Flange-type magnetic steel pasting machine

A sticking machine and flange-type technology, which is applied in electromechanical devices, manufacturing motor generators, manufacturing stator/rotor bodies, etc., can solve problems such as uneven force, uneven glue coating, and different spacing between magnetic steels. , to achieve the effect of controllable speed and force, consistent height and spacing, and improved paste quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

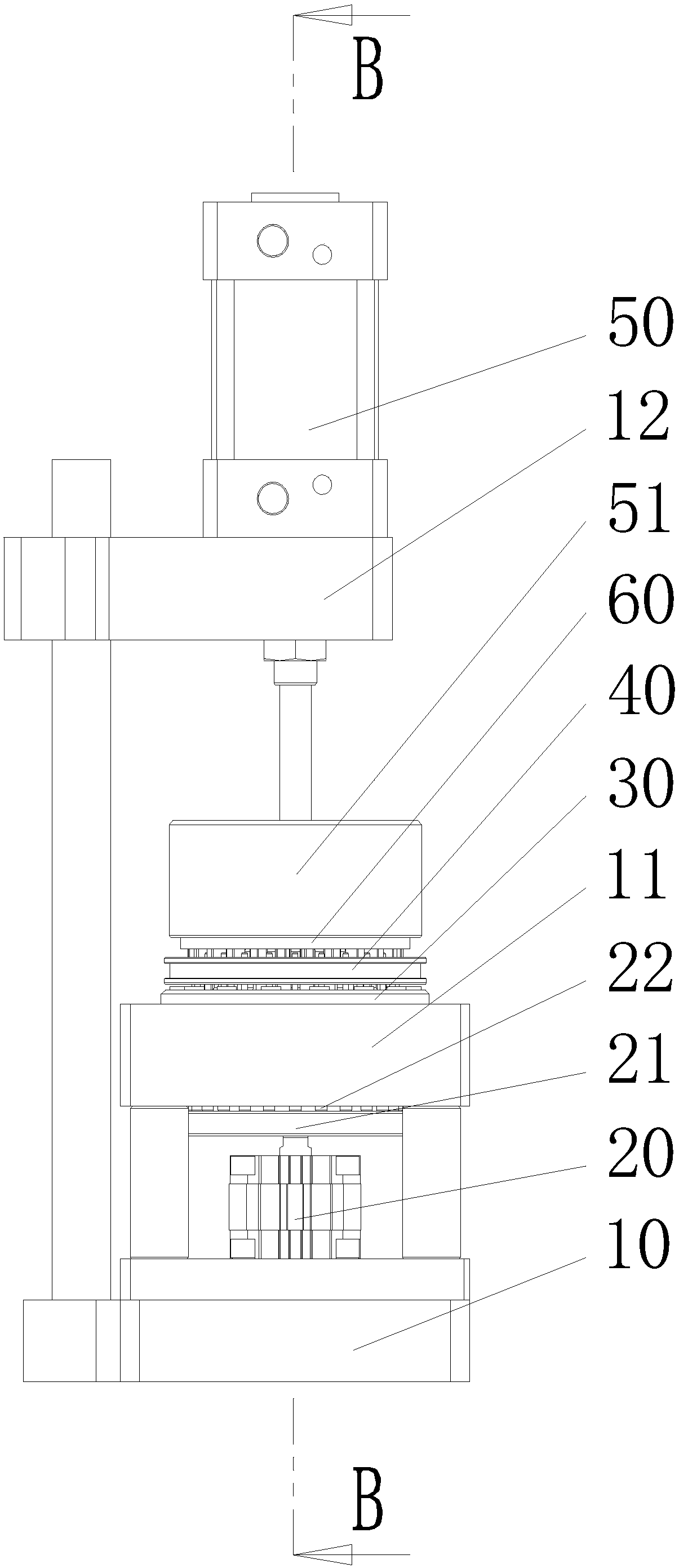

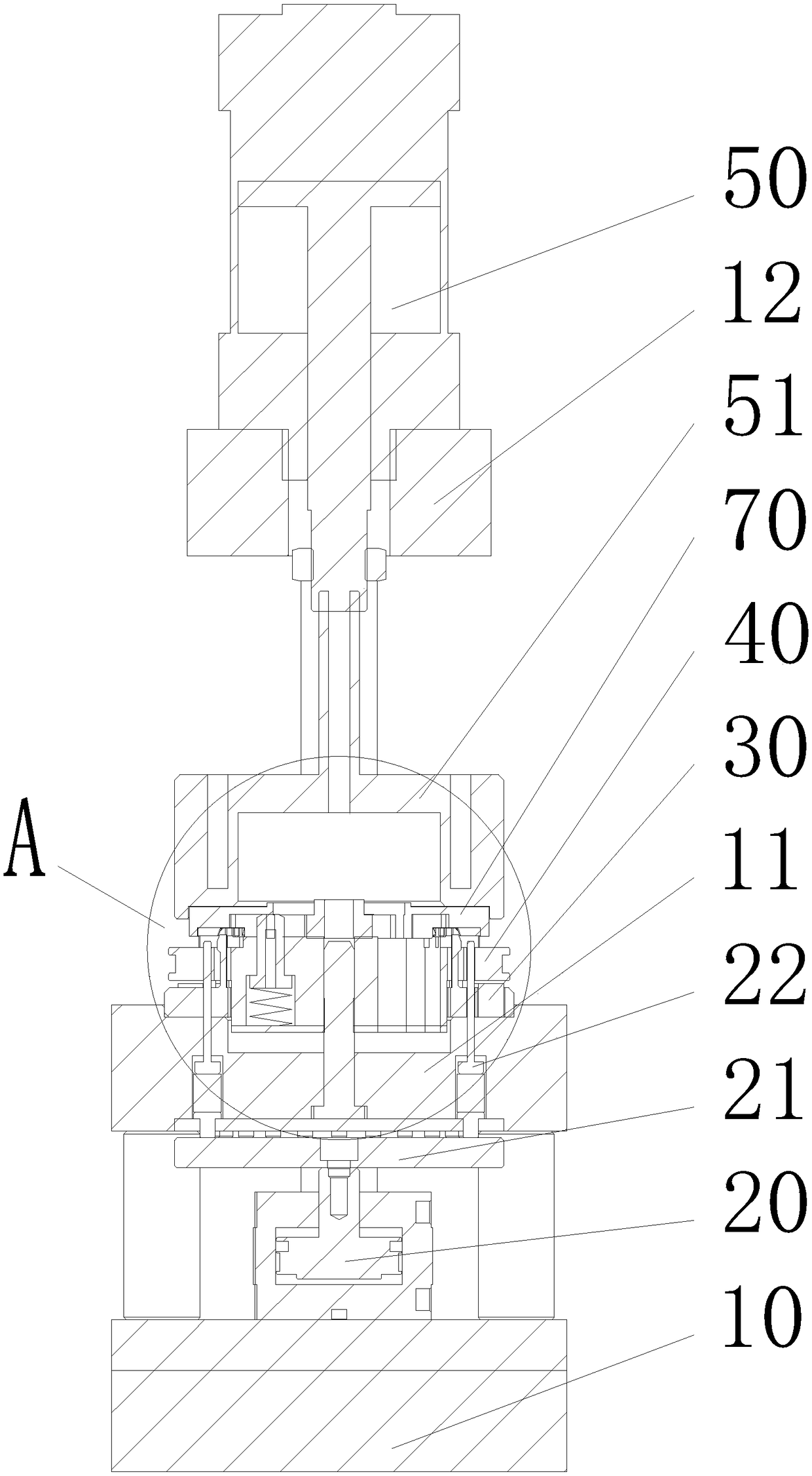

[0024] refer to Figure 1 to Figure 5 As shown, the present invention discloses a flange-type magnetic steel pasting machine, which includes a frame 10 , a lower bracket 11 and an upper bracket 12 .

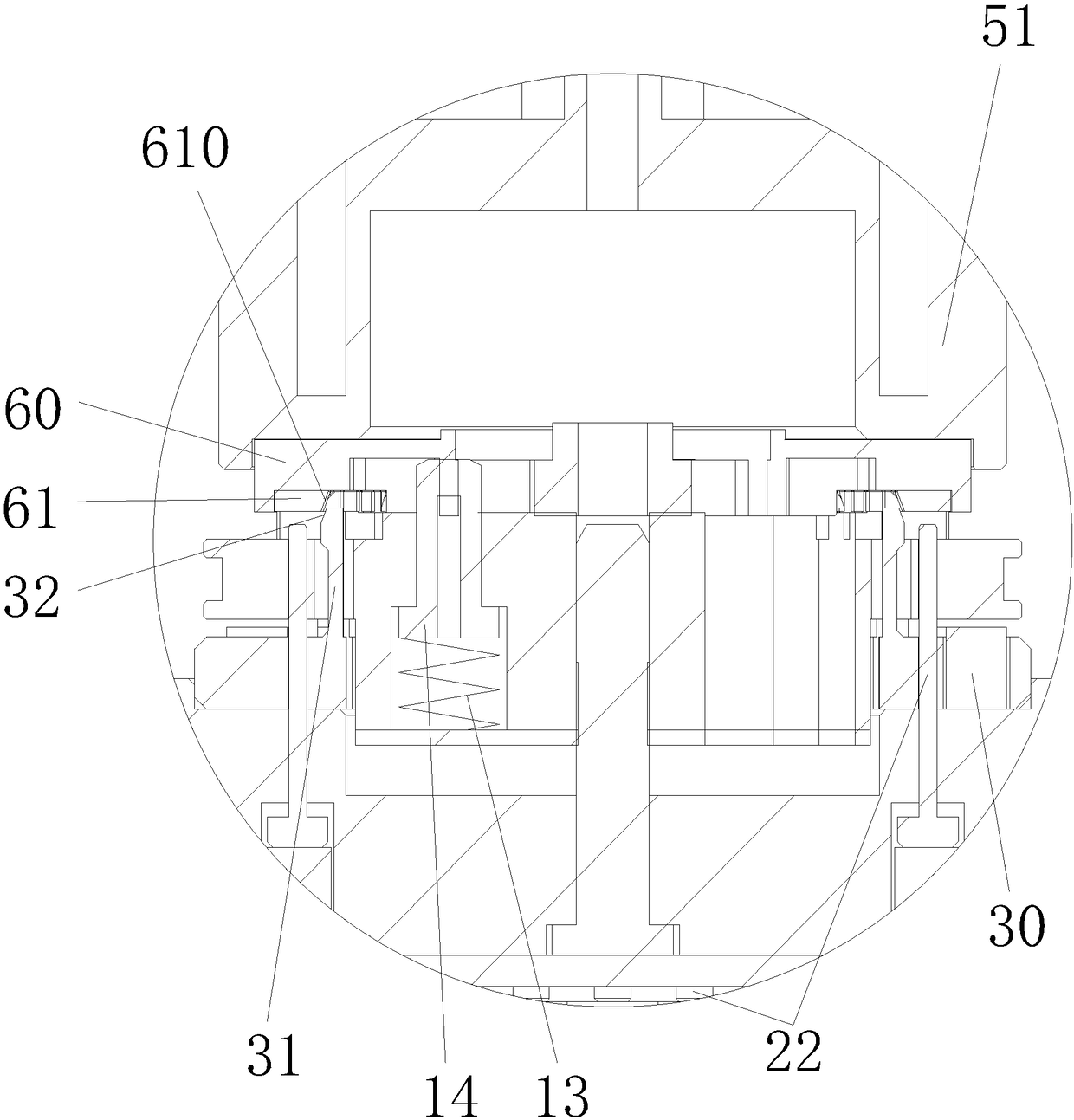

[0025] The above-mentioned upper bracket 12 is provided with a vertically downward downward driving source 50 , and a suction cup 51 is provided at the shaft end of the downward driving source 50 . The suction cup 51 has an inwardly recessed receiving cavity, the inner diameter of which is consistent with the outer diameter of the rotor 60 . The suction cup 51 has certain magnetism, and it can attract the rotor 60 . The pressing driving source 50 can drive the suction cup 51 to move up and down.

[0026] The above-mentioned lower bracket 11 is provided with a spring 13 and an expansion flap disc 30 . A support column 14 is arranged on the spring 13, and a convex ring protrudes radially from the lower part thereof. There are three support columns 14, which are evenly distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com