Trimming device for fireproof door frame

A technology for fire doors and door frames, used in manufacturing tools, wood processing appliances, bark areas/debris/dust/waste removal, etc. problems, to achieve the effect of improving the quality of the paste and the suction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

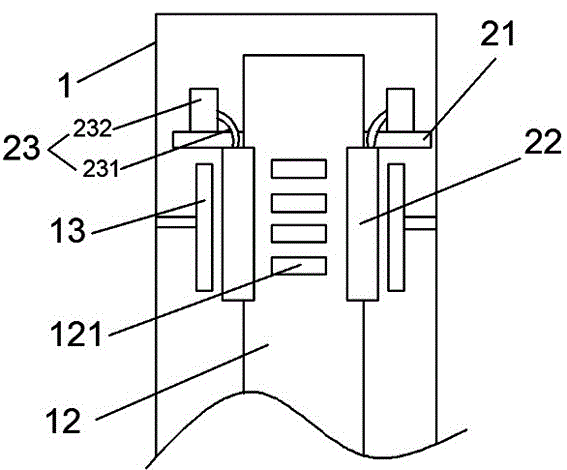

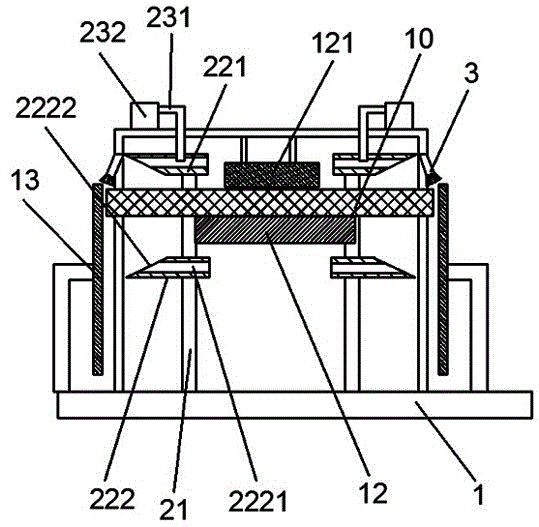

[0013] A trimming device for a fire door frame, as attached figure 1 , 2 As shown, it includes a bracket 1, a door panel delivery platform 12 arranged on the bracket 1 and a trimming disc 13 driven by a motor installed on the bracket 1. The top of the delivery platform 12 is provided with a pressure roller 121 for pressing the door frame 10, and the door frame Place it on the conveying platform 12 and drive it to transport forward, while the trimming discs 13 on both sides trim it. For the convenience of trimming, the door frame 10 will exceed the both sides of the conveying platform 12. An auxiliary structure is also provided on the support 1, including a support rod 21 fixed on the support 1 and an auxiliary block 22 fixed on the support rod 21 by screws. The auxiliary block 22 includes an upper auxiliary block 221 and a lower auxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com