Universal quantitative pressure application system for pasting rod type wind tunnel strain balance

A technology of strain balance and pressurization system, which is applied in the direction of measuring devices, instruments, aerodynamic tests, etc., can solve problems such as the inability to realize universal application of pasting fixtures, lack of quantitative pressurization function, poor interchangeability of pasting fixtures, etc., and achieve a solution Poor versatility and insufficient single pressure component, improved paste quality and efficiency, and accurate and reliable measured values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

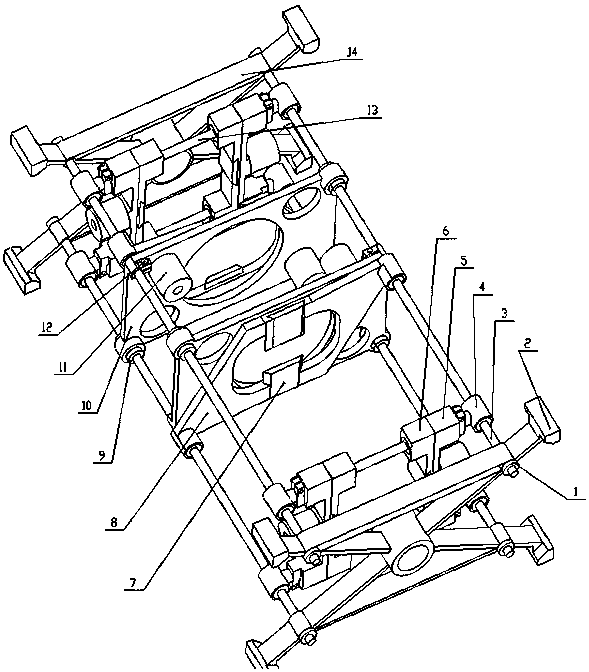

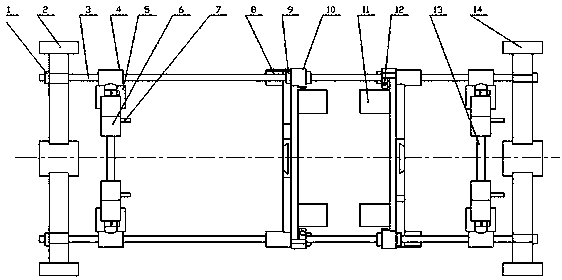

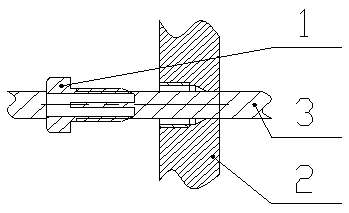

[0030] figure 1 and figure 2 Shown is the overall layout of the quantitative pressurization system of the invention. According to the working effects of each component, the quantitative pressurization system is divided into several parts: support connection parts, radial force application parts and axial force application parts. The four main shafts connect and fix the front support base and the rear support base to form the basic frame of the entire support part. The force applying part moves freely on the main shaft, and when it reaches the designated force applying position, it is fixed by the locking device on the force applying part. Apply a constant amount of force. Depend on figure 1 It can be seen intuitively that the axial force application system and the radial force applicatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com