Strain gauge automatic welding and pasting device

A sticking device and automatic welding technology, applied in the direction of connection, connecting components, material gluing, etc., can solve the problems of difficult to control the sticking position, waste of strain gauges, delaying time, etc., to achieve automatic sticking, improve sticking quality, and save sticking time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

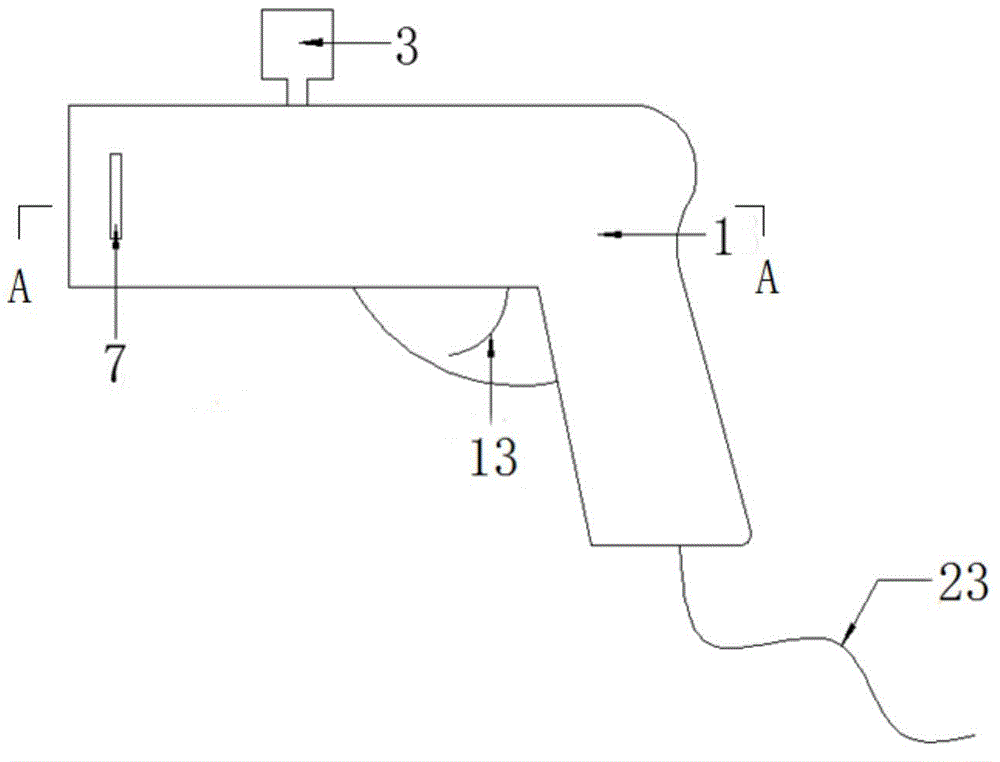

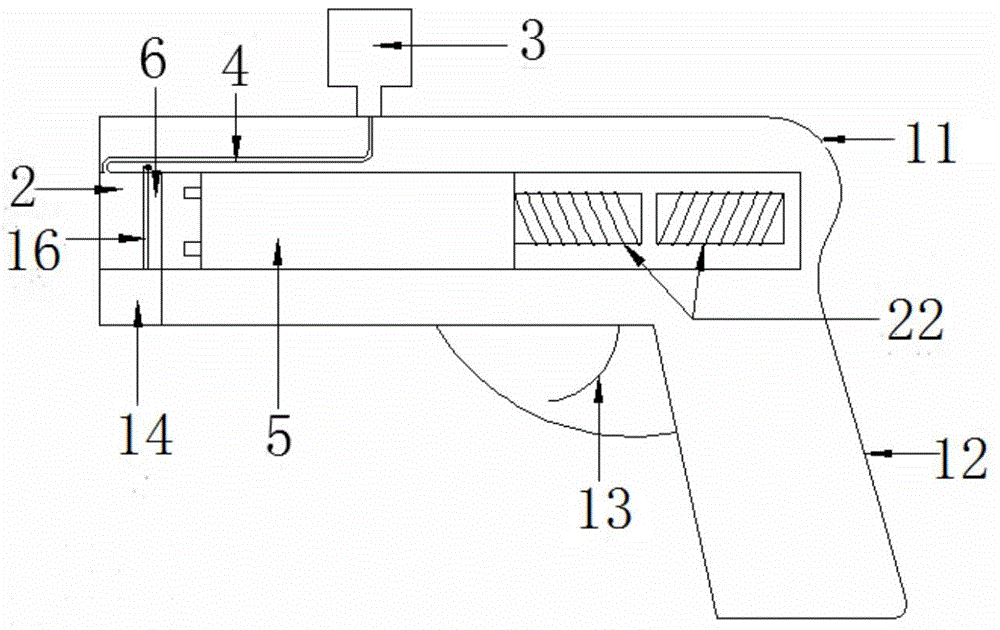

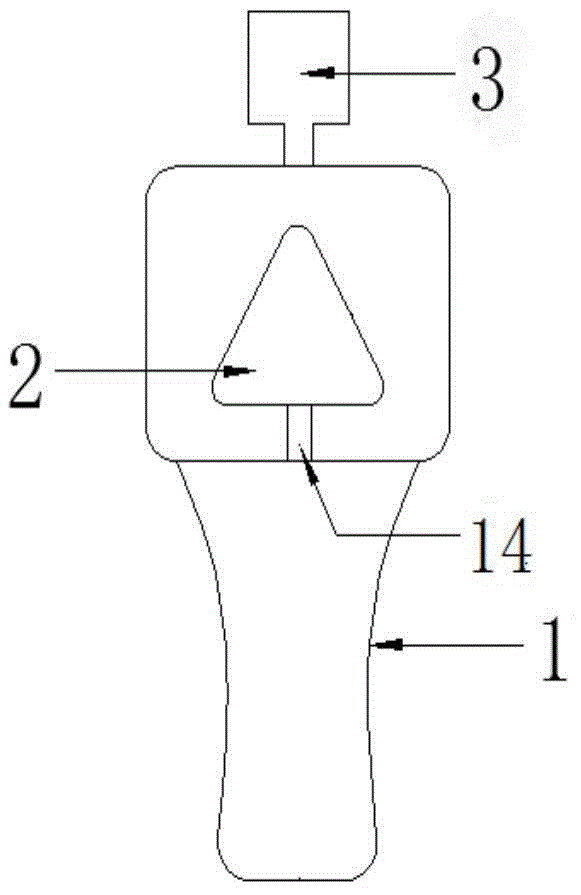

[0016] Such as figure 1 , figure 2 , image 3 As shown, the strain gauge automatic welding and pasting device includes: a gun-shaped main body 1; the gun-shaped main body 1 includes a gun barrel 11, a handle 12 is provided under the rear end of the gun barrel, and a trigger 13 is provided at the intersection of the top of the front side of the handle 12 and the gun barrel ; The gun barrel 11 is provided with a smoothbore 2, the smoothbore 2 extends from the gun barrel front end to the rear end but does not penetrate the rear end, and the cross section of the smoothbore 2 is a triangle; Rod 5, carrier 6, curled welding baffle 16; a carrier hole 7 is provided on one side of the front end of the gun barrel 11, and the carrier hole 7 vertically runs through the smooth bore 2, and the bottom of the gun barrel 11 extends backward from the front end with a wiring chute 14, the bottom wall through which the wiring chute 14 penetrates.

[0017] Such as figure 2 , Figure 4 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com