Semi-automatic pasting machine for wallpaper pasting

A semi-automatic laminating machine technology, which is applied in decorative art, paper pasting, etc., can solve the problems of troublesome construction, laborious, time-consuming bubbles, etc., and achieve the effect of ensuring linear flatness, improving pasting quality, and avoiding bubbles or wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

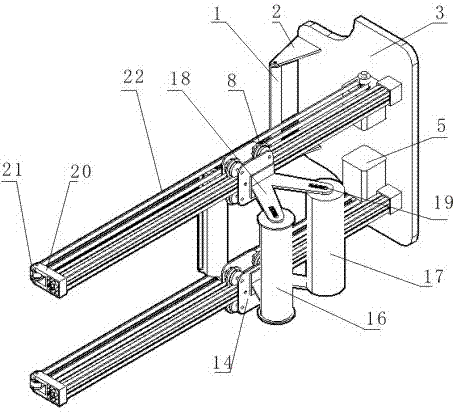

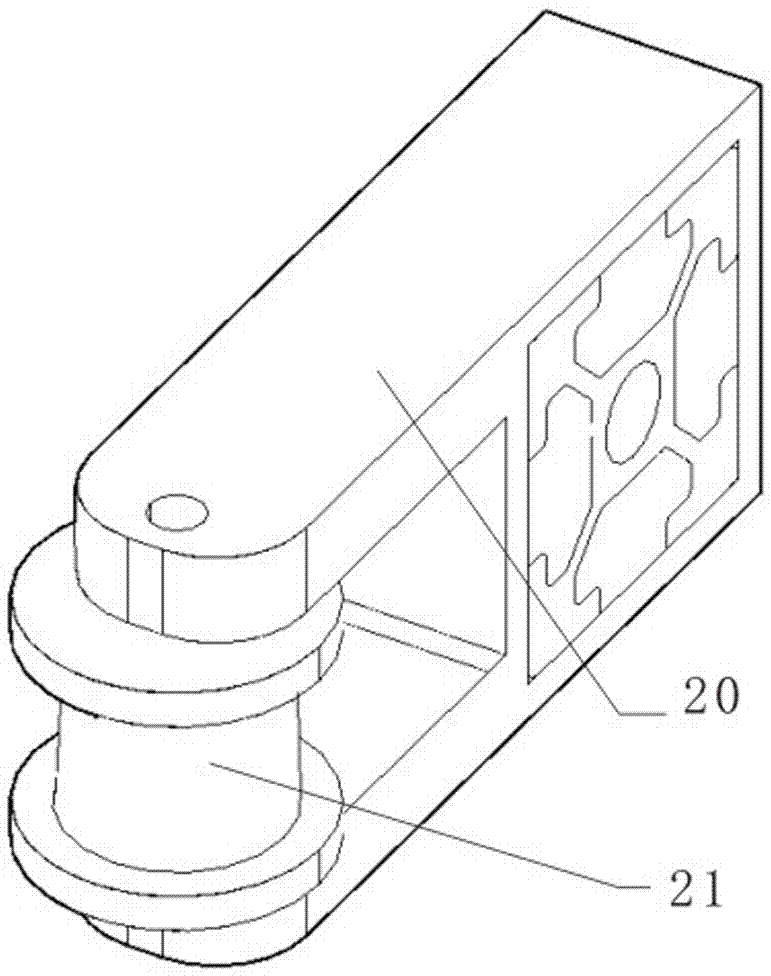

[0028] combined with figure 1 As shown, a semi-automatic laminating machine for wallpaper lamination includes a base plate 3 for positioning the ground and the wall, a mounting seat 2 fixedly connected to the base plate 3, and the mounting base 2 is installed There is a wallpaper reel 1 for holding wallpaper, and the base plate 3 is also fixedly provided with two slide rails 7 perpendicular to the base plate 3 and parallel to each other, and a wallpaper bonding mechanism is slidably connected between the slide rails 7; A synchronous wheel 21 is installed on the end of the slide rail 7 away from the bottom plate 3, and a belt 22 is sleeved on the synchronous wheel 21, and the belt 22 is driven by the driving motor 5 installed on the bottom plate 3; The belt 22 is detachably and fixedly connected to the wallpaper pasting mechanism.

[0029]Working principle and method of use, when using the present invention, first place the lower surface of the base plate 3 flush with the grou...

Embodiment 2

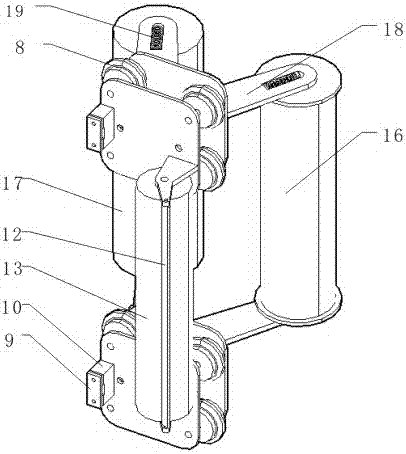

[0031] In order to better realize the present invention, in conjunction with the attached Figure 1-4 As shown, on the basis of the structure and principle of Embodiment 1, in this embodiment, the wallpaper pasting mechanism includes a pulley that is slidably connected to the slide rail 7, and the side of the pulley away from the wallpaper reel 1 can be Disassemble the connected roller bracket 18, install the tiling roller 16 and pressing roller 17 for pasting wallpaper on the roller bracket 18, and the side of the pulley near the wallpaper reel 1 is detachably connected with a protective film for separating the wallpaper The peeling roller 13. In order to overcome the problem that the existing wallpaper pasting device is not easy to separate and recycle the wallpaper protective film, the peeling roller 13 added by the present invention can automatically separate the bonded wallpaper, and after separation, the wallpaper is flattened by the flat roller 16. Fit the wallpaper on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com