed of a mortar stirring device Figure 1-2 , transfer hose 7 and caulking device image 3 Composition: The mortar stirring and conveying device is composed of a funnel-shaped metal barrel 1, a motor 2, a reducer 3, a vertical shaft 4, a bearing seat 5, a spiral blade 6, and a conveying hose 7. Caulking device image 3 It consists of a caulking nozzle assembly 8, a hand switch 9, a stainless steel caulking nozzle 10 and a stainless steel grouting reed 11.

[0023] The motor 2 and the reducer 3 are installed on the top of the metal barrel 1 to drive the vertical shaft 4 to rotate. The bearing seat 5 supports and controls the vertical shaft 4. The spiral blade 6 below rotates to stir the brick slurry downward. The mortar passes through the transmission hose 7 to the caulking nozzle assembly. Squeeze into 8, and once the hand-held switch 9 is turned on, the mortar will be squee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com